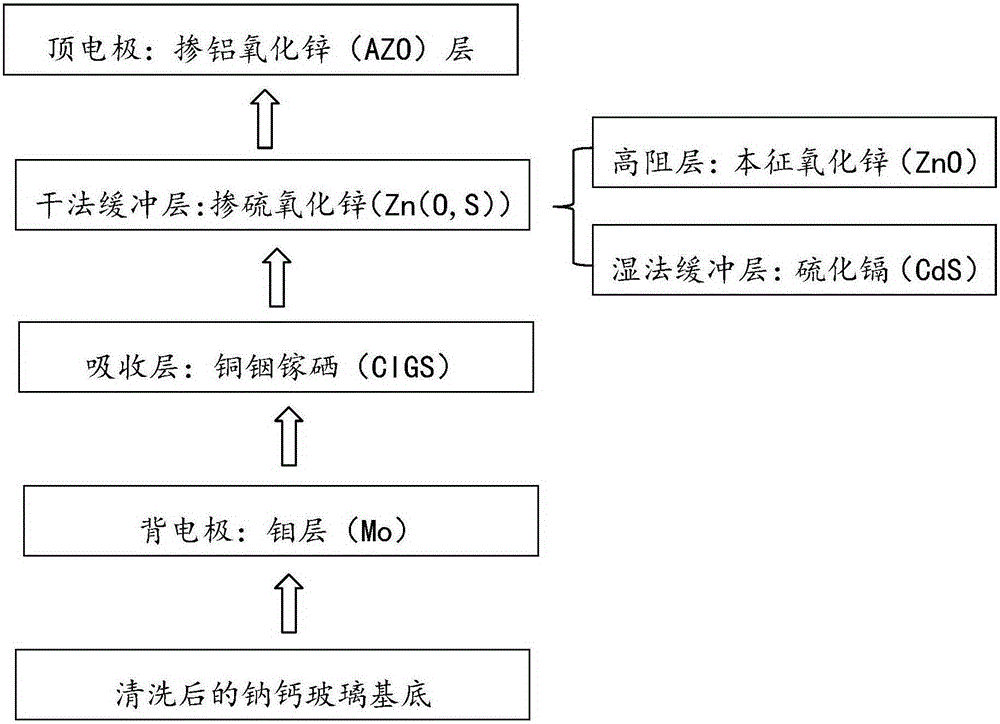

Method for manufacturing CIGS thin-film solar cell by using dry buffer layer

A solar cell and buffer layer technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor continuity of CIGS thin-film solar cells and small band gap of the buffer layer, etc., to improve continuity, improve efficiency, increase Effect of Spectral Response Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The manufacturing method of the battery is as follows:

[0037] In step 1, a Mo layer is prepared on a soda-lime glass substrate, and the thickness of the film layer is 0.8 μm.

[0038] In step 2, a CIGS layer is prepared on the Mo layer, and the thickness of the film layer is 2 μm.

[0039] Step 3: Prepare a Zn(O,S) layer on the CIGS layer by DC magnetron sputtering, wherein the atomic ratio of O to S is 15%, and the power density is 1.56W / cm 2 , the background vacuum is 3×10 -3 Below Pa, the sputtering pressure is 1Pa, and the thickness of the film layer is 100nm.

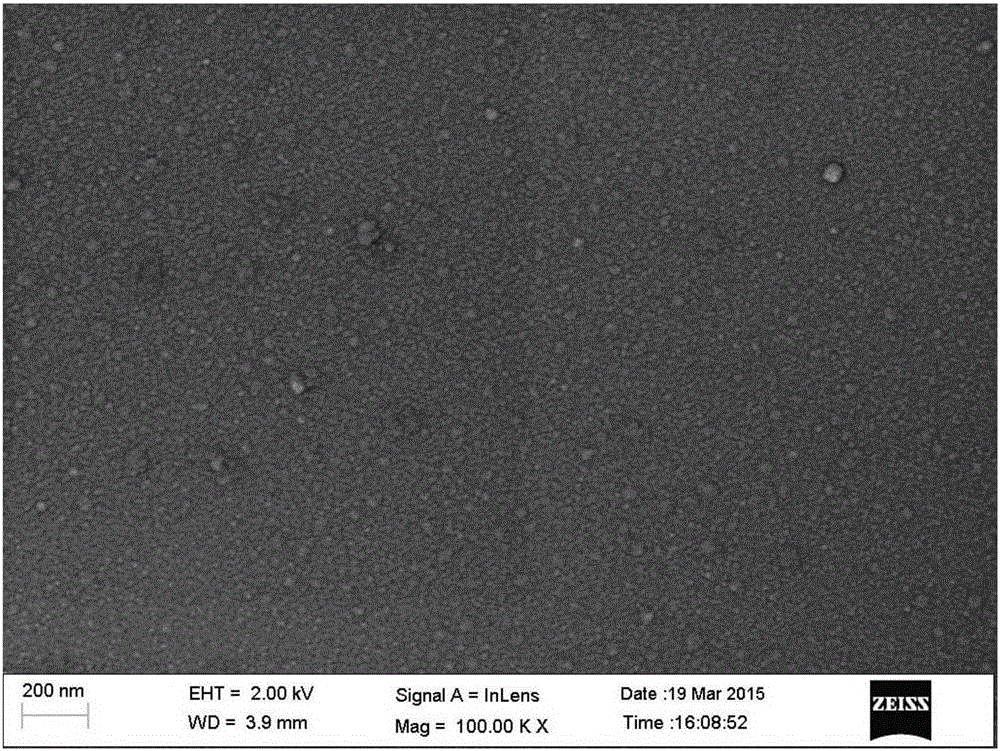

[0040] Step 4, the prepared Zn(O,S) thin film layer is annealed in the air at 150°C, and the attached image 3 And attached Figure 4 By comparison, it is found that the surface of the annealed film becomes smooth, and the average particle size does not change significantly. The annealing treatment makes the surface atoms migrate, thereby improving the surface roughness of the film.

[0041] Step five...

Embodiment 2

[0046] The third step above is to prepare a Zn(O,S) layer on the CIGS layer by using DC magnetron sputtering, wherein the atomic ratio of O to S is 30%, and the power density is 1.56W / cm 2 , the background vacuum is 3×10 -3 Below Pa, the sputtering pressure is 1Pa, and the thickness of the film layer is 100nm.

[0047] In the above step 4, the prepared Zn(O, S) thin film layer is annealed in air at 250°C, and the attached Figure 5 And attached Figure 6 By comparison, it is found that as the atomic ratio of O and S decreases, the surface roughness of the film decreases, and the surface of the film after annealing is smoother, with a significantly larger average particle size and better crystallinity.

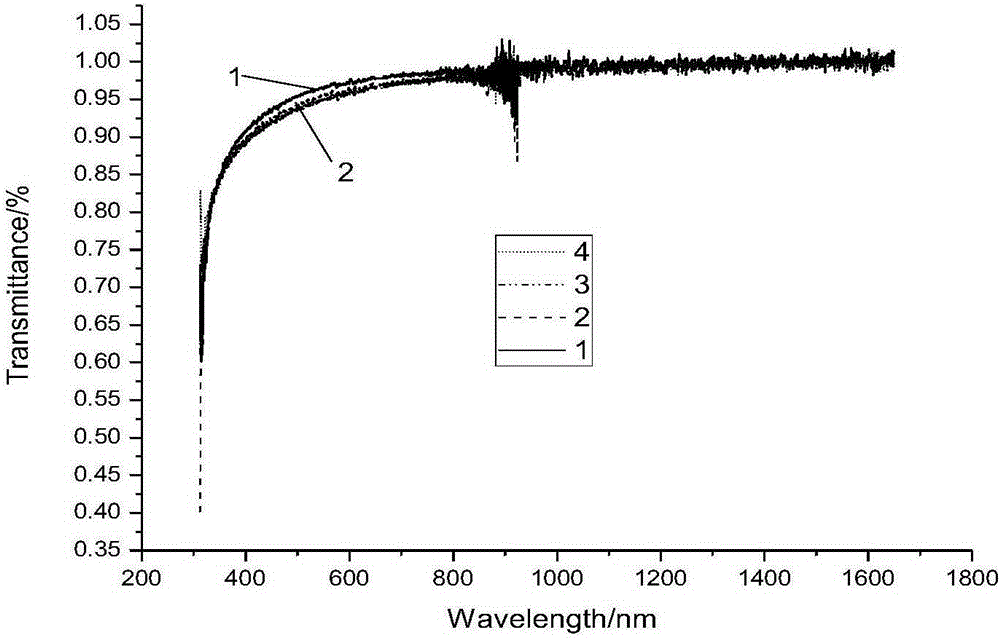

[0048] attached by figure 2 It can be seen that the transmittance of the Zn(O,S) film is higher than 90% in the range of 400-1800nm, and its band gap is 3.55eV, which is slightly lower than that of Example 1, and compared with the SLG prepared under the same conditions ( C...

Embodiment 3

[0052] The third step above is to prepare a Zn(O,S) layer on the CIGS layer by using DC magnetron sputtering, wherein the atomic ratio of O to S is 10%, and the power density is 2.33W / cm 2 , the background vacuum is 3×10 -3 Below Pa, the sputtering pressure is 1Pa, and the thickness of the film layer is 100nm.

[0053] In the above step 4, the prepared Zn(O, S) thin film layer is annealed in air at 150°C, and the attached figure 2 It can be seen that the transmittance of the Zn(O,S) film is higher than 90% in the range of 400-1800nm, but slightly lower than that of Example 1 and Example 2, and its band gap is 3.5eV, which is comparable to that of the SLG prepared under the same conditions. Compared with the (soda-lime glass) / Mo / CIGS / CdS / ZnO / AZO structure, the opening voltage can be increased by 3%-5%, the battery efficiency can be increased by 0.5%-2%, and the decrease in the band gap value is related to the decrease in the S ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com