Core material for cushion, and cushion

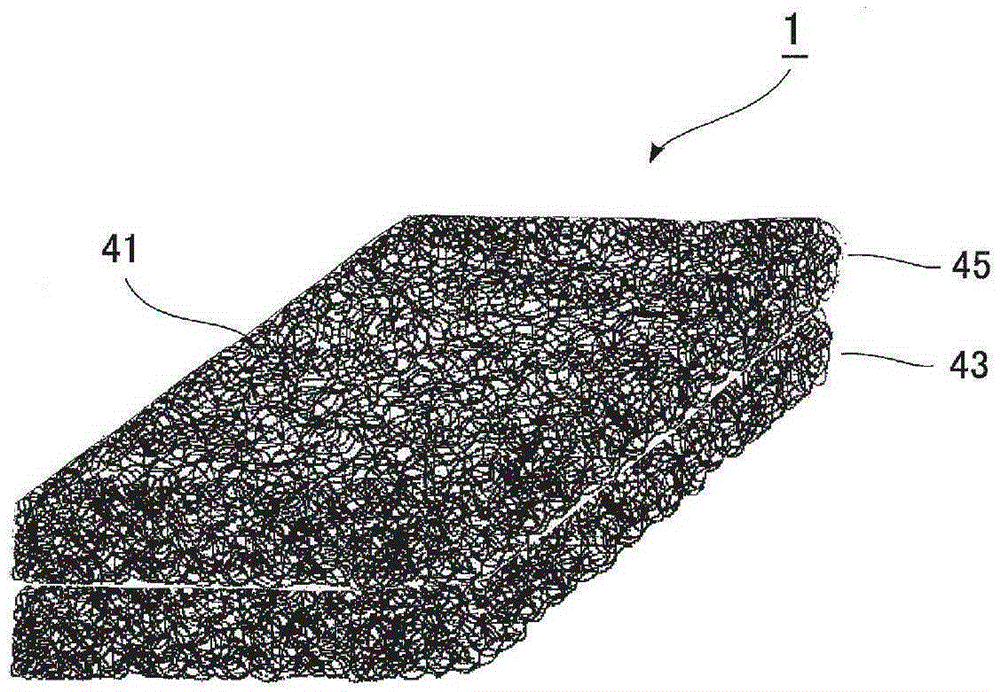

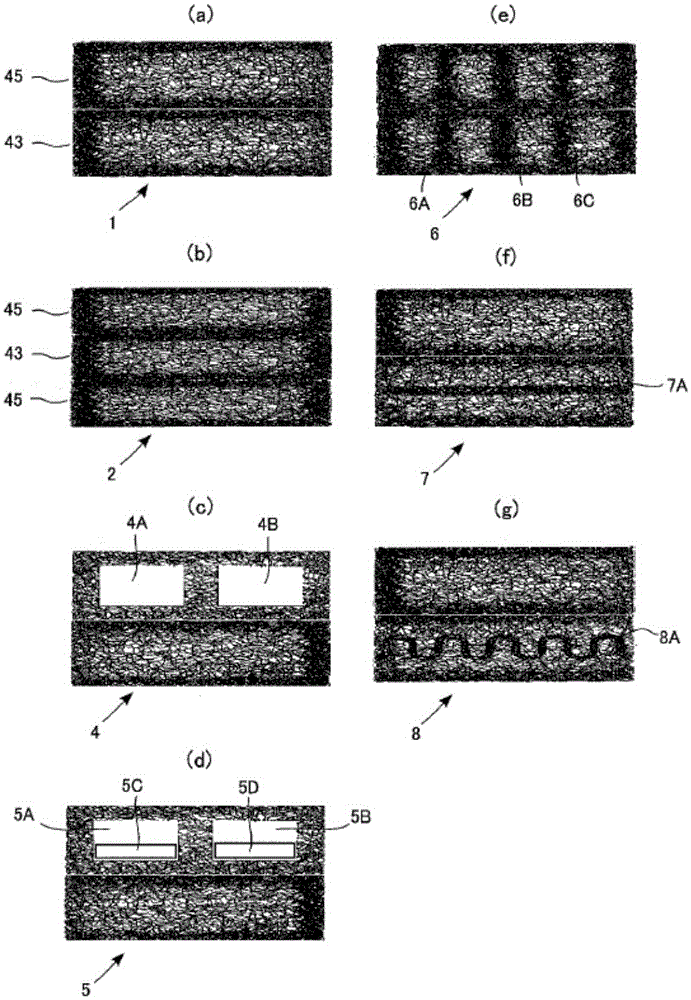

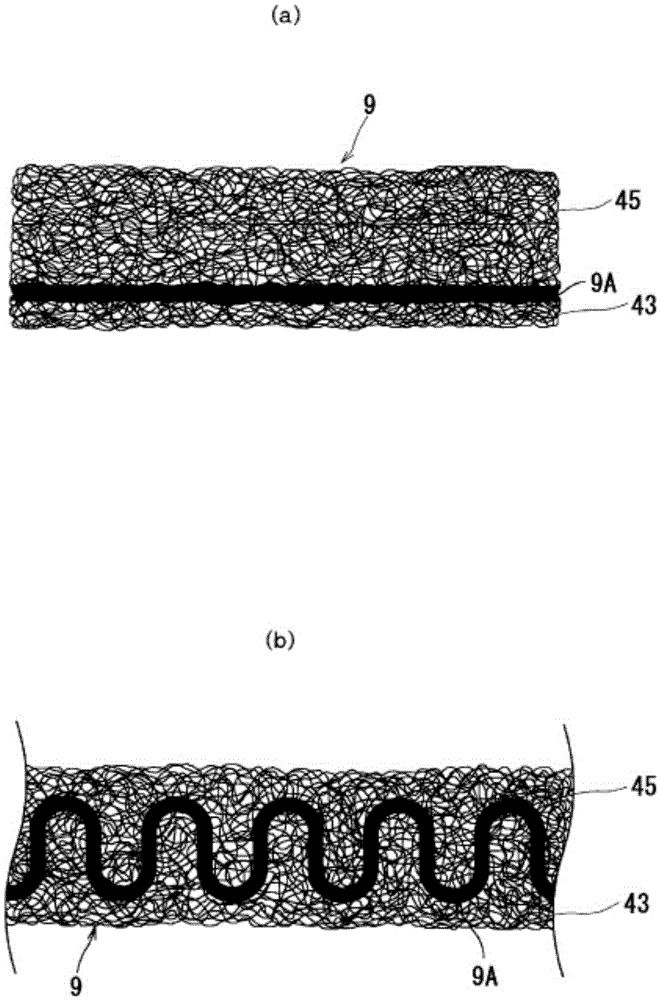

A core material and cushion technology, applied in the field of cushions and medical care cushions, achieves the effect of being easy to handle, meeting the diverse needs of elastic properties, and being light in weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0221] Example 1 is an example of layer 43, and the conditions used are as follows: the screw diameter of the extruder is 65 mm; the temperature of the die is 205 degrees Celsius; the die width is 890 mm and the thickness is 75 mm; the hole slope is 10 mm; The hole diameter is 1.6 mm; and the air gap (distance between the lower surface of the nozzle and the horizontal plane) is 67 mm. Hexane, hexene, and ethylene are used as main raw materials, and are polymerized by a known method using a metallocene compound as a catalyst. Melt viscosity (Pa) of the obtained ethylene / α-olefin copolymer: 1.05 at a shear rate of 24.3 per second, 1.12 at a shear rate of 60.8 per second, 1.15 at a shear rate of 121.6 per second, 1.18 at a shear rate of 243.2 per second, 1.23 at a shear rate of 608.0 per second, and 1.26 at a shear rate of 1216 per second; the MFR is 12 grams / 10 minutes, and the density is 0.9 grams per cubic centimeter, The filaments of ethylene / α-olefin copolymer were ejected ...

Embodiment 2

[0223] Example 2 is another example of layer 43, the conditions used are as follows: the screw diameter of the extruder is 40 mm; the die temperature is 190 degrees Celsius; the die has a width of 500 mm and a thickness of 25 mm; the hole slope is 10 mm ; the diameter of the nozzle hole is 1.6 mm; and the air gap (the distance between the lower surface of the nozzle and the horizontal plane) is 38 mm. Filaments of ethylene / α-olefin copolymer (produced from the same raw material as in Example 1) and polyethylene were ejected downward from the nozzle at a melt temperature of 160°C at an extrusion rate of 13 kg / h. The lower end of the chute is located 36mm below the nozzle and submerged in water. A pair of 55 cm wide stainless steel traction conveyor belts are parallel to each other across the 23 mm opening and positioned partially above the water. The filaments ejected from the molten state are solidified in the chute under the water heating chute at 36 degrees Celsius. The fi...

Embodiment 3

[0225] Example 3 is another example of layer 45, using the following conditions: extruder screw diameter 65 mm; die temperature 217 degrees Celsius; die width 900 mm and thickness 30 mm; orifice slope 10 mm ; the diameter of the nozzle hole is 1 mm; and the air gap (the distance between the lower surface of the nozzle and the horizontal plane) is 69 mm. Melt viscosity (Pa) of thermoplastic elastomer (registered trademark Hytrel): 1.26 at a shear rate of 60.8 per second, 1.28 at a shear rate of 121.6 per second, 1.15 at a shear rate of 121.6 per second, and 1.15 at a shear rate of 121.6 per second. It is 1.30 at a shear rate of 243.2 seconds, 1.30 at a shear rate of 608.0 per second, and 1.33 at a shear rate of 1216 per second; MFR is 12 grams / 10 minutes, and the density is 1.08 grams per cubic centimeter, thermoplastic Elastomer filaments were ejected downward from the nozzle at an extrusion rate of 27.5 kg / hr and a melt temperature of 195 degrees Celsius, the lower end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase distortion | aaaaa | aaaaa |

| apparent density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com