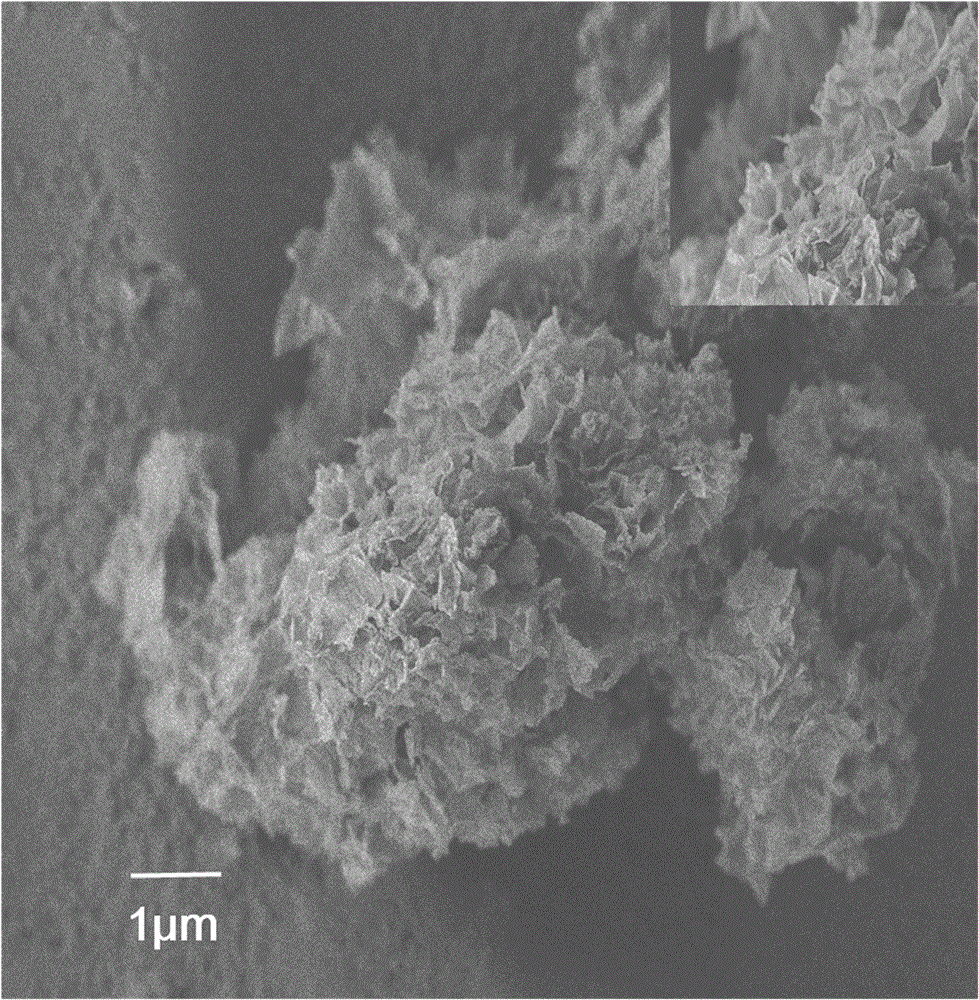

Tremelliform ferric phosphate and preparation method therefor

A technology of iron phosphate and tremella, applied in chemical instruments and methods, phosphorus compounds, structural parts, etc., can solve problems such as low ion and electronic conductivity, low temperature, and poor rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] According to the stoichiometric ratio of iron and phosphorus in the target product 1:1.05, the quality of the surfactant is 0.05% of the mass of the iron source, and the molar ratio iron source:hydrogen peroxide=1:1, respectively weigh ferrous sulfate, phosphoric acid, hexadecane base trimethylammonium bromide, measure the corresponding hydrogen peroxide (30%). Dissolve cetyltrimethylammonium bromide and ferrous sulfate in isopropanol and deionized water respectively, pour the mixture of the two into a good amount of hydrogen peroxide, and ultrasonicate at a constant temperature of 40°C for 5 minutes to form 0.05M ferric sulfate glue Beam solution A. Dissolve the weighed phosphoric acid in deionized water, and ultrasonicate at a constant temperature of 40°C for 5 minutes to prepare 0.05M phosphoric acid solution B. Pour the prepared B into A, continue to sonicate for 5 minutes, quickly transfer to the lining of a 100ml autoclave with a filling degree of 70%, tighten it...

Embodiment 2

[0029] According to the stoichiometric ratio of iron and phosphorus in the target product 1:1.02, the mass of the surfactant is 0.1% of the mass of the iron source, and iron nitrate, phosphoric acid, and polyvinylpyrrolidone are weighed respectively. Dissolve the surfactant and ferric nitrate in deionized water, and ultrasonicate at a constant temperature of 50°C for 5 minutes to prepare 0.1M ferric sulfate micellar solution A. Dissolve the weighed phosphoric acid in deionized water, and ultrasonicate at a constant temperature of 50°C for 5 minutes to prepare 0.05M phosphoric acid solution B. Pour the above prepared B into A, continue to sonicate for 5 minutes, quickly transfer to the lining of a 100ml autoclave with a filling degree of 60%, tighten it, and put it in an oven at 100°C for 6 hours for hydrothermal reaction. After the reaction, turn off the oven, let it cool down to room temperature naturally, turn on the autoclave, transfer the mixture to a centrifuge tube, cent...

Embodiment 3

[0036] Replace the iron source, phosphorus source, and surfactant with ferric sulfate and ammonium hydrogen phosphate respectively, and the ratio remains unchanged. According to the method in Example 2, tremella-shaped iron phosphate is first synthesized, and then the synthesized iron phosphate is used as the iron source to synthesize phosphoric acid. Lithium iron material for half-battery production.

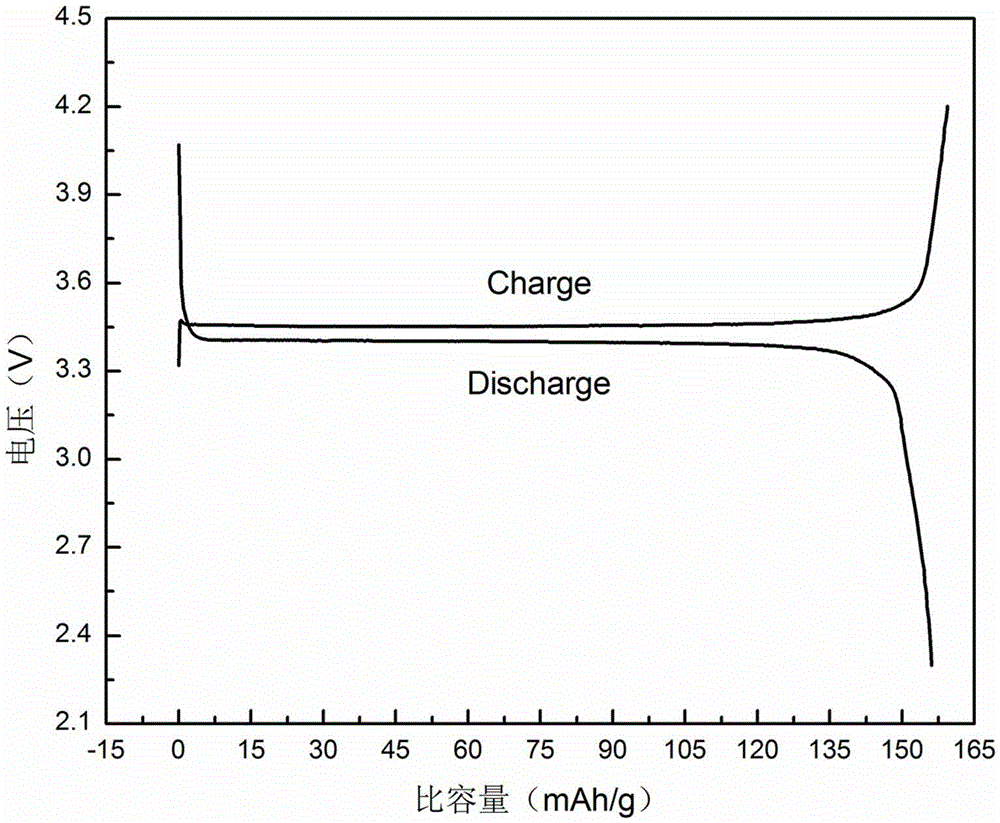

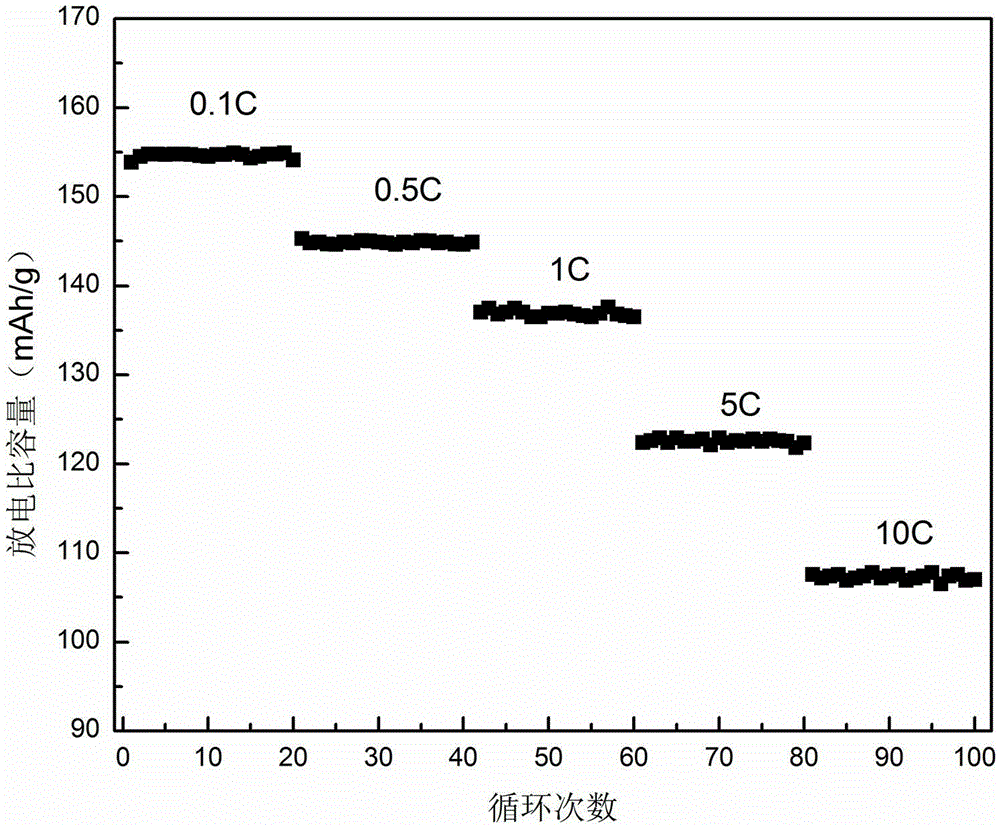

[0037] image 3 The charge-discharge diagrams of the half-cells assembled in this example at different rates in the range of 2.3-4.2V, the lithium iron phosphate synthesized by this method shows excellent rate and cycle performance, and the discharge specific capacity at 10C is 0.1C 69.8% of the specific capacity under discharge is 77.9% of the specific capacity under 1C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com