Three-phase split phase-shifting transformer for high-voltage frequency conversion and its use

A phase-shifting transformer and high-voltage frequency conversion technology, which is applied in the direction of transformers, transformers/inductor coils/windings/connections, inductors, etc., can solve the problems of grid harmonic pollution, low power factor and efficiency, and low output frequency. Solve harmonic pollution, reduce harmonic loss, and reduce the effect of grid-side current harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Below in conjunction with accompanying drawing and specific example for further detailed description:

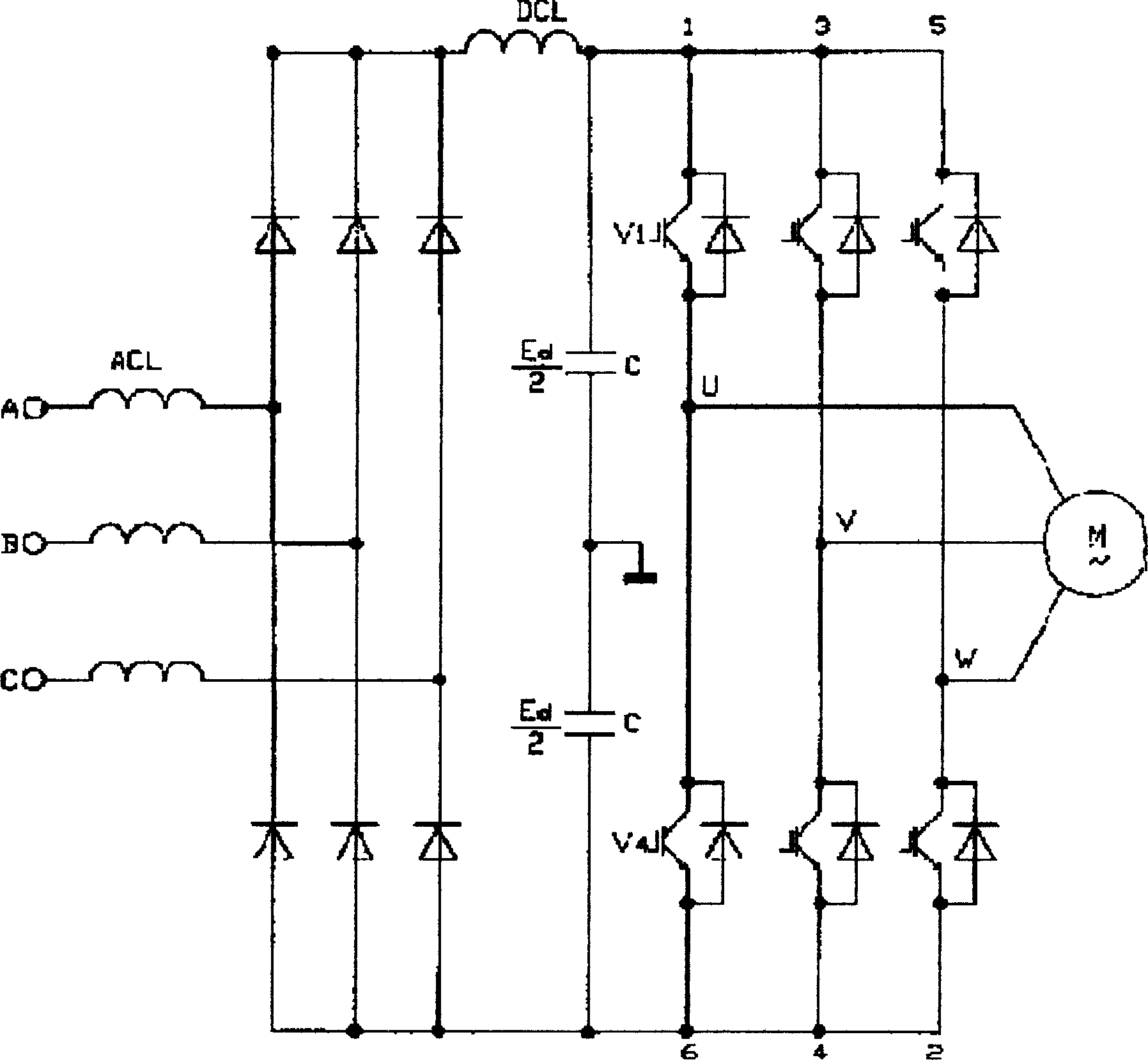

[0065] Figure 9 That is, N power units connected in series using the transformer of the present invention are multi-level PWM frequency converters. Its power unit is a common, mature, reliable, low-voltage single-phase PWM inverter. Relying on an integrated, specially designed multi-winding transformer T with independent valve sides and a certain phase shift, if this low-voltage inverter is reorganized—the units are multiplexed and stacked in series, 3N identical Low-voltage single-phase inverters have been successfully applied to high-voltage and high-power inverters. It ideally solves the problem of harmonic interference which is difficult to avoid with general 6 or 12 pulses.

[0066] attached Figure 10 One of the power units, the AC-DC-AC voltage source PWM inverter with single-phase output, is drawn. Diodes form a three-phase bridge rectifier circuit, powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com