Corrosion protection method of fluoride molten salt and/or chloride molten salt and application of chrome

A molten salt corrosion and chloride technology, applied in the field of material corrosion protection, can solve problems such as corrosion, inability to form a protective surface film, thermodynamic instability, etc., to reduce corrosion rate, slow down intergranular corrosion problems, and be easy to operate and control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

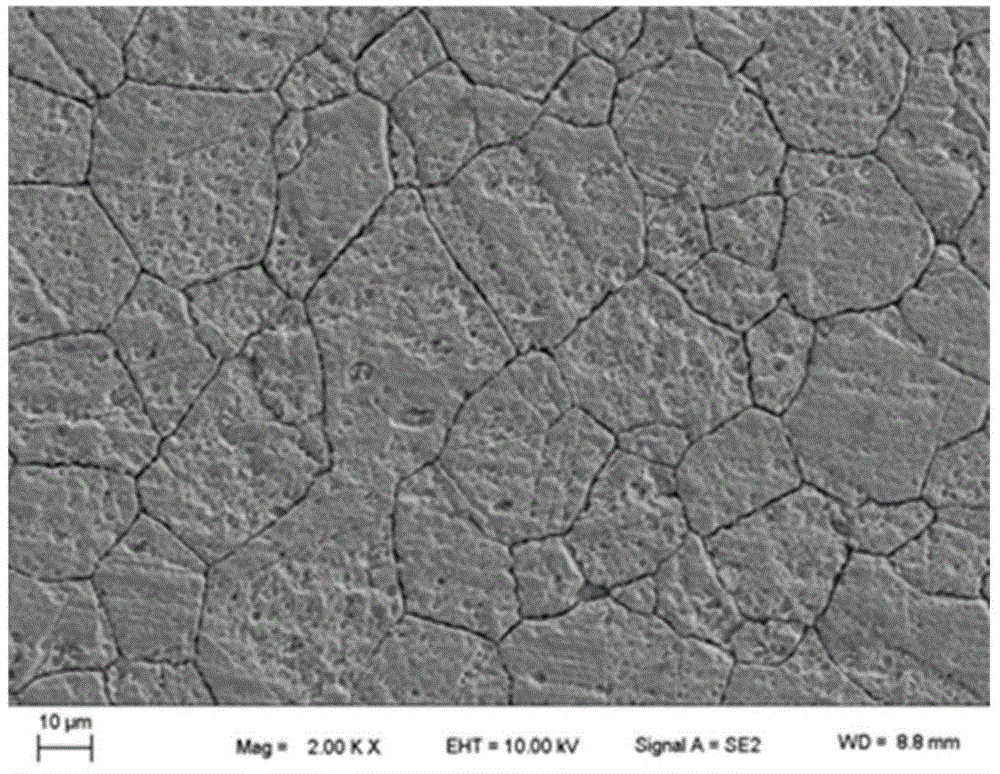

Image

Examples

Embodiment 1

[0041] The molten salt system in this embodiment is a static constant temperature system.

[0042] 1. Pretreatment of 316L stainless steel and chromium

[0043] 316L stainless steel and chromium (99.9wt%) were cut into samples with a size of 30 mm × 10 mm × 2 mm by wire cutting method, and a diameter of 316L stainless steel was punched on the sample. hole. The surface of all samples was polished step by step with SiC sandpaper to 2000 mesh, then ultrasonically cleaned with deionized water and absolute ethanol in sequence, and dried with a hair dryer and cold air.

[0044] 2. Corrosion protection method of 316L stainless steel in 700°C FLiNaK molten salt

[0045] figure 1 It is a schematic diagram of the corrosion protection test device in Example 1; wherein, 1 is a 316 stainless steel crucible, 2 is a graphite crucible, 3 is FLiNaK molten salt, 4 is pure chromium, 5 is a 316L stainless steel sample, and 6 is 316L stainless steel wire, 7 for alumina ceramic sheet.

[004...

Embodiment 2

[0049] The molten salt system in this embodiment is a static constant temperature system.

[0050] 1. Pretreatment of 316L stainless steel and chromium

[0051] 316L stainless steel and chromium (99.9wt%) were cut into samples with a size of 30mm×10mm×2mm by wire cutting method, and a diameter of hole. The surface of all samples was polished step by step with SiC sandpaper to 2000 mesh, then ultrasonically cleaned with deionized water and absolute ethanol in sequence, and dried with a hair dryer and cold air.

[0052] 2. Corrosion protection method of 316L stainless steel in 700°C FLiNaK molten salt

[0053] figure 2 It is a schematic diagram of the corrosion protection test device in Example 2; wherein, 1 is a 316 stainless steel crucible, 2 is a graphite crucible, 3 is FLiNaK molten salt, 4 is pure chromium, 5 is a 316L stainless steel sample, and 6 is 316L stainless steel wire, 7 for alumina ceramic sheet.

[0054] Combine 316L stainless steel with chrome in accorda...

Embodiment 3

[0057] The molten salt system in this embodiment is a static constant temperature system.

[0058] 1. Pretreatment of 316 stainless steel and chromium

[0059] 316 stainless steel and chromium (99.9wt%) were cut into samples with a size of 30mm × 10mm × 2mm by wire cutting method, and each sample was punched with a diameter of hole. The surface of all samples was polished step by step with SiC sandpaper to 2000 mesh, then ultrasonically cleaned with deionized water and absolute ethanol in sequence, and dried with a hair dryer and cold air.

[0060] 2. 316 stainless steel at 800°C NaF-ZrF 4 Corrosion protection methods in molten salt

[0061] 316 stainless steel and chromium were added to the experimental crucible, and the 316 stainless steel and chromium were kept in direct contact. Add 550g NaF-ZrF to the crucible 4 (59.5-40.5mol%) molten salt, make the chromium part soak in the molten salt system, cover the graphite cover, put the graphite crucible into the outer layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com