Method for preparing silver nanowire-graphene composite aerogel

A graphene composite, silver nanowire technology, applied in the field of catalyst preparation, can solve problems such as unsatisfactory catalytic results, and achieve the effects of adjustable shape, super large porosity and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

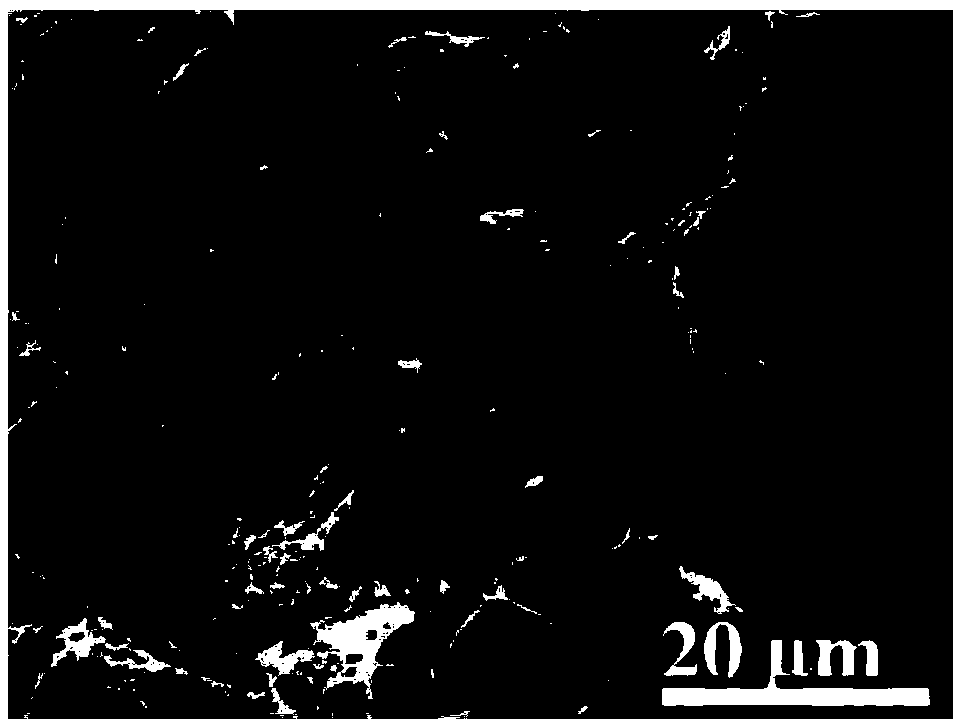

[0039] 200 mg of graphene oxide was dissolved in 100 mL of deionized water, and ultrasonically oscillated for 2 hours to prepare a graphene oxide aqueous solution with a mass concentration of 2 mg / ml. Take 15ml of graphene oxide aqueous solution and put it into a beaker, then add 90mg of reducing agent, mix evenly, transfer the mixed solution into a closed container, and keep it warm at 90°C for 20h to prepare graphene hydrogel. After the reaction, rinse the graphene hydrogel with deionized water, adjust the pH to 6.5, freeze the above product in a refrigerator at -75°C for 4 hours, and then dry the product in a freeze dryer for 12 hours to prepare the sample graphene Airgel A. The reducing agent is sodium sulfite.

Embodiment 2

[0041] 200 mg of graphene oxide was dissolved in 100 mL of deionized water, and ultrasonically oscillated for 2 hours to prepare a graphene oxide aqueous solution with a mass concentration of 2 mg / ml. Take 15ml of graphene oxide aqueous solution and add it to a beaker, then add 1.5ml of Ag nanowire aqueous solution (mass concentration is 10mg / ml), then add 90mg of reducing agent, after mixing evenly, transfer the mixed solution into a closed container, and keep it warm at 90°C 20h, the silver nanowire / graphene hydrogel was prepared. After the reaction, rinse the silver nanowire / graphene hydrogel with deionized water, adjust the pH to 6.5, freeze the above product in a -75°C refrigerator for 4 hours, and then dry the product in a freeze dryer for 12 hours to prepare Obtain sample silver nanowire / graphene airgel B.

[0042] In this embodiment, the width of the silver nanowires is 20-80 nm. The reducing agent is sodium sulfite.

Embodiment 3

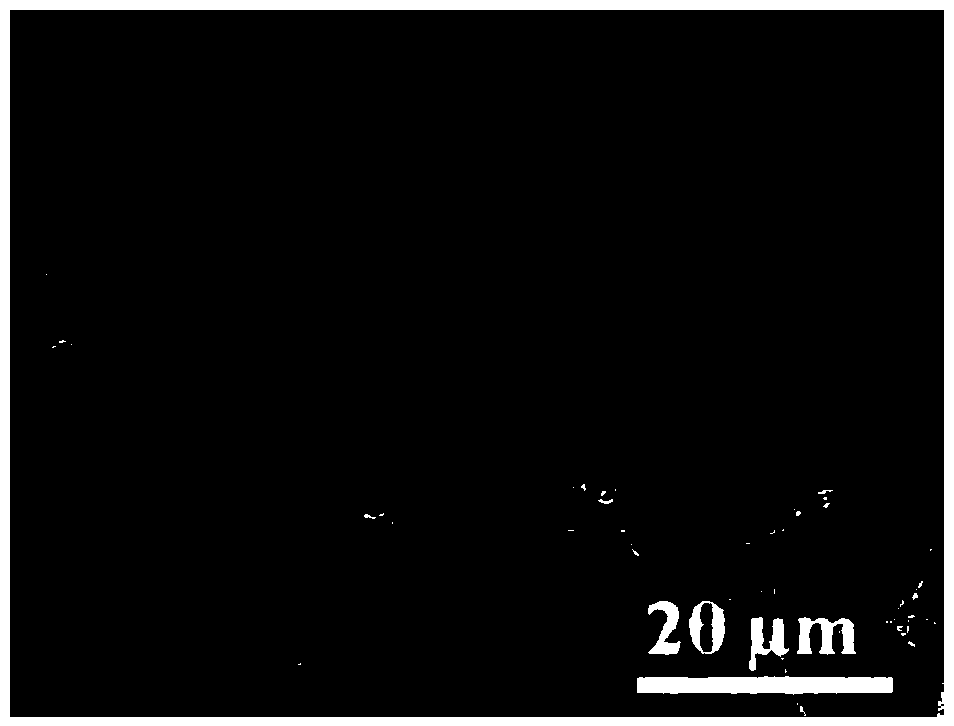

[0044]200 mg of graphene oxide was dissolved in 100 mL of deionized water, and ultrasonically oscillated for 2 hours to prepare a graphene oxide aqueous solution with a mass concentration of 2 mg / ml. Take 15ml of graphene oxide aqueous solution and add it to a beaker, then add 3ml of Ag nanowire aqueous solution (mass concentration is 10mg / ml), then add 90mg of reducing agent, after mixing evenly, transfer the mixed solution into a closed container, and keep it warm at 90°C for 20h , to prepare silver nanowire / graphene hydrogels. After the reaction, rinse the silver nanowire / graphene hydrogel with deionized water, adjust the pH to 6.5, freeze the above product in a -75°C refrigerator for 4 hours, and then dry the product in a freeze dryer for 12 hours to prepare Obtain sample silver nanowire / graphene airgel C.

[0045] In this embodiment, the width of the silver nanowires is 20-80 nm. The reducing agent is sodium sulfide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com