Substrate for photoelectric conversion elements

A technology of photoelectric conversion elements and substrates, which is applied in the fields of electrical components, photovoltaic power generation, and electric solid-state devices, and can solve the problems of reducing manufacturing costs, instability, and high prices of organic thin-film solar cells, and achieves excellent power generation characteristics, easy operation, and reduced cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

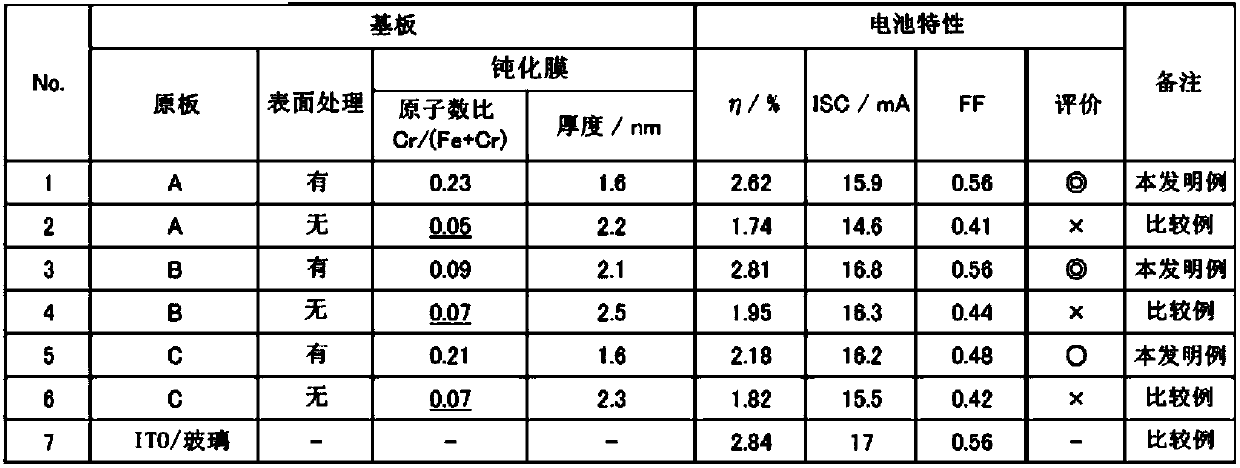

[0062] Next, the present invention will be specifically described based on examples. The following examples show suitable examples of the present invention, and the present invention is not limited to these examples. The embodiments of the present invention can be appropriately changed within the range consistent with the gist of the present invention, and these are included in the technical scope of the present invention.

[0063] A substrate for a photoelectric conversion element made of a stainless steel plate and an organic thin-film solar cell using the substrate for a photoelectric conversion element were produced, and their characteristics were evaluated. In addition, for comparison, an organic thin-film solar cell using a conventional glass substrate was fabricated and evaluated together. Hereinafter, the production procedure and evaluation method of the substrate for photoelectric conversion elements and the organic thin-film solar cell will be described.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com