A preparation of high performance aginte 2 Thermoelectric Materials Approach

A high-performance technology for thermoelectric materials, applied in the field of preparation of high-performance AgInTe2 thermoelectric materials, can solve the problems of difficult control of the single-phase state of the product, unstudied thermoelectric properties, and complex sources of raw materials, etc., to achieve good product composition, short preparation cycle, and raw materials The effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation of high-performance AgInTe 2 A method for thermoelectric materials, comprising the steps of:

[0034] 1) According to the chemical formula (Ag 2 Te) 1-x (In 2 Te 3 ) x The stoichiometric ratio of each element in (x=0.50) takes Ag wire, In particle and Te block as raw material,

[0035] 2) Vacuum-seal the block obtained in step 1) into a quartz glass tube, then place it in a melting furnace, raise the temperature to 1000°C at 2°C / min and keep it warm for 24h, and quench it in saturated brine to obtain an ingot;

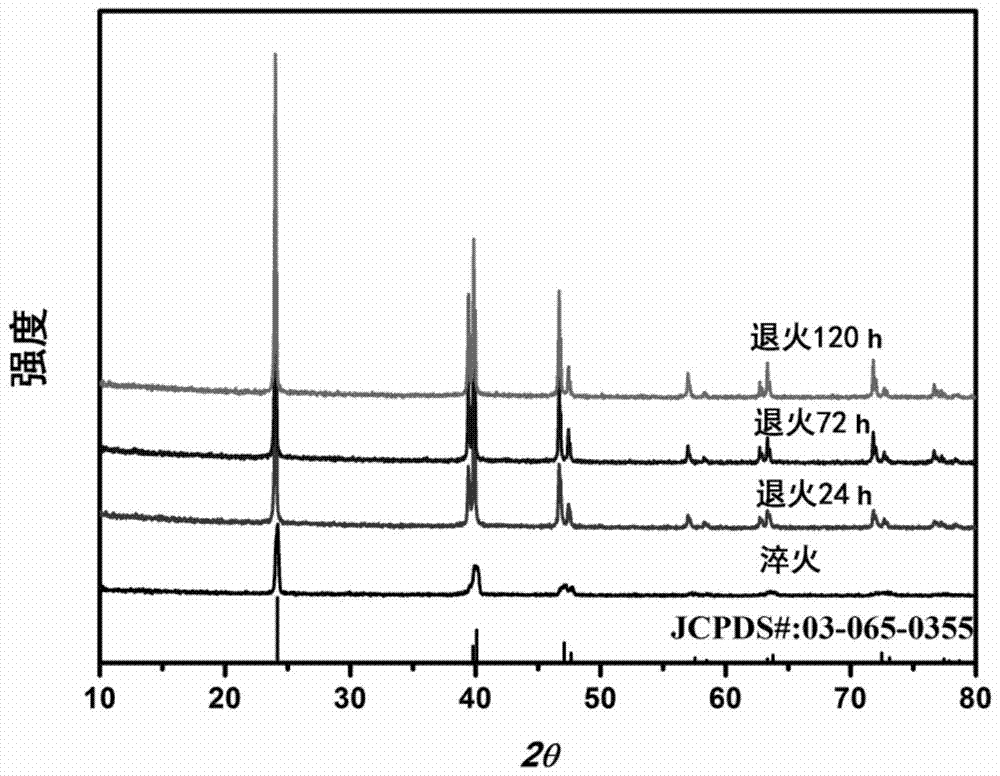

[0036] 3) Vacuum-seal the ingot body obtained in step 2) into a quartz glass tube, raise the temperature in a muffle furnace at 3°C / min to 400°C for 24h, 72h and 120h respectively, and then air cool to room temperature;

[0037]4) Grind the ingot obtained in step 3) into powder, and perform plasma-activated sintering (PAS): put the obtained powder into a graphite mold with a diameter of 16mm for compaction, and then under the conditions of a ...

Embodiment 2

[0041] A method for preparing high-performance AgInTe2 thermoelectric material, it comprises the following steps:

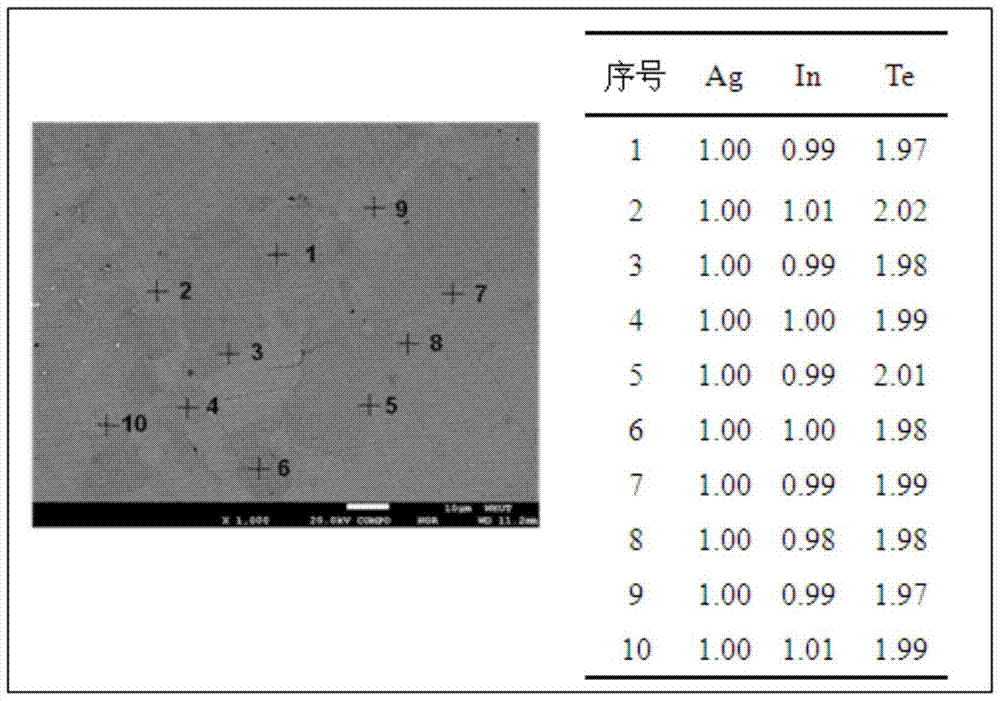

[0042] 1) According to the chemical formula AgInTe 2 The stoichiometric ratio of each element in the method weighs Ag wire, In particles and Te block as raw materials;

[0043] 2) Vacuum-seal the block obtained in step 1) into a quartz glass tube, then place it in a melting furnace, raise the temperature to 1000°C at 2°C / min and keep it warm for 24h, and quench it in saturated brine to obtain an ingot;

[0044] 3) Vacuum-seal the ingot body obtained in step 2) into a quartz glass tube, and raise the temperature to 400°C in a muffle furnace at 3°C / min for 72h;

[0045] 4) Grinding the obtained product in step 3) into powder, performing plasma activated sintering (PAS), packing the powder into a graphite mold with a diameter of 16 mm for compaction, and then sintering under the condition that the vacuum degree is less than 10 Pa and the sintering pressure is 45 MP...

Embodiment 3

[0049] A preparation of high-performance AgInTe 2 A method for thermoelectric materials, comprising the steps of:

[0050] 1) According to the chemical formula (Ag 2 Te) 1-x (In 2 Te 3 ) x The stoichiometric ratio of each element in the scale takes Ag wire, In particles and Te blocks as raw materials, where x is 0.50, 0.52, 0.54 and 0.56 respectively, that is, AgInTe 2 ;

[0051] 2) Vacuum-seal the raw material obtained in step 1) into a quartz glass tube, then place it in a melting furnace, raise the temperature to 1000°C at a rate of 2°C / min and keep it for 24h, and then quench it in saturated brine to obtain an ingot;

[0052] 3) Vacuum-seal the ingot body obtained in step 2) into a quartz glass tube, then place it in a muffle furnace and heat it up to 400°C at a rate of 3°C / min for 72h;

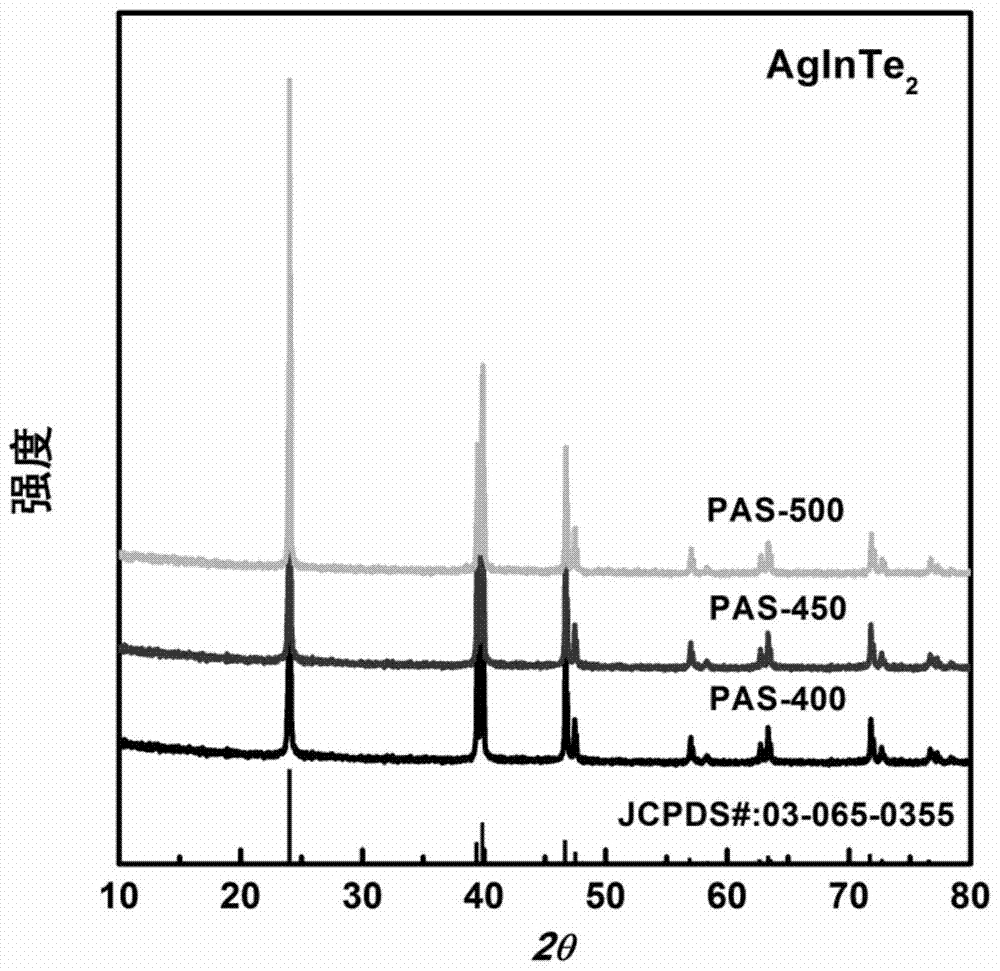

[0053] 4) Grind the product obtained in step 3) into powder and carry out plasma activation sintering (PAS). Sintering under the conditions of 100°C / min to 450°C at a heating rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com