Sulfur-based biochar material, and preparation method and application thereof

A biochar and sulfur-based technology, applied to chemical instruments and methods, water pollutants, and other chemical processes, can solve the problem of low adsorption capacity, achieve low raw material costs, huge output, and simple extraction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

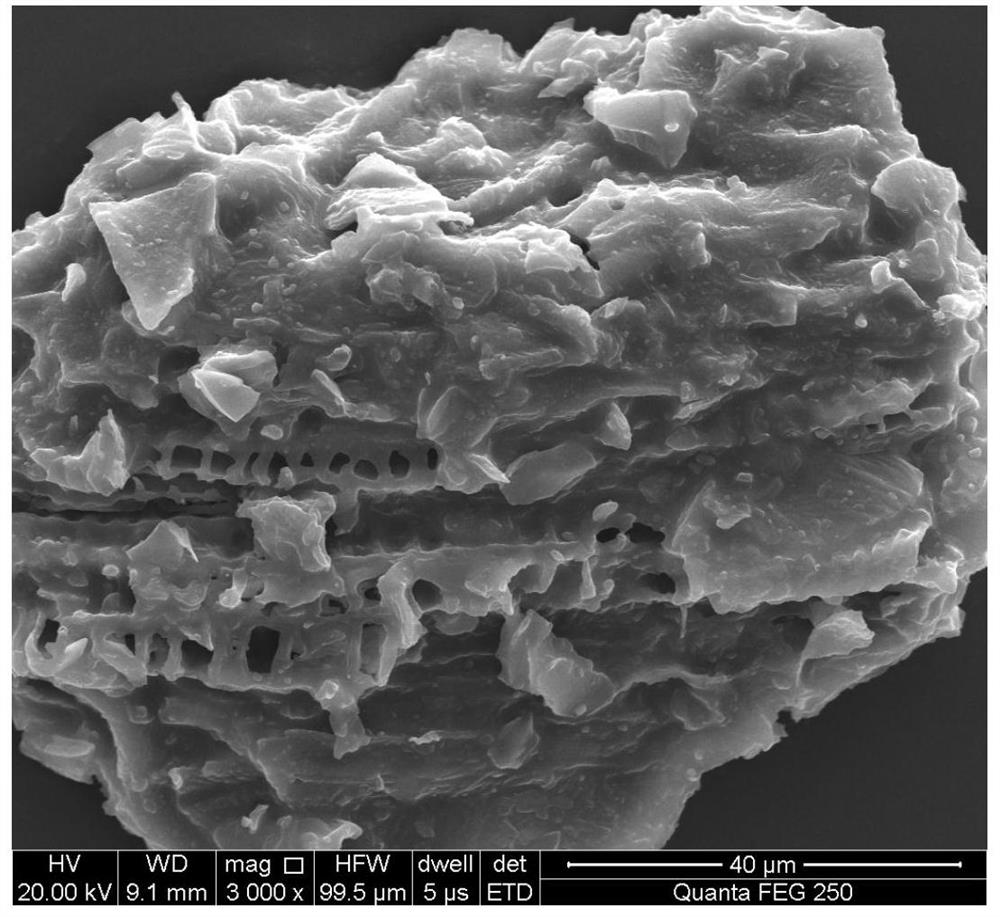

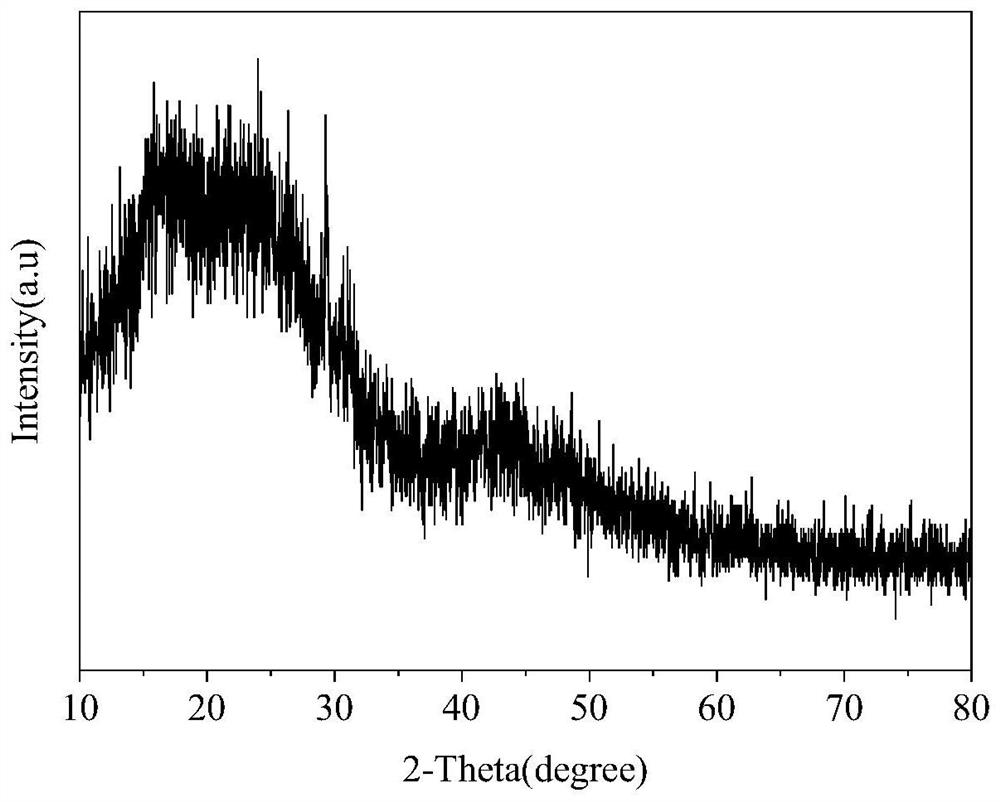

Image

Examples

Embodiment 1

[0036] In the preparation process of sulfur-based biochar described in this example, the ratio of thiolimonene to biochar is 0.3:1, and the preparation process is as follows:

[0037] (1) Put 25g of sublimed sulfur in an oil bath and heat to 170°C, then add 25g of D-limonene dropwise within 3 minutes, and react for 3 hours under magnetic stirring.

[0038] (2) After washing the pomelo peel with deionized water for 3 times, put it in an oven at 105°C and dry it for 1 day; grind it with a mortar for 10 minutes to make the particle size pass through a 10-mesh sieve.

[0039] (3) Put the dried and ground pomelo peel in a 200ml aluminum box, the volume of the aluminum box is Cover it, put it into the muffle furnace, set the heating rate to 300°C / h, the carbonization temperature to 600°C, and the holding time to 2h.

[0040] (4) Put 0.3 g of thiolimonene prepared in step (1) in a 100ml porcelain crucible, put it on a heating plate, set the temperature of the heating plate to 140° ...

Embodiment 2

[0043] In the preparation process of sulfur-based biochar described in this example, the ratio of thiolimonene to biochar is 0.6:1, and the preparation process is as follows:

[0044] Other conditions are the same as in Example 1, except that in step (4), 0.6 g of thiolimonene produced in step (1) is placed in a 100 ml porcelain crucible, placed on a heating plate, and the temperature of the heating plate is set at 140 ° C. After 5 minutes, Thiolimonene was melted to a flow state, and 1 g of biochar prepared in step (3) was added, stirred with a glass rod every 20 min for 1 min, and reacted for 3 h. That is, sulfur-based biochar is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com