A kind of composite plugging agent for oil-based drilling fluid and preparation method thereof

An oil-based drilling fluid and composite technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of low leakage plugging success rate, improve the leakage plugging success rate, wide source of raw materials, and on-site operation. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

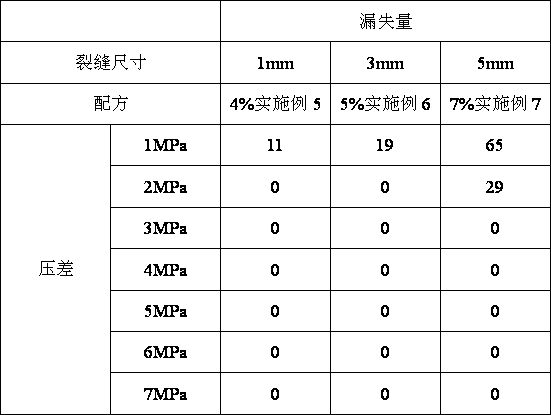

Embodiment 1

[0028] In order to overcome the problem of low plugging success rate in the prior art, the invention provides a composite plugging agent for oil-based drilling fluid and its preparation method. The principle of the composite plugging agent is to use inert three-dimensional plugging materials, pro- Oil-based two-dimensional sheet material and one-dimensional fiber material are bridged to form a plugging layer. At the same time, the time-delayed expansion oil-swellable material and lipophilic ultrafine particle material enter the plugging layer to seal and limit penetration. The composite plugging agent can significantly improve the plugging success rate of oil-based drilling fluid.

[0029] A composite plugging agent for oil-based drilling fluid: raw materials by weight percentage:

[0030] Plugging material 20%;

[0031] Fiber material 0.5%;

[0032] Oil swelling material 20%;

[0033] Lipophilic ultrafine particle material 40%;

[0034] Lipophilic sheet material 19.5%.

...

Embodiment 2

[0038] A composite plugging agent for oil-based drilling fluid: raw materials by weight percentage:

[0039] Plugging material 35%;

[0040] Fiber material 1%;

[0041] Oil swelling material 19%;

[0042] Lipophilic ultrafine particle material 30%;

[0043] Lipophilic sheet material 15%.

[0044] The plugging material has good lipophilic dispersibility. In the past, most of the plugging agents used hydrophilic plugging materials. The core materials of the composite plugging agent for oil-based drilling fluid of the present invention include two-dimensional flake material elastic graphite, ultra-fine particle material talc powder and delayed expansion All oil-swellable materials are lipophilic materials, which can be well dispersed in oil-based drilling fluids to avoid agglomeration and exert the effect of leak prevention and plugging.

[0045] In this embodiment, the plugging material is limestone powder, and the limestone powder in the plugging material is used in combin...

Embodiment 3

[0052] In this embodiment, a composite plugging agent for oil-based drilling fluid: raw materials by weight percentage:

[0053] Plugging material 50%;

[0054] Fiber material 2%;

[0055] Oil swelling material 18%;

[0056] Lipophilic ultrafine particle material 20%;

[0057] Oleophilic sheet material 10%.

[0058] The plugging material has good lipophilic dispersibility. In the past, most of the plugging agents used hydrophilic plugging materials. The core materials of the composite plugging agent for oil-based drilling fluid of the present invention include two-dimensional flake material elastic graphite, ultra-fine particle material talc powder and delayed expansion All oil-swellable materials are lipophilic materials, which can be well dispersed in oil-based drilling fluids to avoid agglomeration and exert the effect of leak prevention and plugging.

[0059] In this embodiment, the plugging material is limestone powder, and the limestone powder in the plugging materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com