Preparation method of multilevel structure titanate negative electrode material for lithium ion battery

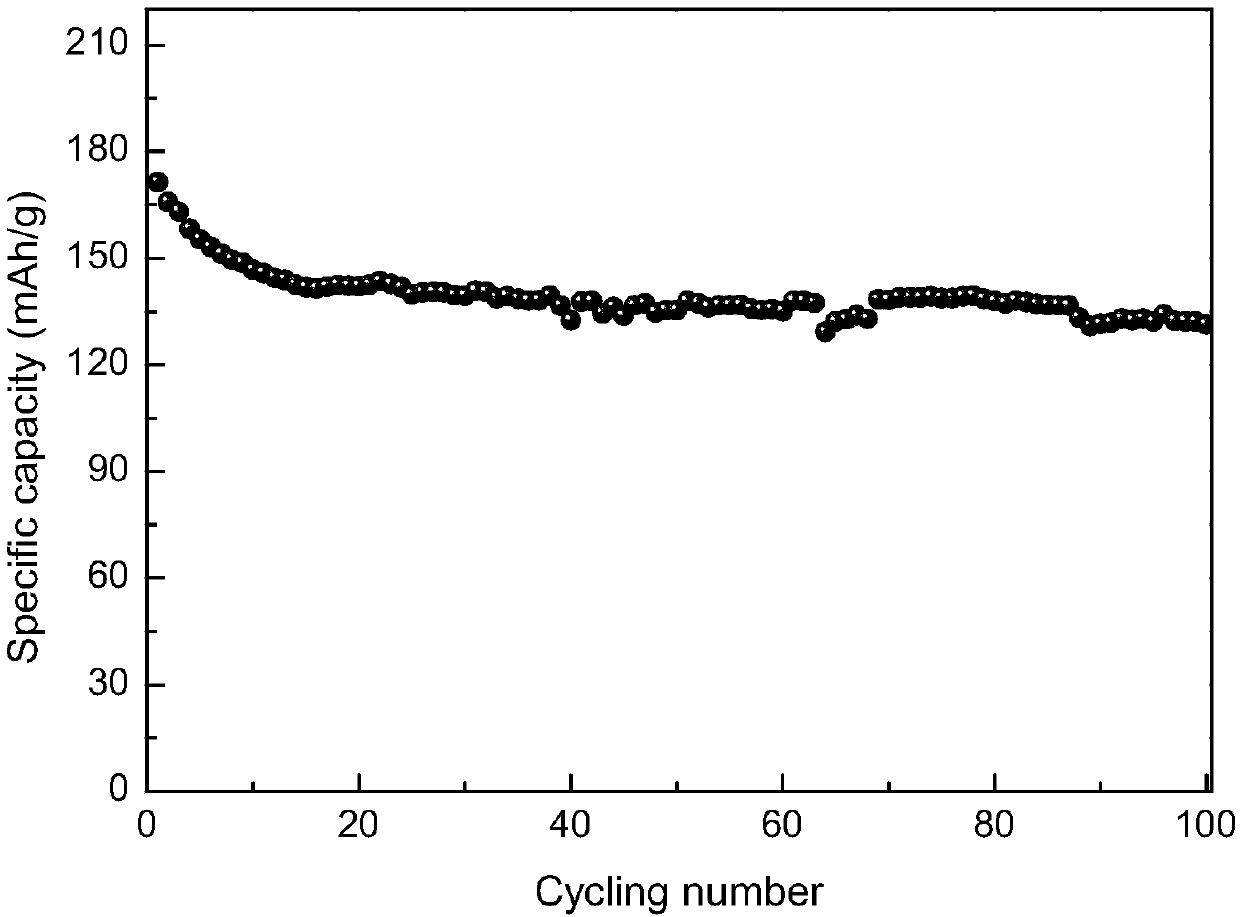

A technology for structural titanate, lithium ion batteries, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problem of reducing full battery energy density, low lithium ion diffusion rate, low theoretical capacity and other issues, to achieve the effects of excellent rate performance, cheap and easy availability of raw materials, and improved energy density and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Disperse 0.06mol tetrabutyl titanate and 0.02mol sodium acetate in a mixed solution of ethylene glycol and absolute ethanol (volume ratio 1:1), and stir for 5-8 hours to obtain solution A; dissolve 0.01mol barium nitrate in The aqueous solution of ethanol (volume ratio 1:1) is solution B. The solutions A and B were quickly mixed and vigorously stirred, and the temperature was raised to 80°C. After the liquid was evaporated to dryness, it was placed in a vacuum drying oven at 90°C for 12 hours in vacuum. Then put the precursor in a muffle furnace at 400°C for 6 hours, cool to room temperature, mill in a ball mill for 4 hours, sieve, put it in a muffle furnace and burn at 1000°C for 12 hours, cool to room temperature, and ball mill 24h, the lithium-ion battery negative electrode material BaNa 2 Ti 6 o 14 Material. Take 10g of the resulting BaNa 2 Ti 6 o 14 The material is dispersed into an acetone solution, and 0.2 g of ordinary multi-walled carbon nanotubes (CNT, ...

Embodiment 2

[0017] Disperse 0.06mol tetrabutyl titanate and 0.02mol sodium nitrate in a mixed solution of ethylene glycol and absolute ethanol (volume ratio 1:1), and stir for 5 hours to obtain solution A; dissolve 0.01mol barium acetate in ethanol Aqueous solution (volume ratio 1:1), namely solution B. The solutions A and B were quickly mixed and vigorously stirred, and the temperature was raised to 80°C. After the liquid was evaporated to dryness, it was placed in a vacuum drying oven at 90°C for 12 hours in vacuum. Then put the precursor in a muffle furnace at 400°C for 4 hours, cool to room temperature, ball mill in a ball mill for 3 hours, sieve, put it in a muffle furnace and burn at 900°C for 10 hours, cool to room temperature, and ball mill 24h, the lithium-ion battery negative electrode material BaNa 2 Ti 6 o 14 Material. Take 10g of the resulting BaNa 2 Ti 6 o 14 The material is dispersed into an acetone solution, and 0.1g of carbon nanotubes (CNT, diameter 30-50μm, bulk ...

Embodiment 3

[0019] Disperse 0.02mol sodium nitrate and 0.06mol isopropyl titanate in a mixed solution of ethylene glycol and absolute ethanol (volume ratio 1:1), and stir for 8 hours to obtain solution A; dissolve 0.01mol barium acetate in ethanol Aqueous solution (volume ratio 1:1), namely solution B. The solutions A and B were quickly mixed and vigorously stirred, and the temperature was raised to 80°C. After the liquid was evaporated to dryness, it was placed in a vacuum drying oven at 120°C for vacuum drying for 12 hours. Then put the precursor in a muffle furnace at 600°C for 6 hours, cool to room temperature, mill in a ball mill for 4 hours, sieve, put it in a muffle furnace and burn at 1100°C for 15 hours, cool to room temperature, and ball mill 24h, the lithium-ion battery negative electrode material BaNa 2 Ti 6 o 14 Material. Take 10g of the resulting BaNa 2 Ti 6 o 14 The material is dispersed into an acetone solution, and 0.5g of carbon nanotubes (CNT, diameter 30-50μm, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com