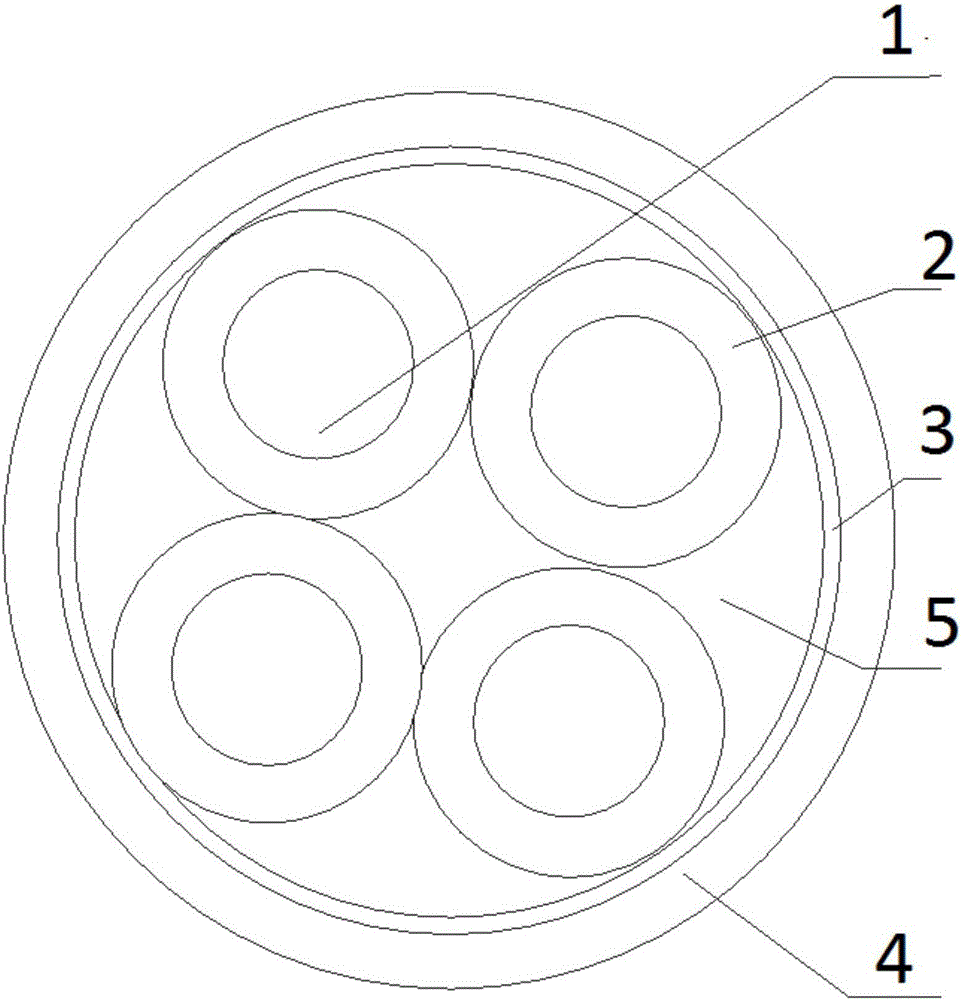

A high radiation dose resistant cable and its manufacturing method

A manufacturing method and radiation dose technology, applied in the direction of cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of reducing cable service life, prone to aging, cable failure, etc., to improve protection and increase insulation radiation resistance performance , enhance the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0063] When welding a copper strip with a thickness of 0.4mm, the welding base value current is 180A, and the argon gas flow rate is 14.0L / min;

[0064] When welding a copper strip with a thickness of 0.5mm, the welding base value current is 210A, and the argon gas flow rate is 14.0L / min;

[0065] When welding a copper strip with a thickness of 0.6mm, the welding base value current is 250A, and the argon gas flow rate is 14.0L / min.

example 2

[0067] When welding a copper strip with a thickness of 0.4mm, the welding base value current is 200A, and the argon gas flow rate is 15.0L / min;

[0068] When welding copper strip with a thickness of 0.5mm, the welding base value current is 220A, and the argon gas flow rate is 15.0L / min;

[0069] When welding a copper strip with a thickness of 0.6mm, the welding base value current is 260A, and the argon gas flow rate is 15.0L / min.

example 3

[0071] When welding a copper strip with a thickness of 0.4mm, the welding base value current is 210A, and the argon gas flow rate is 16.0L / min;

[0072] When welding a copper strip with a thickness of 0.5mm, the welding base current is 230A, and the argon gas flow rate is 16.0L / min;

[0073] When welding copper strips with a thickness of 0.6mm, the welding base value current is 280A, and the argon gas flow rate is 16.0L / min.

[0074] After practical comparison, the cable obtained by the process of Example 2 has a pass rate of more than 99.8%, especially the matching of argon flow and voltage and current values, so that the welding position is fully protected, and the temperature reduction rate can make the cooling and welding position temperature to achieve the best match.

[0075] The cable obtained by the process of Example 1 has a pass rate of more than 99.4%. Among them, the pass rate corresponding to the process parameters when welding a copper strip with a thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com