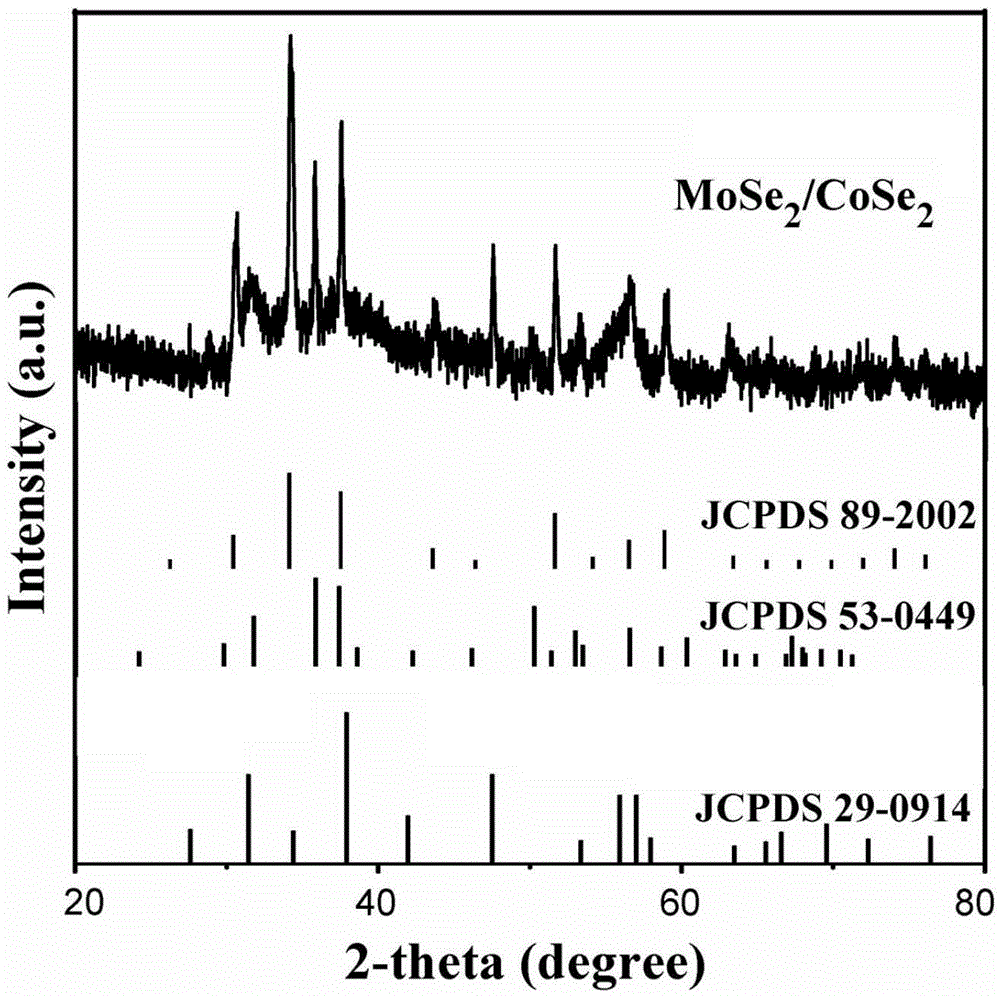

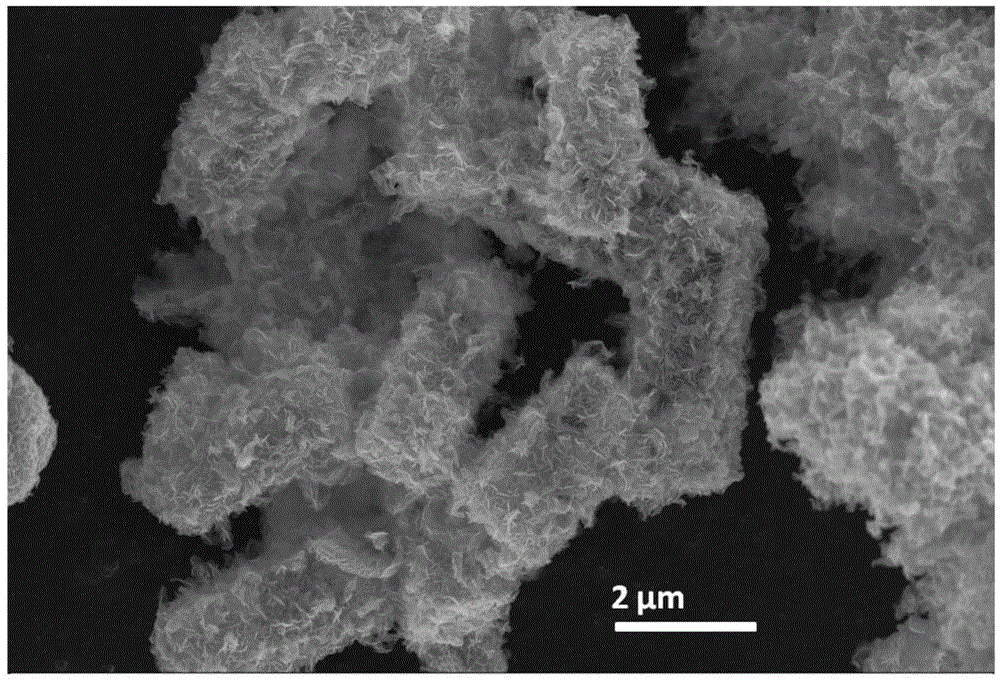

Preparation method of molybdenum diselenide/cobalt diselenide nanocomposite

A nanocomposite material, a technology of cobalt diselenide, which is applied in the field of preparation of molybdenum diselenide/cobalt diselenide nanocomposite materials, can solve problems such as complicated operation, achieve simple raw materials, good electrocatalytic activity, and simple process equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of molybdenum diselenide / cobalt diselenide nanocomposite material, comprising the following steps:

[0031] Step 1: Add molybdate, cobalt salt and selenium dioxide into deionized water under the stirring condition of 200-500rpm, stir and mix evenly to obtain a mixed liquid; wherein, the concentration of molybdate is 0.002-0.05mol / L , the concentration of cobalt salt is 0.01~0.1mol / L, the concentration of selenium dioxide is 0.02~0.5mol / L;

[0032] Step 2: Under the stirring condition of 200~500rpm, add a complexing agent to the mixed solution obtained in step 1, and continue to stir until an emulsion is obtained; wherein, the volume ratio of the added complexing agent to the deionized water described in step 1 is 0.5~2;

[0033] Step 3: Transfer the emulsion obtained in step 2 to a stainless steel autoclave lined with polytetrafluoroethylene, place the autoclave in a heating furnace, and perform a hydrothermal reaction at a temperature of 160 to 24...

Embodiment 1

[0039] A preparation method of molybdenum diselenide / cobalt diselenide nanocomposite material, comprising the following steps:

[0040] Step 1: Dissolve 0.17mmol ammonium molybdate, 1.2mmol cobalt acetate and 4.8mmol selenium dioxide powder in 20mL deionized water under the stirring condition of 200rpm, and continue stirring until a uniform mixed solution A is obtained;

[0041] Step 2: Under the stirring condition of 200rpm, add 20mL of ethylenediamine as a complexing agent to the mixed solution A obtained in step 1, and keep stirring until the emulsion B is obtained;

[0042] Step 3: Transfer the emulsion B obtained in step 2 to a 100mL stainless steel autoclave lined with polytetrafluoroethylene, place the autoclave in a heating furnace, react at 180°C for 18h, and then cool naturally to room temperature, and transfer the solution C after the reaction in the autoclave to the beaker;

[0043] Step 4: The reacted solution C obtained in step 3 was subjected to high-speed cent...

Embodiment 2

[0048] A preparation method of molybdenum diselenide / cobalt diselenide nanocomposite material, comprising the following steps:

[0049] Step 1: Dissolve 0.26mmol ammonium molybdate, 1.2mmol cobalt acetate and 4.8mmol selenium dioxide powder in 20mL deionized water under the stirring condition of 300rpm, and continue stirring until a uniform mixed solution A is obtained;

[0050] Step 2: Under the stirring condition of 300rpm, add 20mL of ethylenediamine as a complexing agent to the mixed solution A obtained in step 1, and keep stirring until the emulsion B is obtained;

[0051] Step 3: Transfer the emulsion B obtained in step 2 to a 100mL stainless steel autoclave lined with polytetrafluoroethylene, place the autoclave in a heating furnace, react at 220°C for 20h, and then cool naturally to room temperature, and transfer the solution C after the reaction in the autoclave to the beaker;

[0052] Step 4: The reacted solution C obtained in step 3 was subjected to high-speed cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com