Spiral mixer for integrated injection of SCR catalyst

A technology of SCR catalyst and mixer, applied in machine/engine, exhaust gas treatment, mechanical equipment, etc., can solve the problems of difficult layout of integrated nozzles, insufficient space for urea atomization, change of urea injection performance, etc., to improve the mixing effect , the effect of reducing the risk of urea crystallization and increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

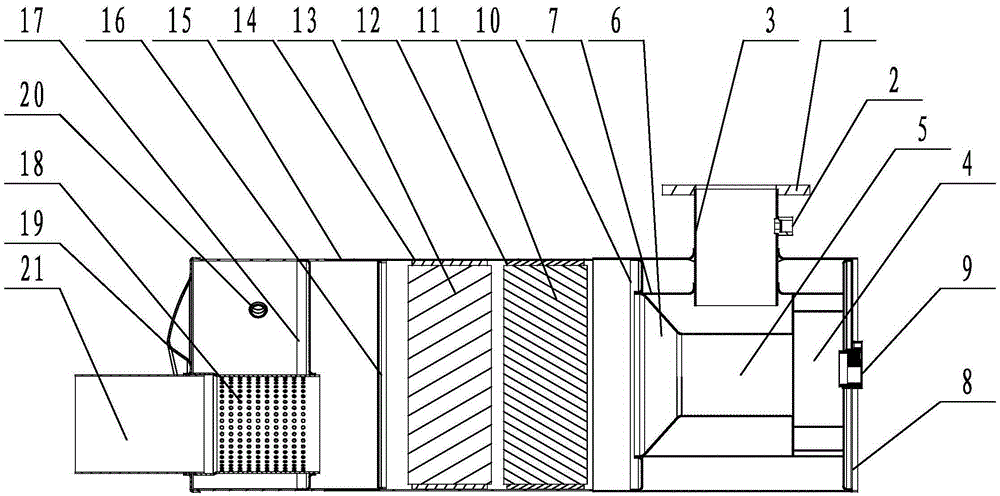

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

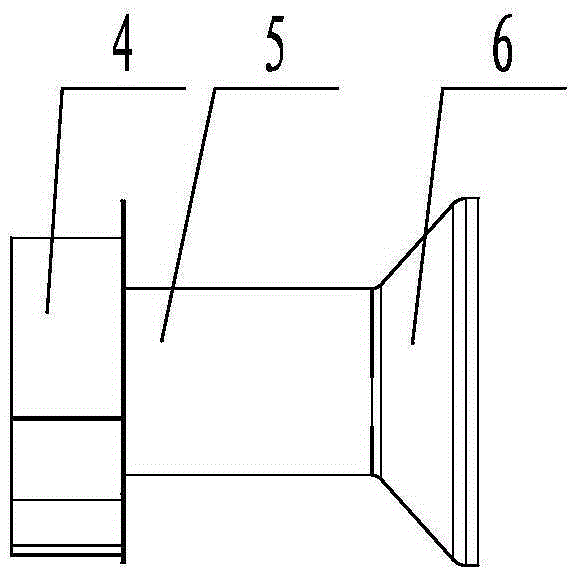

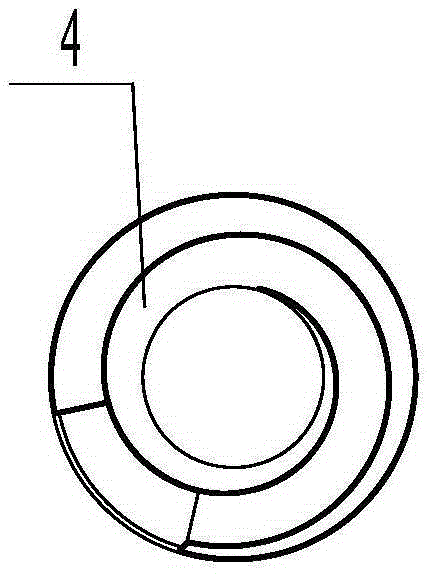

[0015] Figure 1~4 Including air inlet flange 1, temperature sensor 2, air inlet pipe 3, mixer 4, air inlet 4-1, windshield 4-2, mixing pipe 5, cone pipe 6, heat preservation cylinder 7, front end cover 8, Urea nozzle base 9, first partition 10, first SCR carrier 11, first gasket 12, second SCR carrier 13, second gasket 14, cylinder 15, second partition 16, third partition 17 , Muffler pipe 18, rear end cover 19, nitrogen oxide sensor 20, air outlet pipe 21, etc.

[0016] Such as Figure 1~4 As shown, the present invention is a spiral mixer for SCR catalytic converter integrated injection, including a cylinder 15, the two ends of the cylinder 15 are respectively provided with a front end cover 8 and a rear end cover 19, and the inner cavity of the cylinder 15 is provided with a second An SCR carrier 11, a second SCR carrier 13, an air inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com