Manufacturing method for paint-emery inkstone

A production method and paint ash technology, applied in decorative arts, printing, office supplies, etc., can solve the problems of easy sinking of emery, excessive ink grinding sound, and inability to use pens, so as to improve the stability of wood and expand options. Scope, the effect of shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

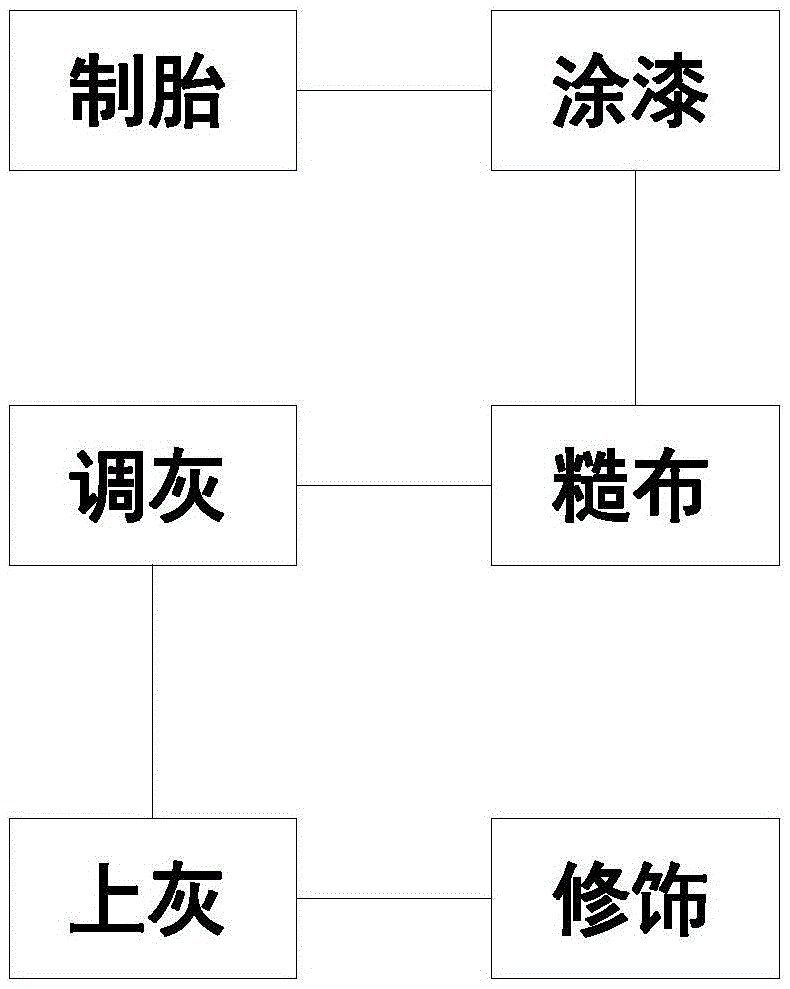

[0043] see figure 1 , a method for making lacquer-sand inkstone, comprising six major steps of tire making, painting, rough cloth, graying, dusting, and modification. The specific operation steps are as follows:

[0044] ① Tire making: use light, dry, stable wood, and fine-structured nanmu as the raw material, then cut the nanmu into a wooden billet of appropriate size, and use a carving knife to dig on the wooden billet according to the designed lacquer sand inkstone pattern. Finally, use wood sandpaper to smooth the chisel marks on the billet, and sand the surface of the billet to make a wooden tire.

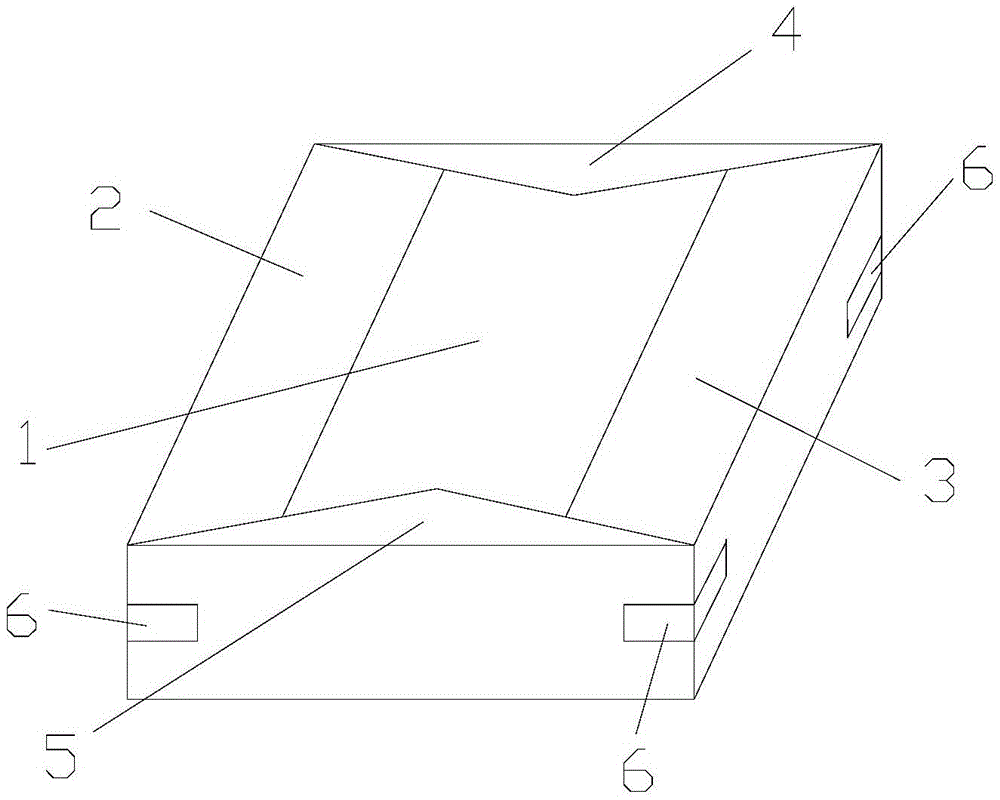

[0045] The above-mentioned wooden blanks adopt a splicing design, which includes a central blank 1 , a first blank 2 , a second blank 3 , a first V-shaped blank 4 and a second V-shaped blank 5 . Wherein, the central block 1 is hexagonal, its upper and lower ends are V-shaped, and its left and right ends are straight. The first block 2 and the second block 3 are symmetrically...

Embodiment 2

[0061] see figure 2 , a method for making lacquer-sand inkstone, comprising six major steps of tire making, painting, rough cloth, graying, dusting, and modification. The specific operation steps are as follows:

[0062] ① Tire making: take sycamore wood with light, dry, stable wood and fine structure as the raw material, then cut the sycamore wood into a suitable size wood billet, and use a carving knife to carve the wood billet according to the designed lacquer sand inkstone pattern Carry out digging, and finally use wood sandpaper to smooth the chisel marks on the wood billet, and sand the surface of the wood billet to make a wooden tire.

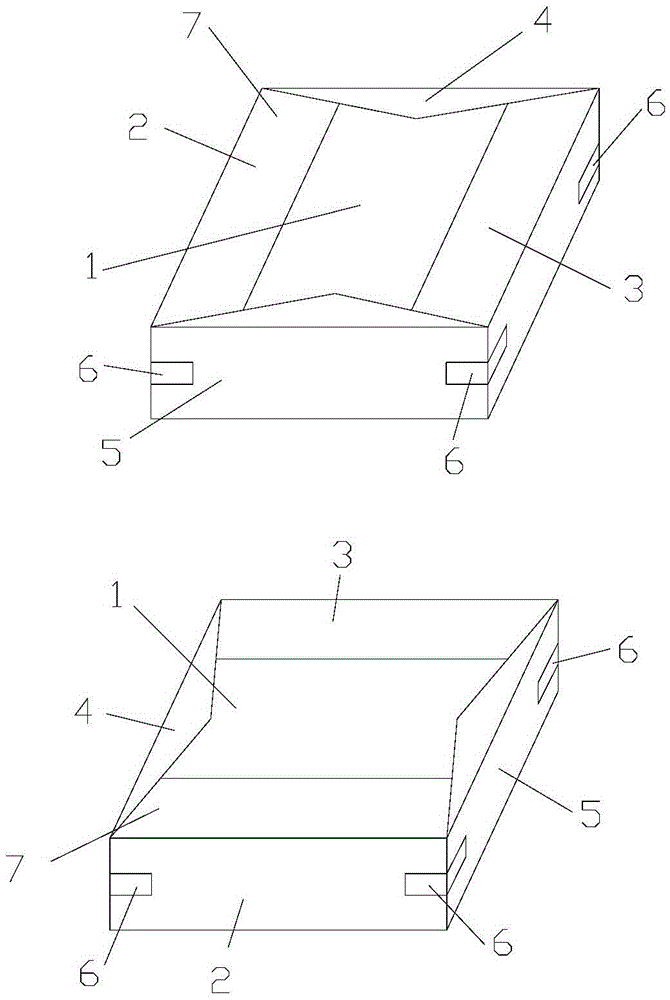

[0063] The above-mentioned wooden tire includes a plurality of wooden blanks stacked up and down in dislocation, and each layer of wooden blanks adopts a split splicing design, and its structure is the same as that of the wooden blanks in Example 1, which will not be repeated here. The difference is that each layer of wooden blanks and...

Embodiment 3

[0075] A method for making lacquer-sand inkstone, comprising six major steps of tire making, painting, rough cloth, dusting, dusting, and modification, and the specific operation steps are as follows:

[0076] ① Tire making: Use light, dry, stable wood, and fine-structured ginkgo wood as raw material, then cut the ginkgo wood into a wooden billet of appropriate size, and use a carving knife on the wooden billet according to the designed lacquer sand inkstone pattern Carry out digging, and finally use wood sandpaper to smooth the chisel marks on the wood billet, and sand the surface of the wood billet to make a wooden tire.

[0077] The above-mentioned wooden tire includes a plurality of wooden blanks stacked up and down in dislocation, and each layer of wooden blanks adopts a split splicing design, and its structure is the same as that of the wooden blanks in Example 1, which will not be repeated here. The difference is that each layer of wooden blanks and adjacent wooden blan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com