Ginkgolide B quick release pellet and preparation method thereof

A ginkgolide, quick-release technology, applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, allergic diseases, etc., can solve the problems of weak improvement of absorption effect, increase of drug particle size, low efficiency, etc. Achieve the effect of improving solubility and dissolution speed, improving absorption efficiency, and ensuring active structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of embodiment 1 nanosuspension

[0048] According to each prescription of Table 1, the stabilizer of prescription quantity is taken and dissolved in prescription quantity purified water to obtain stabilizer solution, and the ginkgolide B ethanol solution of prescription quantity is added in this solution, and ginkgolide B is mixed with stable The agent solution is fully mixed to obtain a coarse suspension, and then the coarse suspension is added to the nano grinder, and 380-450 g of zirconia beads with a diameter of 0.4 μm are added, and the grinding frequency is set to 3500 rpm, and the grinding is performed for a certain period of time. The time is shown in Table 2, and the ginkgolide B nanosuspension was prepared.

[0049] Table 1: Composition of different prescriptions

[0050]

[0051]

[0052] Table 2: Grinding time of different formulations and average particle size of the suspension after grinding

[0053] prescription number

...

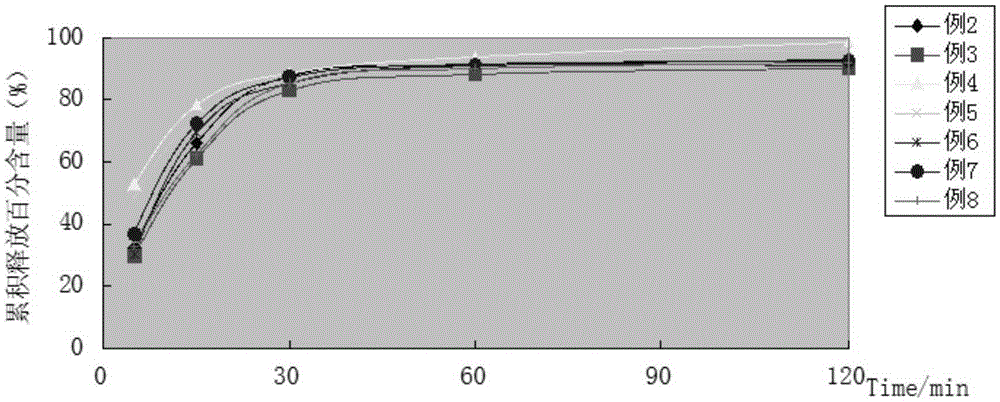

Embodiment 2

[0064] The preparation of embodiment 2 ginkgolide B quick-release pellets

[0065] Curing process prescription:

[0066]

[0067]

[0068] Get recipe quantity mannitol, sodium lauryl sulfate and be dissolved in appropriate amount of water and prepare curing stabilizer solution, get the nano-suspension 200g of ginkgolide B prepared by prescription 1 (the average particle diameter of ginkgolide B in the suspension is between 100 ~500nm range), the two are mixed evenly under the action of magnetic stirring, take the prescribed amount of microcrystalline cellulose pellets and place them in the fluidized bed, open the fluidized bed and set the process parameters (inlet air temperature 36°C; outlet air temperature 33°C ; Air volume 90m 3 / h; liquid supply pump speed 8-15rpm; atomization pressure 0.05-0.1mpa); secondly, turn on the liquid supply pump, and spray the drug nano-suspension onto the surface of the blank pellet core continuously. The latter stage can be accelerated...

Embodiment 3

[0070] The preparation of embodiment 3 ginkgolide B quick-release pellets

[0071] Curing process prescription:

[0072]

[0073] Get prescription quantity mannitol, sodium lauryl sulfate and be dissolved in appropriate amount of water and prepare solidification stabilizer solution, get the nano-suspension 200g of ginkgolide B prepared by prescription 2 (the average particle diameter of ginkgolide B in the suspension is between 100 ~500nm range), the two are mixed evenly under the action of magnetic stirring, take the prescribed amount of microcrystalline cellulose pellets and place them in the fluidized bed, open the fluidized bed and set the process parameters (inlet air temperature 36°C; outlet air temperature 33°C ; Air volume 110m 3 / h; liquid supply pump speed 8-15rpm; atomization pressure 0.05-0.1mpa); secondly, turn on the liquid supply pump, and spray the drug nano-suspension onto the surface of the blank pellet core continuously. The latter stage can be accelera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com