A composite densifier fracturing fluid

A fracturing fluid and thickening agent technology, applied in the field of chemicals, can solve the problems of affecting the conductivity of propped fractures, hindering the production of formation fluids, affecting the productivity of oil and gas wells, etc. Excellent effect of joint performance, temperature resistance and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 950ml of water to the Wuyin mixer, add 5g of KCl and 1g of formaldehyde while stirring, weigh 1g of hydroxypropyl guar gum and 40g of modified starch, add them slowly to the water while stirring, and stir at high speed for 15min ; then add 1g sodium thiosulfate, 1g sodium carbonate and 1g cetyltrimethylammonium bromide; stir in a mixer for 10min to complete the preparation of the base liquid; take the above prepared base liquid 100ml, stir Add 0.3g of sodium tetraborate, continue to stir for 2 minutes, the base liquid and the crosslinking agent react completely to form a jelly, and complete the preparation of the jelly; add 0.3g of ammonium persulfate capsule breaker to the jelly under stirring, Maintain a constant temperature in a water bath at 50°C. After 2 hours, the jelly is completely broken and hydrated. The apparent viscosity of the base liquid measured by a six-speed rotational viscometer is 80mPa.s, and the pH is 10; the rheological properties of the jelly ...

Embodiment 2

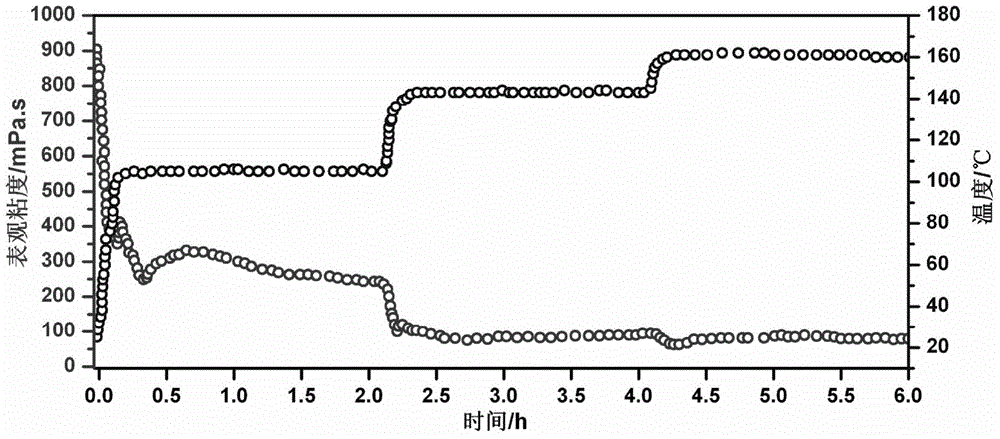

[0033] Add 934ml of water to the Wuyin mixer, add 20g of KCl and 3g of formaldehyde under stirring, weigh 2g of hydroxypropyl guar gum and 30g of modified starch, add them slowly to the water under stirring, and stir at high speed for 15min ; then add 5g sodium thiosulfate, 3g sodium carbonate and 3g dodecyltrimethylammonium bromide; stir in a mixer for 10min to complete the preparation of the base liquid; get the above prepared base liquid 100ml, stir Add 0.6g organoboron-zirconium crosslinking agent, continue to stir for 2 minutes, the base liquid and the crosslinking agent completely react to form a jelly, and complete the preparation of the jelly solution; add 0.6g ammonium persulfate capsules to the jelly under stirring state to break For the gel, keep a constant temperature in a water bath at 50°C. After 2 hours, the gel will be completely broken and hydrated. The apparent viscosity of the base liquid measured by a six-speed rotational viscometer is 55mPa.s, and the pH i...

Embodiment 3

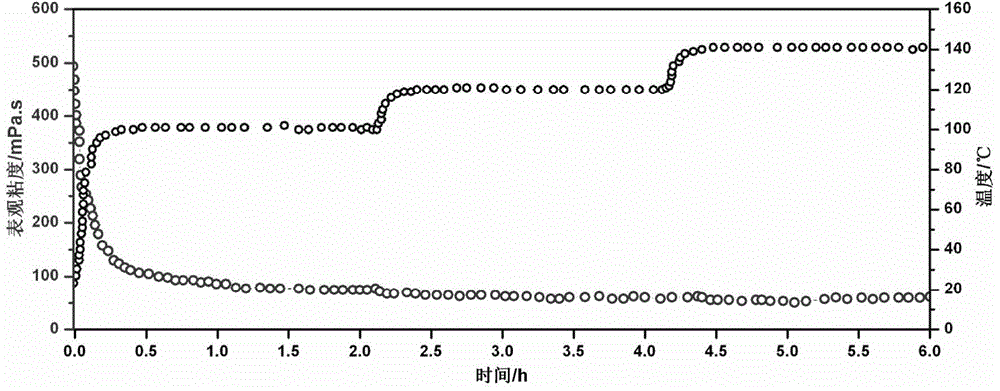

[0037] Add 930ml of water to the Wuyin mixer, add 20g of KCl and 3g of formaldehyde under stirring, weigh 3g of hydroxypropyl guar gum and 20g of modified starch, add them slowly to the water under stirring, and stir at high speed for 15min ; then add 3g sodium thiosulfate, 2g sodium carbonate and 2g cetyltrimethylammonium bromide; stir in a mixer for 10min to complete the preparation of the base liquid; get the above prepared base liquid 100ml, stir Add 1g of organoboron cross-linking agent, continue to stir for 2 minutes, the base liquid and the cross-linking agent completely react to form a jelly, and complete the preparation of the jelly solution; add 1g of ammonium persulfate capsule breaker to the jelly under stirring, Maintain a constant temperature in a water bath at 50°C. After 2 hours, the jelly is completely broken and hydrated. The apparent viscosity of the base liquid measured by a six-speed rotational viscometer was 45mPa.s, and the pH was 11; the rheological pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com