Fuel cell system

A fuel cell system and fuel cell stack technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve problems such as the reduction of the power generation performance of the fuel cell stack, and achieve the purpose of suppressing the generation of dew condensation water and the reduction of power generation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

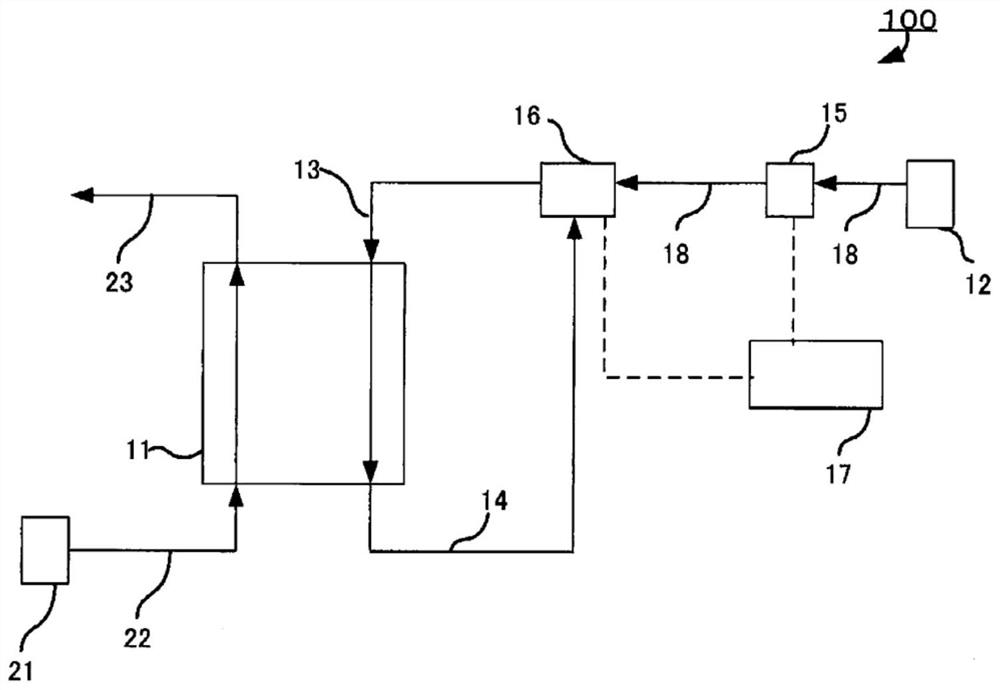

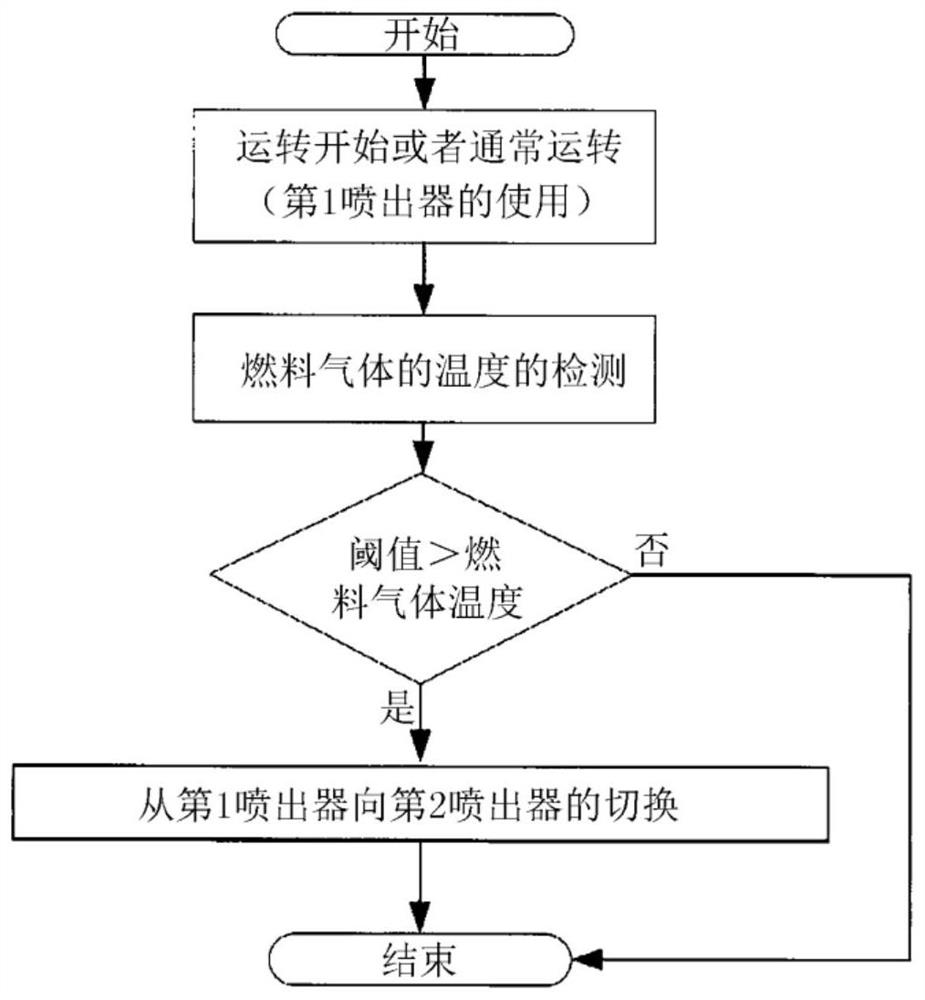

[0026] In the present disclosure, there is provided a fuel cell system characterized in that the fuel cell system includes: a fuel cell stack; an injector assembly; a fuel gas supply section for supplying fuel gas to the injector assembly; A channel for recovering the fuel off-gas discharged from the fuel cell stack, and returning it to the above-mentioned ejector collection part as circulating gas; a mixed gas supply flow path for connecting the above-mentioned ejector collection part to the above-mentioned fuel cell stack, so that A mixed gas including the fuel gas and the circulating gas is supplied from the injector assembly to each fuel electrode of the fuel cell stack; a temperature detection unit detects the temperature of the fuel gas; and a control unit, the injector The collection part has at least two injectors in parallel, wherein the first injector supplies the first mixed gas to each fuel electrode of the fuel cell stack, and the second injector supplies the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com