Organic field-effect tube of composite channel

A composite channel and organic field technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of less interface and insufficient number of carriers, and achieve high switching current ratio and high current carrying capacity The effect of submobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

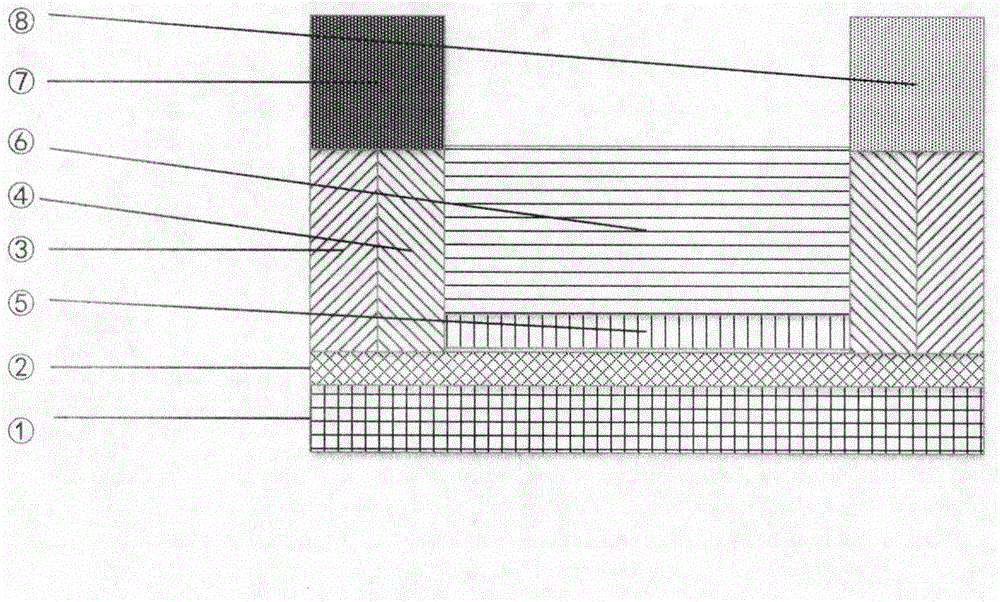

[0018] An organic field effect transistor with a composite channel, the preparation steps of which are as follows:

[0019] 1) The heavily doped silicon wafer was ultrasonically cleaned with acetone, ethanol, and deionized water for 30 minutes, and then dried in a glove box for 1 hour to clean the surface of the heavily doped silicon wafer;

[0020] 2) Place the above heavily doped silicon wafer in a UV / ozone environment for 120 minutes to obtain SiO 2 gate dielectric layer;

[0021] 3) On SiO 2 Positive photoresist is coated on the gate dielectric layer, and after pre-baking, exposure, development, and film hardening processes, ③ is obtained by photolithography. Pentacene active layer, control the evaporation rate as The vacuum degree is 1×10 -4 Pa; remove the glue after evaporation;

[0022] 4) Repeat step 3) to obtain ④ by photolithography, and the channel length is 200nm; then use the vacuum coating method to evaporate a 30nm thick C60 active layer on the heavily dop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com