Black matte polyimide thin film and preparation method thereof

A matte polyimide and film preparation technology, applied in the field of black matt polyimide film and its preparation, can solve the problems of low gloss, low light transmittance and high process requirements, and achieve low light transmittance and gloss, increase mechanical properties, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

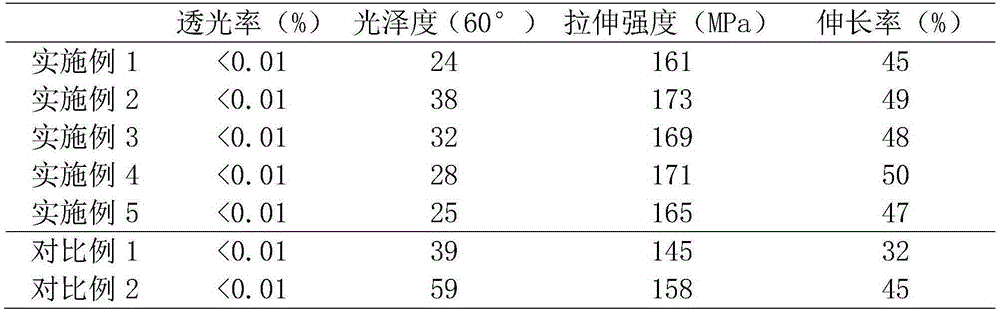

Examples

Embodiment 1

[0025] 1) Preparation of black slurry: Weigh 1000g of N,N-dimethylacetamide solvent, add 20g of γ-aminopropyltriethoxysilane, stir for 15min, add 150g of carbon black, ultrasonically pre-disperse for 30min, Homogenize for 30 minutes by a high-pressure homogenizer to obtain a stable black slurry;

[0026] 2) Preparation of inorganic filler dispersion: Add 40g of silicon dioxide (10um) and 5g of talc powder (5um) into 1000g of N,N-dimethylacetamide solvent, shear and disperse for 1h, and ultrasonically disperse for 2h to obtain a stable Inorganic filler dispersion;

[0027] 3) Preparation of black matt polyimide film:

[0028] At room temperature, weigh 1000g of N,N-dimethylacetamide solvent, add 119.65g of 4,4'-diaminodiphenyl ether, dissolve and add pyromellitic dianhydride in the same molar ratio, and stir After reacting for 4 hours, add 40 g of black slurry and 500 g of inorganic filler dispersion, mix and stir for 8 hours, and form a film through defoaming, casting, biaxi...

Embodiment 2

[0030] 1) Preparation of black slurry: Weigh 1000g of N,N-dimethylacetamide solvent, add 0.5g of sodium dodecylbenzenesulfonate, stir for 15min, add 20g of carbon black, pre-disperse by ultrasonic for 30min, and then Homogenize for 15 minutes by a high-pressure homogenizer to obtain a stable black slurry;

[0031] 2) Preparation of inorganic filler dispersion: Add 150g of titanium dioxide (6um) and 80g of talc powder (0.1um) into 1000g of N,N-dimethylacetamide solvent, shear and disperse for 3 hours, and ultrasonically disperse for 2 hours to obtain a stable inorganic filler filler dispersion;

[0032] 3) Preparation of black matt polyimide film:

[0033] At room temperature, weigh 1000g of N,N-dimethylacetamide solvent, add 101.24g of 3,4'-diaminodiphenyl ether, dissolve and add 3,3',4,4 '-Biphenyltetraacid dianhydride, after stirring and reacting for 4 hours, add 400g of black slurry and 50g of inorganic filler dispersion, mix and stir for 8 hours, and form a film through ...

Embodiment 3

[0035] 1) Preparation of black slurry: Weigh 900g of N,N-dimethylacetamide solvent, add 20g of γ-aminopropyltriethoxysilane, stir for 15min, add 100g of carbon black, ultrasonically pre-disperse for 30min, Homogenize for 15 minutes by a high-pressure homogenizer to obtain a stable black slurry;

[0036] 2) Preparation of inorganic filler dispersion: Add 100g of silicon dioxide (2um) and 20g of talc powder (1um) into 1000g of N,N-dimethylacetamide solvent, shear and disperse for 3 hours, and ultrasonically disperse for 2 hours to obtain a stable Inorganic filler dispersion;

[0037] 3) Preparation of black matt polyimide film:

[0038] At room temperature, weigh 1000g of N,N-dimethylacetamide solvent, add 119.65g of 4,4'-diaminodiphenyl ether, dissolve and add pyromellitic dianhydride with equal substance ratio, stir After reacting for 4 hours, add 150 g of black slurry and 150 g of inorganic filler dispersion, mix and stir for 8 hours, and then form a film through defoaming,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com