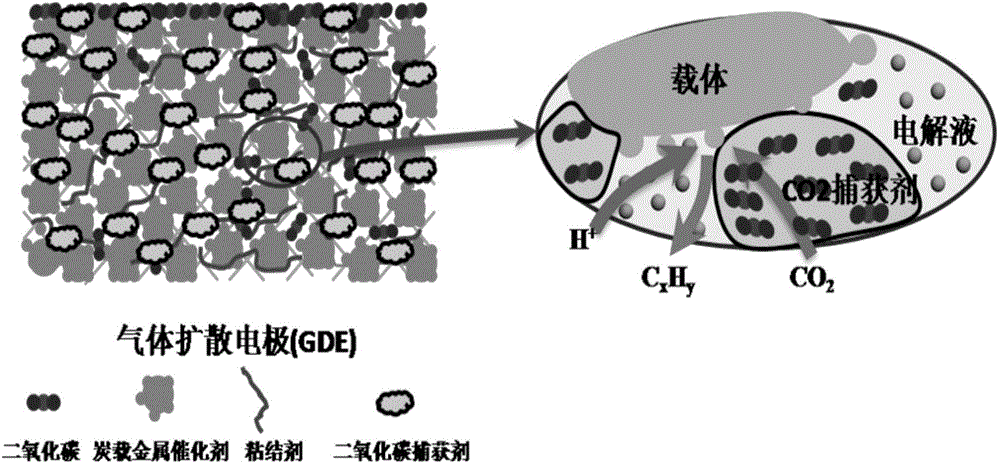

Gas diffusion electrode for carbon dioxide electrochemical reduction reaction and preparation method for gas diffusion electrode

A gas diffusion electrode and carbon dioxide technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low Faraday efficiency, hydrogen evolution side reaction suppression, etc., and achieve the goal of improving conversion rate, increasing concentration, and alleviating the problem of mass transfer polarization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Gas diffusion layer degreasing pretreatment: at room temperature, the area is 9cm 2 1. TGP-H-060 carbon paper (with a porosity of 78%) with a thickness of 0.2 mm is ultrasonically soaked in acetone for 20 minutes, then cleaned with absolute ethanol, ultrasonically soaked for 15 minutes, and finally dried with Ar gas;

[0030] 2. Catalytic layer slurry preparation:

[0031] 1) Using melamine as the N source, prepare 100 mg of nitrogen (N) hollow carbon nanospheres (N-HCS) with a particle size of 100 nm according to the method provided in the literature Chem.Commun., 2014, 50, 329-331. Among them, the mass content of N in hollow carbon nanospheres is 8.5%, CO 2 The capture capacity is 7mmolg -1 .

[0032] 2) Accurately weigh 108 mg of red copper powder with a particle size of 40 nm and 15.4 mg of nitrogen-containing (N) hollow carbon nanospheres with a particle size of 100 nm, and disperse the two in 2.5 g of propylene glycol, and disperse them uniformly by ultrason...

Embodiment 2

[0041] 1. Gas diffusion layer degreasing and impurity removal pretreatment

[0042] 1) Degreasing at room temperature, the area is 9cm 2 1. Foamed copper (90% porosity) with a thickness of 1.0 mm is ultrasonically soaked in acetone for 20 minutes, then cleaned with absolute ethanol, ultrasonically soaked for 15 minutes, and finally dried with Ar gas;

[0043] 2) Removal of impurities At room temperature, ultrasonically soak the degreased copper foam in concentrated hydrochloric acid for 15 minutes, then wash it with deionized water until the pH is neutral, wash it with absolute ethanol, soak it for 5 minutes, and finally dry it with Ar gas , stored in a desiccator for later use.

[0044] 2. Catalyst layer slurry preparation

[0045] 1) Using triphenylphosphine as the P source, prepare 100 mg of phosphorus (P) hollow carbon nanocages (P-HCC) with a particle size of 250 nm according to the method provided in the literature Chem.Commun., 2014, 50, 329-331. Among them, the mass...

Embodiment 3

[0054] 1. Gas diffusion layer degreasing and impurity removal pretreatment

[0055] 1) Degreasing

[0056] At room temperature, the area is 9cm 2 1. A copper fiber felt (85% porosity) with a thickness of 0.5 mm is ultrasonically soaked in acetone for 20 minutes, then cleaned with absolute ethanol, ultrasonically soaked for 15 minutes, and finally dried with Ar gas;

[0057] 2) Remove impurities

[0058] At room temperature, ultrasonically soak the degreased copper foam in concentrated hydrochloric acid for 15 minutes, then wash it with deionized water until the pH is neutral, wash it with absolute ethanol, soak it for 5 minutes, and finally blow it dry with Ar gas, and place it in a desiccator Save it for later use.

[0059] 2. Catalyst layer slurry preparation

[0060] 1) Using selenourea as a Se source, prepare 100 mg of phosphorus (P)-containing hollow carbon nanocapsules (P-HCC) with a particle size of 300 nm according to the method provided in the literature Chem.Comm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com