Solid oxide fuel cell, manufacturing method therefor, fuel-cell stack, and solid oxide fuel-cell device

A fuel cell unit, solid oxide technology, applied in fuel cells, battery electrodes, electrical components, etc., can solve the problems of low initial power generation performance of solid oxide fuel cell units and high resistance value of the anti-diffusion layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

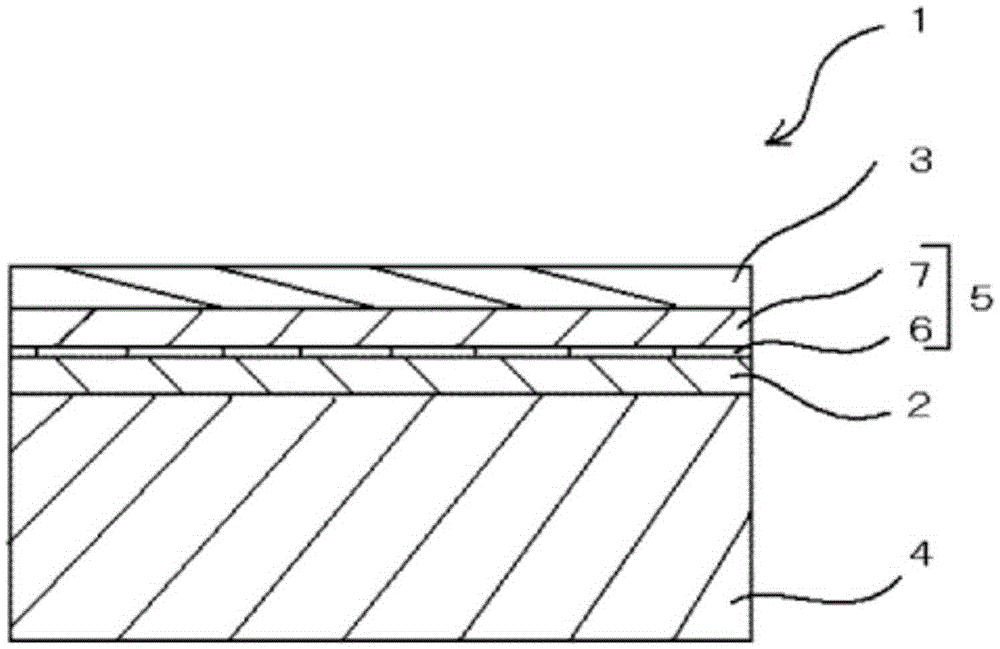

[0116] (1) Preparation of green sheet for solid electrolyte layer

[0117] For the specific surface area measured by BET method is 5 ~ 7m 2 / g of YSZ powder, add butyral resin, dioctyl phthalate (DOP) as a plasticizer, a dispersant, and a mixed solvent of toluene and ethanol, and mix with a ball mill to prepare a slurry. From the obtained slurry, a green sheet for a solid electrolyte layer having a thickness of 10 μm was obtained by using a doctor blade method.

[0118] (2) Preparation of green sheet for fuel electrode layer

[0119] For the specific surface area measured by BET method is 3 ~ 4m 2 / g of NiO powder is weighed so that the weight converted to Ni is 55 parts by mass, and the specific surface area measured by the BET method is 5 to 7 m 2 45 parts by mass of powder of YSZ / g were mixed to obtain a mixed powder. To this mixed powder, a butyral resin, DOP as a plasticizer, a dispersant, and a mixed solvent of toluene and ethanol were added, and mixed with a ball mi...

example 2

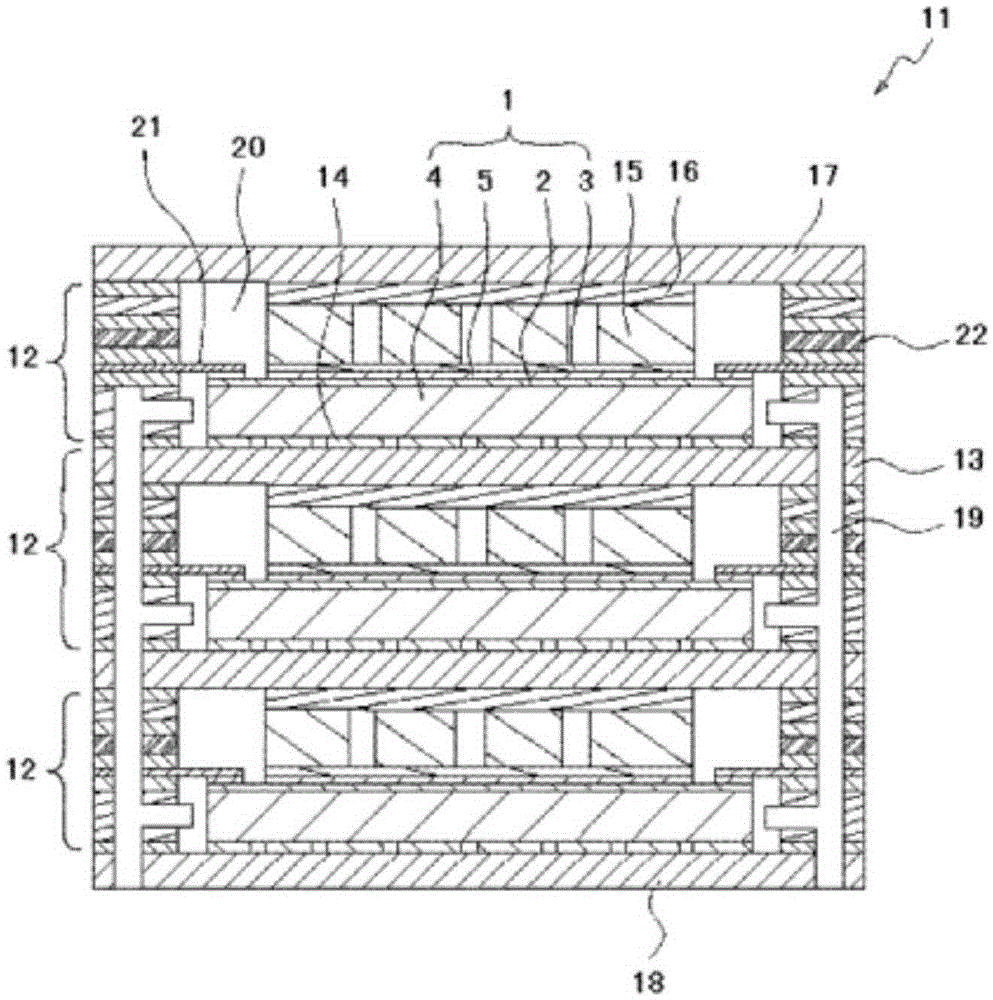

[0137] In the process of (4) preparation, printing and firing of the slurry for forming the intermediate layer, the firing is carried out at 1200° C., so that the thickness of the intermediate layer is 3 μm, and the thickness of the initial anti-diffusion layer is 300 nm. In addition Other than that, the experiment was carried out in the same manner as in Example 1, and the thickness of the element diffusion prevention layer, the average particle diameter of the element diffusion prevention layer, and the Sr coverage were measured, and the deterioration rate was calculated. The results are shown in Table 1 and Table 2 below.

example 3

[0139] In the process of (4) preparation, printing and firing of the slurry for forming the intermediate layer, the firing is carried out at 1250° C., so that the thickness of the intermediate layer is 3 μm, and the thickness of the initial anti-diffusion layer is 400 nm. In addition Other than that, the experiment was carried out in the same manner as in Example 1, and the thickness of the element diffusion prevention layer, the average particle diameter of the element diffusion prevention layer, and the Sr coverage were measured, and the deterioration rate was calculated. The results are shown in Table 1 and Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com