Preparation method of visible-light response carbon-doped nano-titanium dioxide catalyst

A technology of nano-titanium dioxide and visible light, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of difficult control of hydrolysis speed, high cost of large-scale production, and harsh reaction conditions and other issues to achieve cost and time savings, simple equipment, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Measure 10ml of tetrabutyl titanate, dissolve it in 50ml of absolute ethanol, and stir to obtain A solution;

[0041] (2) Measure the ammoniacal liquor of 10ml and mix with 50ml ethanol to obtain B solution;

[0042] (3) Add solution B dropwise to solution A, stir for 30 minutes, and then react in a water bath at 60°C for 24 hours. After rapid hydrolysis of butyl titanate, a white gel is obtained at a rate of 8 drops per second.

[0043] (4) Put the white gel into a drying oven, dry it at 80°C for 12 hours, and then grind it into powder;

[0044] (5) The powder obtained is washed three times with ethanol and deionized water respectively;

[0045] (6) Dry the washed solution at 80°C for 12 hours;

[0046] (7) The above powder was calcined in a muffle furnace at 250° C. for 2 hours to obtain a carbon-doped mesoporous titanium dioxide visible light catalyst.

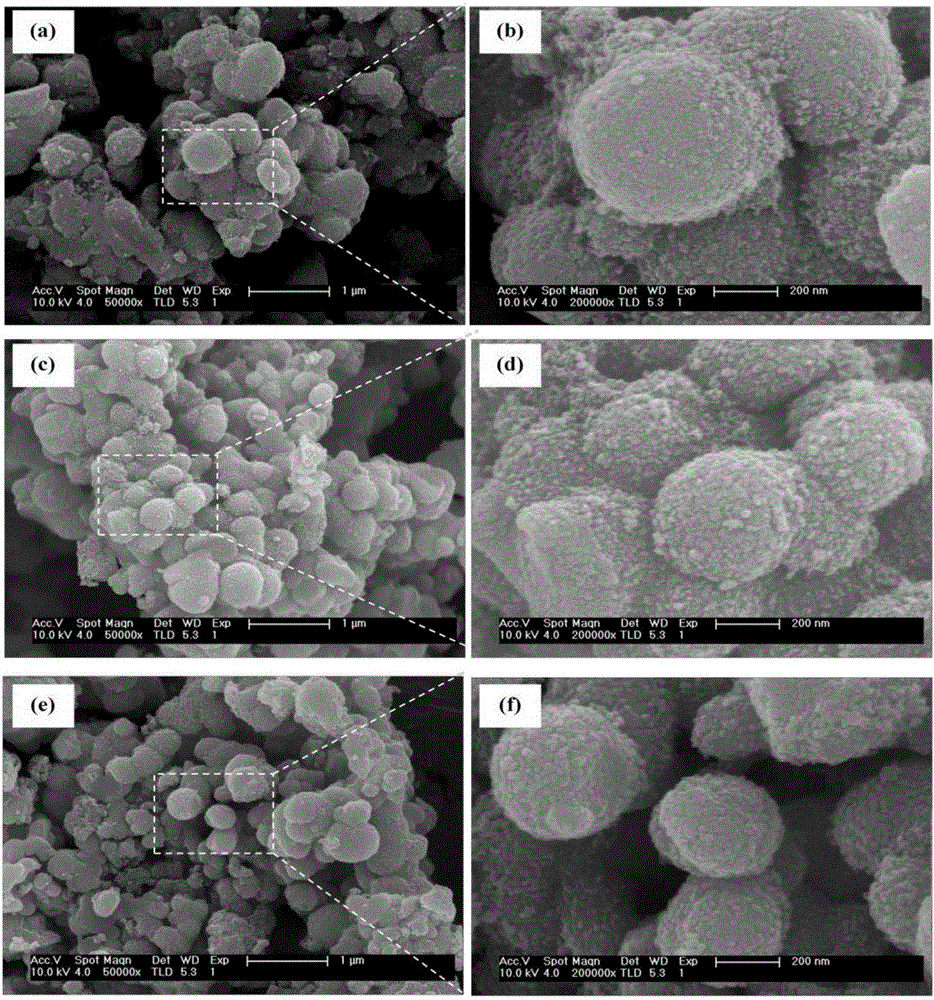

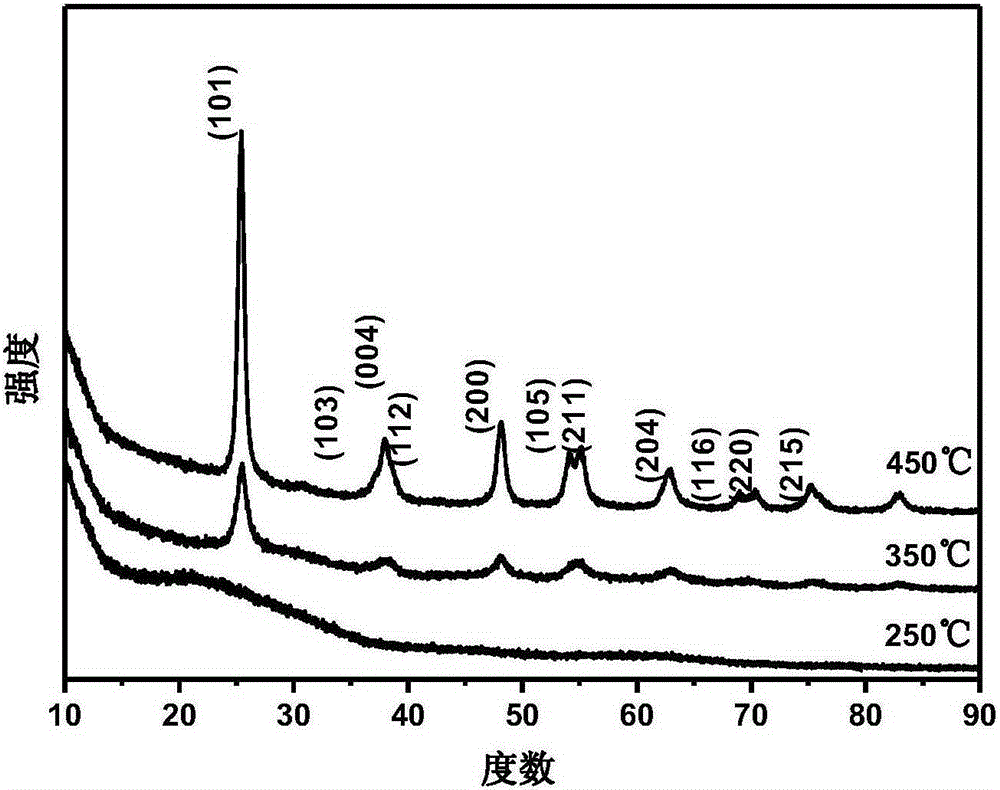

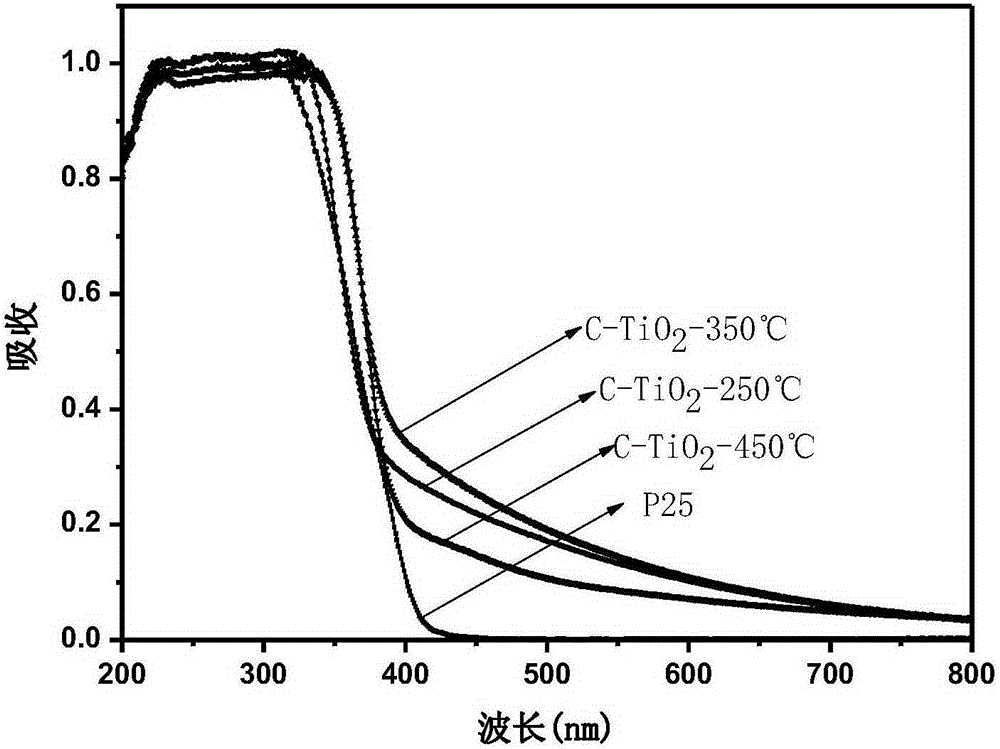

[0047] The product obtained by the reaction of step (7) is characterized by its structure and crystal form ...

Embodiment 2

[0050] (1) Measure 10ml of tetrabutyl titanate, dissolve it in 50ml of absolute ethanol, and stir to obtain A solution;

[0051] (2) Measure the ammoniacal liquor of 10ml and mix with 25ml ethanol to obtain B solution;

[0052] (3) Add solution B dropwise to solution A, stir for 30 minutes, and then react in a water bath at 60°C for 12 hours. The butyl titanate is rapidly hydrolyzed to obtain a white gel at a rate of 5 drops per second.

[0053] (4) Put the white gel into a drying oven, dry it at 80°C for 12 hours, and then grind it into powder;

[0054] (5) The powder obtained is washed three times with ethanol and deionized water respectively;

[0055] (6) Dry the washed solution at 80°C for 12 hours;

[0056] (7) The above powder was calcined in a muffle furnace at 350° C. for 2 hours to obtain a carbon-doped mesoporous titanium dioxide visible light catalyst.

[0057] The product obtained by the reaction of step (7) is characterized by its structure and crystal form by ...

Embodiment 3

[0061] (1) Measure 10ml of tetrabutyl titanate, dissolve it in 100ml of absolute ethanol, and stir evenly to obtain A solution;

[0062] (2) Measure the ammoniacal liquor of 10ml and mix with 25ml ethanol to obtain B solution;

[0063] (3) Add solution B dropwise to solution A and stir for 30 minutes, then react in a water bath at 60°C for 6 hours, and the butyl titanate will be rapidly hydrolyzed to obtain a white gel at a rate of 5 drops per second.

[0064] (4) Put the white gel into a drying oven, dry it at 80°C for 12 hours, and then grind it into powder;

[0065] (5) Wash the powder obtained six times with ethanol and deionized water respectively;

[0066] (6) Dry the washed solution at 80°C for 12 hours;

[0067] (7) The above powder was calcined in a muffle furnace at 450° C. for 2 hours to obtain a carbon-doped mesoporous titanium dioxide visible light catalyst.

[0068] The product obtained by the reaction of step (7) is characterized by its structure and crystal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com