Preparation methods of fluorosilicate red fluorescent powder and composition containing fluorescent powder, products and applications

A technology of red fluorescent powder and fluorosilicate, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of low absorption intensity of fluorescent materials, difficulty in research of fluorescent powder materials, and complicated production process, etc., to achieve luminescence Stable performance, easy long-term storage, and stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This example is used to illustrate the preparation method of the fluorosilicate red phosphor powder provided by the present invention, and the red phosphor powder prepared by this method.

[0037] (1) 2.6gKMnO 4 (purchased from Yantai Sanhe Chemical Reagent Co., Ltd.) and 20.3g KF were added into 260ml (60vol%) hydrofluoric acid and stirred for 15min until uniformly mixed, then added H 2 o 2 Until the color of the solution changes, a mixed solution is obtained;

[0038] (2) Add 10 g of powdered quartz glass to the mixed solution obtained in step (1), heat to 60° C., keep warm for 2 hours, cool down to 20° C. in a water bath, continue stirring for 12 hours, and obtain a yellow solid after filtration;

[0039] (3) Wash the yellow solid obtained in step (2) with a small amount of deionized water and absolute ethanol, and dry at 150° C. to obtain 6 g of the red phosphor.

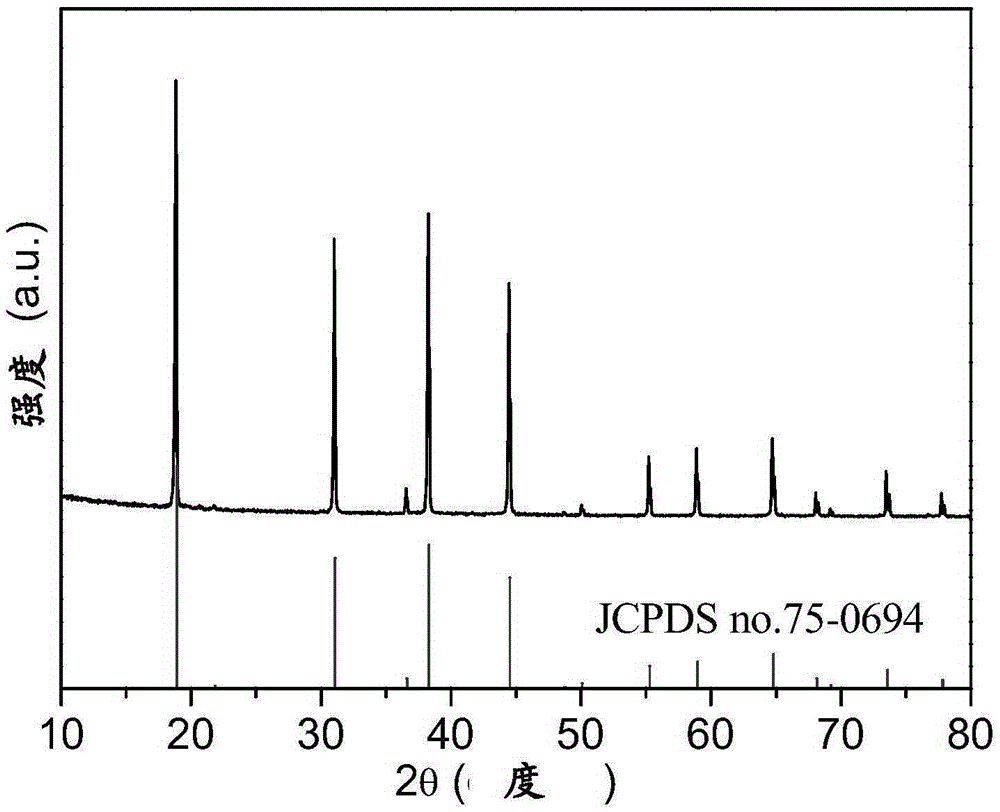

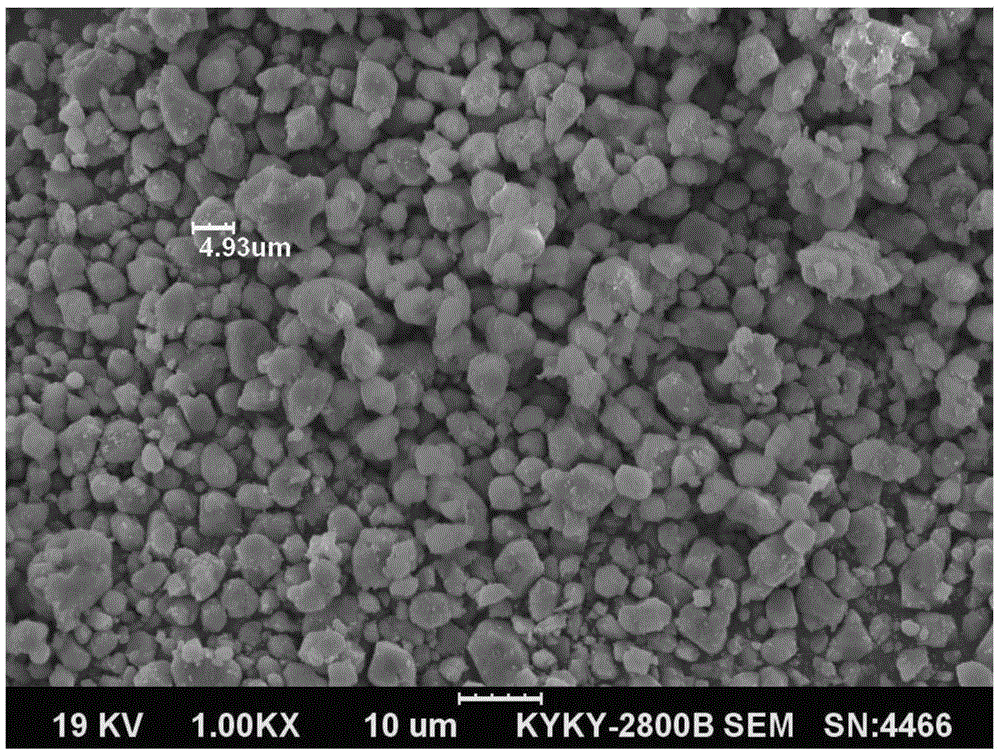

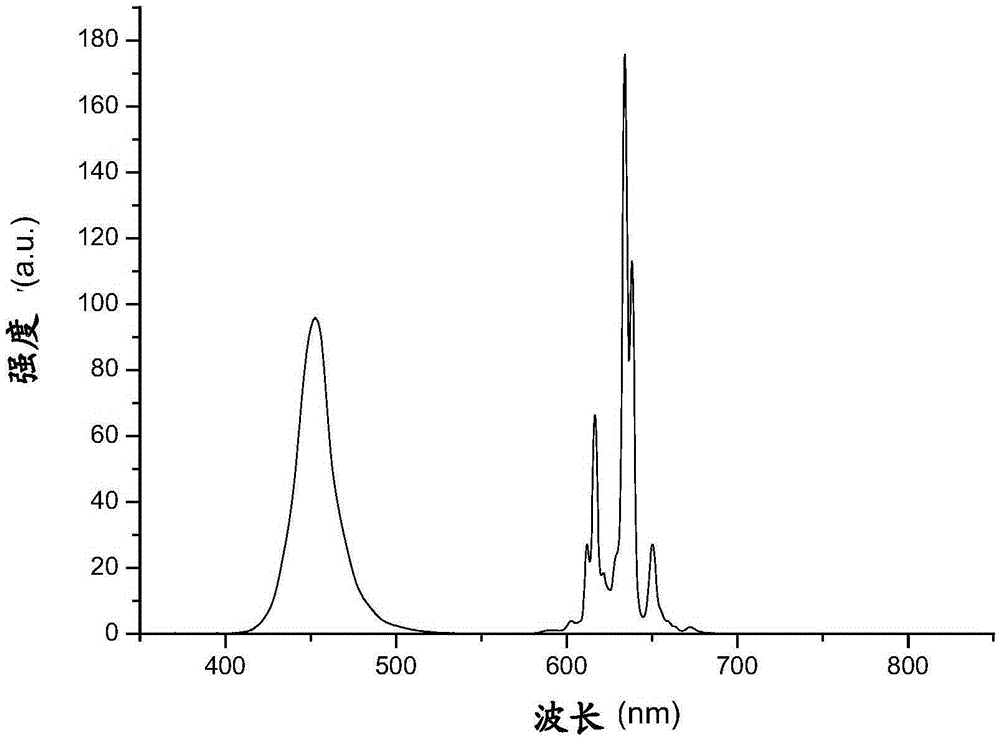

[0040] Measure the XRD pattern (see figure 1 ), indicating that it has the same K 2 SiF 6 corres...

Embodiment 2

[0045] This example is used to illustrate the preparation method of the fluorosilicate red phosphor powder provided by the present invention, and the red phosphor powder prepared by this method.

[0046] (1) 2.6gKMnO 4 (purchased from Yantai Sanhe Chemical Reagent Co., Ltd.) and 20.3g KF were added into 260ml (60vol%) hydrofluoric acid and stirred for 15min until uniformly mixed, then added H 2 o 2 Until the color of the solution changes, a mixed solution is obtained;

[0047] (2) Add 10 g of powdered borosilicate glass to the mixed solution obtained in step (1), heat to 50° C., keep warm for 3 hours, cool down to 30° C. in a water bath, continue stirring for 3 hours, and obtain a yellow solid after filtration;

[0048] (3) Wash the yellow solid obtained in step (2) with a small amount of deionized water and absolute ethanol, and dry at 150° C. to obtain 6 g of the red phosphor.

[0049] Measure the XRD figure of gained powder by X-ray powder diffractometer (model D8-ADVANC...

Embodiment 3

[0051] This example is used to illustrate the preparation method of the fluorosilicate red phosphor powder provided by the present invention, and the red phosphor powder prepared by this method.

[0052] (1) 2.6gKMnO 4 (purchased from Yantai Sanhe Chemical Reagent Co., Ltd.) and 20.3gKF were added into 52ml (60vol%) hydrofluoric acid and stirred for 15min until they were evenly mixed, and H 2 o 2 Until the color of the solution changes, a mixed solution is obtained;

[0053] (2) Add 10 g of powdered quartz glass to the mixed solution obtained in step (1), heat to 70° C., keep warm for 1 hour, cool down to 10° C. in a water bath, continue to stir for 8 hours, and obtain a yellow solid after filtration;

[0054] (3) Wash the yellow solid obtained in step (2) with a small amount of deionized water and absolute ethanol, and dry at 150° C. to obtain 6 g of the red phosphor.

[0055] Measure the XRD figure of gained powder by X-ray powder diffractometer (model D8-ADVANCE, purchas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com