Modified polyurethane resin coating and preparation method thereof

A polyurethane resin and coating technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of no stimulus-responsive release of corrosion inhibitors, coating foaming, and damage to coating integrity. Achieve superior coating function and stability, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

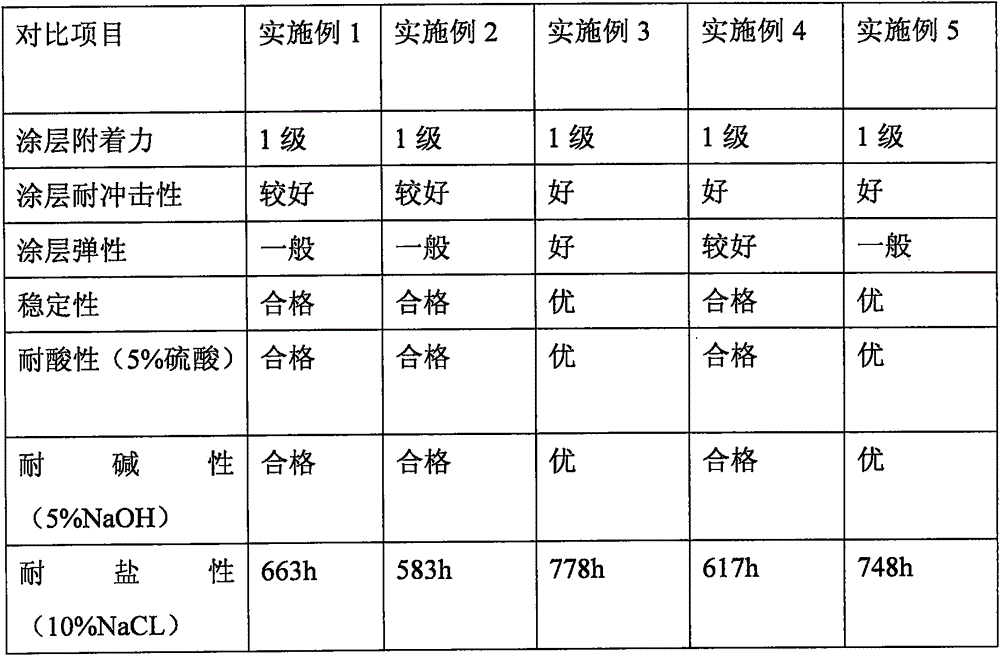

Examples

preparation example Construction

[0015] The preparation method of this coating is as follows:

[0016] 1) Add 60-80 parts of toluene diisocyanate, 5-10 parts of dicyclohexylmethane diisocyanate, 5-10 parts of hexamethylene diisocyanate, and 5-10 parts of ethyl acetate into the reaction kettle, and use a mixer to fully stir, Raise the temperature to 90-100°C, slowly add 4-8 parts of adipic acid;

[0017] 2) Continue to add 1-5 parts of alkyd resin, 2-4 parts of epoxy resin, stir well for more than 1 hour,

[0018] 3) Add chain extender, activator and catalyst: Add 1-3 parts of propylene glycol, 1-3 parts of methyldiethanolamine, 1-4 parts of dibutyltin diesterate, and 0.5-1 part of phosphoric acid in four equal intervals of 30 minutes , then keep warm at 80 degrees Celsius for more than 4 hours, add ionized water for emulsification for more than 30 minutes;

[0019] 4) The polymer nanoparticles coated with benzotriazole are dispersed and mixed in the above emulsion by ultrasonic dispersion, fully stirred and...

Embodiment 1

[0026] Polyurethane resin-nanoparticle composite coating is made from the following raw materials according to the weight ratio: 60 parts of toluene diisocyanate, 5 parts of dicyclohexylmethane diisocyanate, 5 parts of hexamethylene diisocyanate, 4 parts of adipic acid, alkyd resin 1 part, 2 parts of epoxy resin, 1 part of propylene glycol, 1 part of methyldiethanolamine, 1 part of dibutyltin diesterate, 6 parts of ethyl acetate, 0.5 part of phosphoric acid, 15 parts of deionized water; and 8 parts of polymer nanoparticles share. The preparation method is as described above.

Embodiment 2

[0028] Polyurethane resin-nanoparticle composite coating is made from the following raw materials according to the weight ratio: 70 parts of toluene diisocyanate, 10 parts of dicyclohexylmethane diisocyanate, 10 parts of hexamethylene diisocyanate, 8 parts of adipic acid, alkyd resin 3 parts, 4 parts of epoxy resin, 3 parts of propylene glycol, 2 parts of methyldiethanolamine, 4 parts of dibutyltin diester, 10 parts of ethyl acetate, 0.5 parts of phosphoric acid, 30 parts of deionized water; and 10 parts of polymer nanoparticles share. The preparation method is as described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com