High temperature resistant seawater based fracturing fluid thickener and preparation method thereof

A technology of high temperature resistance and thickening agent, which is applied in the field of fracturing and production stimulation. It can solve the problems of good viscosity increase and no mention of temperature resistance, and achieve the effects of good sand carrying, saving manpower and material costs, and low damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

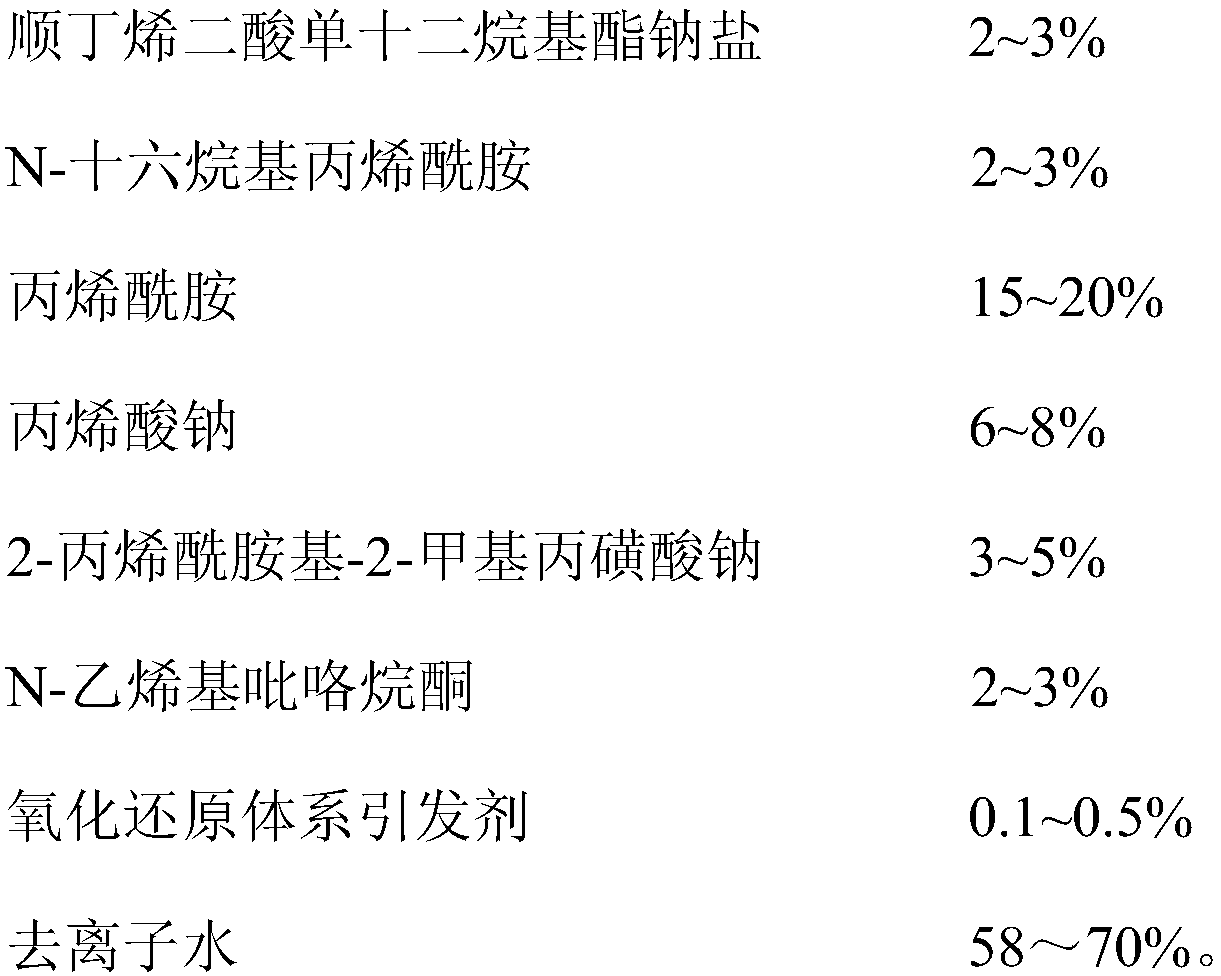

[0077] The preparation method of the high-temperature-resistant seawater-based fracturing fluid thickener of the present embodiment is as follows:

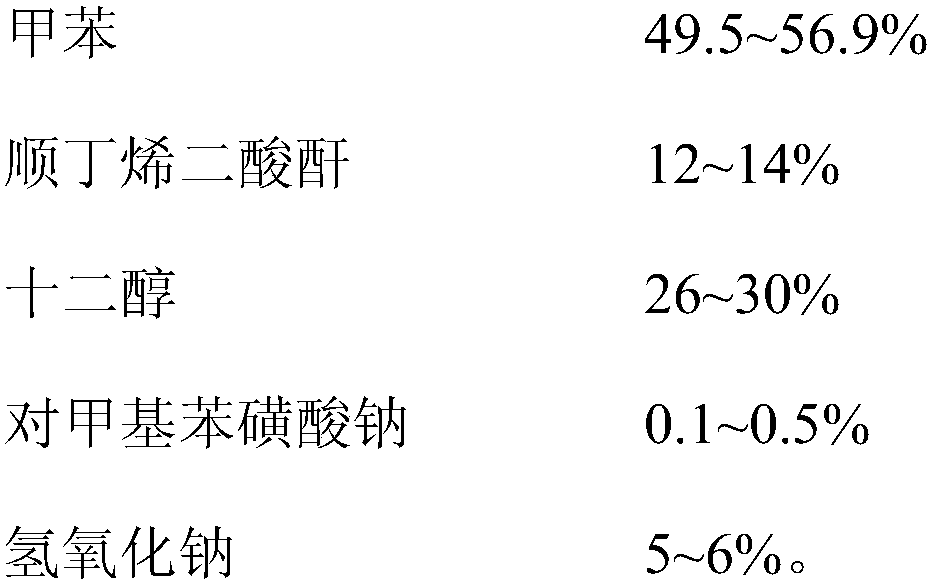

[0078] 1) Synthesis of monododecyl maleate sodium salt:

[0079] Keep the temperature in the reactor at 10°C, add 103.6g of toluene solvent, 26g of maleic anhydride and stir until dissolved, add 60g of dodecyl alcohol and 0.4g of sodium p-toluenesulfonate and stir until dissolved; close the reactor and heat up to 60°C After reacting for 12 hours, 10 g of sodium hydroxide was used for neutralization reaction for 3 hours, cooled to room temperature and then filtered. The obtained white solid was monododecyl maleate sodium salt, which was set aside.

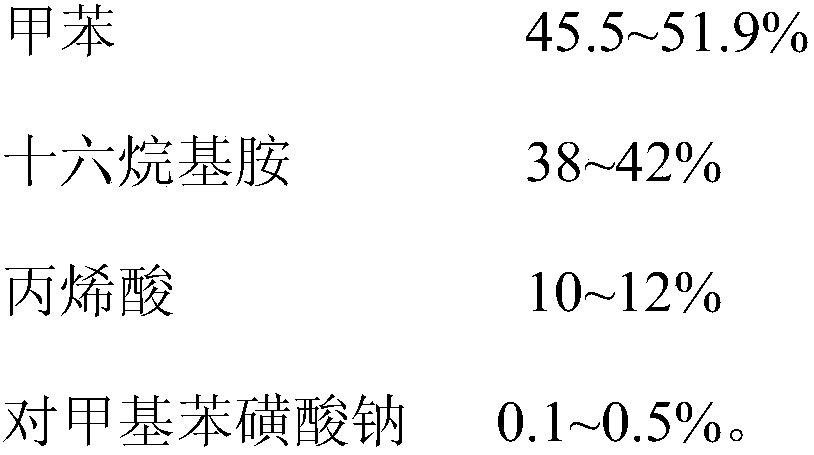

[0080] 2) Synthesis of N-hexadecyl acrylamide:

[0081]Keep the temperature in the reactor at 20°C, add 99g of toluene solvent, 76g of hexadecylamine and stir until dissolved, add 24g of acrylic acid and 1g of sodium p-toluenesulfonate and stir until dissolved; heat up to 85°C after se...

Embodiment 2

[0087] The preparation method of the high-temperature-resistant seawater-based fracturing fluid thickener of the present embodiment is as follows:

[0088] 1) Synthesis of monododecyl maleate sodium salt:

[0089] Keep the temperature in the reactor at 30°C, add 168.3g of toluene solvent, 36g of maleic anhydride and stir until dissolved, add 78g of dodecanol and 1.2g of sodium p-toluenesulfonate and stir until dissolved; close the reactor and heat up to 80°C After reacting for 8 hours, 16.5 g of sodium hydroxide was used for neutralization reaction for 2 hours, cooled to room temperature and then filtered. The obtained white solid was monododecyl maleate sodium salt, which was set aside.

[0090] 2) Synthesis of N-hexadecyl acrylamide:

[0091] Keep the temperature in the reactor at 30°C, add 146.1g of toluene solvent, 120g of hexadecylamine and stir until dissolved, add 33g of acrylic acid and 0.9g of sodium p-toluenesulfonate and stir until dissolved; close the reactor and ...

Embodiment 3

[0097] The preparation method of the high-temperature-resistant seawater-based fracturing fluid thickener of the present embodiment is as follows:

[0098] 1) Synthesis of monododecyl maleate sodium salt:

[0099] Keep the temperature in the reactor at 20°C, add 257.5g of toluene solvent, 70g of maleic anhydride and stir until dissolved, add 140g of dodecyl alcohol and 2.5g of sodium p-toluenesulfonate and stir until dissolved; close the reactor and heat up to 70°C After reacting for 10 hours, 30 g of sodium hydroxide was used for neutralization reaction for 4 hours, cooled to room temperature and then filtered. The white solid obtained was maleic acid monododecyl ester sodium salt, which was set aside.

[0100] 2) Synthesis of N-hexadecyl acrylamide:

[0101] Keep the temperature in the reactor at 10°C, add 239.5g of toluene solvent, 210g of hexadecylamine and stir until dissolved, add 50g of acrylic acid and 0.5g of sodium p-toluenesulfonate and stir until dissolved; close ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com