High performance short glass fiber enhanced polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, which is applied in the field of high-performance short glass fiber reinforced polypropylene composite material and its preparation, can solve the problems of product quality fluctuation, glass fiber fracture damage, long screw stroke, etc., to ensure the retention length and improve the Effects of impact strength and fluidity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

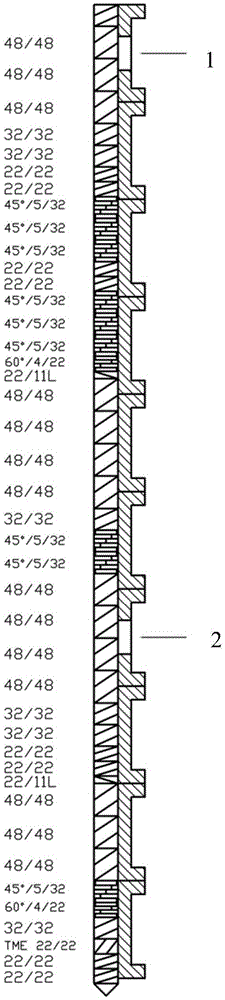

Image

Examples

Embodiment 1~5

[0060] The preparation of modified polypropylene includes: dissolving dicumyl peroxide (DCP) and silane coupling agent KH-550 with acetone. A small amount of acetone is used to dissolve dicumyl peroxide (DCP) and silane coupling. Coupling agent is sufficient, and it is evenly mixed with polypropylene. The mass ratio of dicumyl peroxide, silane coupling agent KH-550 and polypropylene is 1:3:100, and then extruded by twin screw extruder after drying. , Pelletizing to obtain modified polypropylene;

[0061] The preparation of the modified chopped glass fiber includes: putting the chopped glass fiber into the aqueous solution of the silane coupling agent KH-550 (the mass percentage of the silane coupling agent is 30%), then take it out, and bake it at 80℃ for 1h. , Remove part of the water, and then increase the temperature to 140°C for 45 minutes to obtain the coupling agent grafted polypropylene, which makes the coupling agent and the glass fiber form a firm bond. Finally, the coup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Notched izod impact | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com