Alumina carrier and preparation method thereof

An alumina carrier, alumina technology, applied in catalyst carriers, chemical instruments and methods, organic chemistry, etc., can solve the problems of increased propane cracking reaction, carbon deposition, accelerated catalyst deactivation rate, etc., to achieve high carbon capacity, Stability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

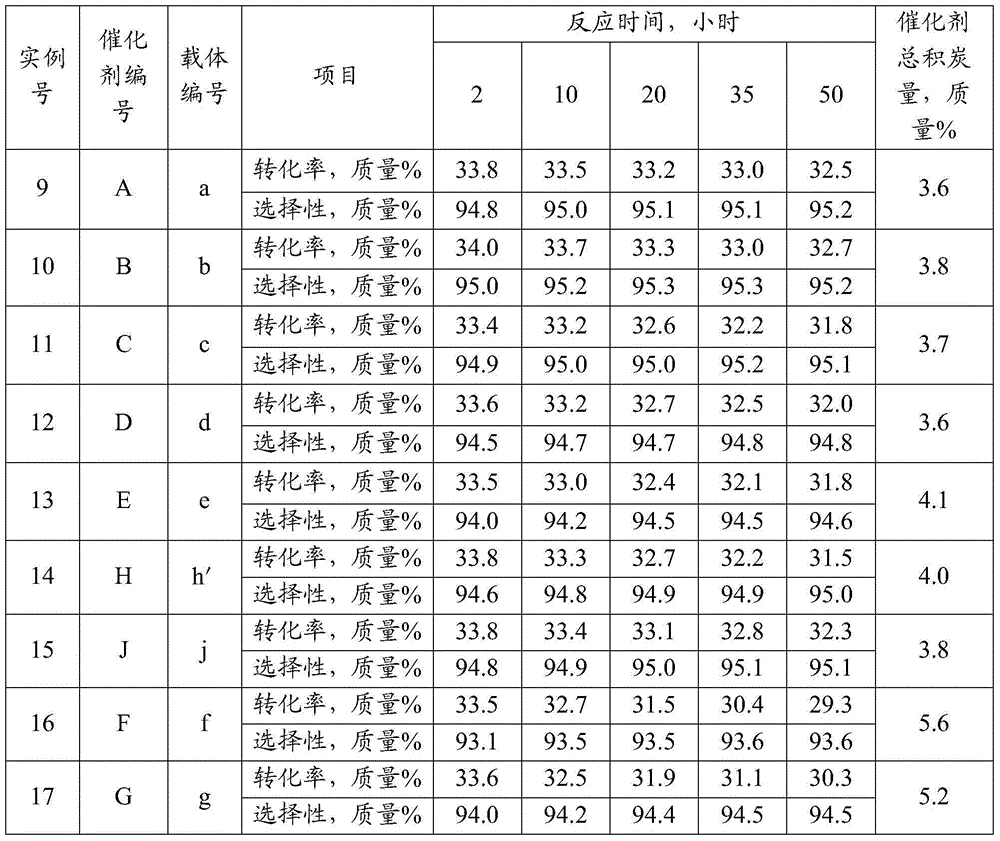

Examples

preparation example Construction

[0019] The preparation method of spherical carrier of the present invention comprises the following steps:

[0020] (1) Add acid peptization to aluminum hydroxide to obtain alumina sol, add pore expander to alumina sol, drop ball forming,

[0021] (2) After drying the wet balls formed in step (1), one-stage calcination is carried out at 620-680°C, and then the temperature is raised to 900-1100°C for two-stage calcination to obtain the carrier.

[0022] In the above-mentioned method, (1) step is to form with alumina sol dropping ball, the pore-enlarging agent that adds in aluminum sol preferably C 10 ~C 16 hydrocarbons, urea or ammonium carbonate. The C 10 ~C 16 The preferred hydrocarbon is kerosene, and the ammonium carbonate salt is preferably ammonium bicarbonate or ammonium carbonate.

[0023] The mass ratio of the added pore-enlarging agent to the alumina contained in the aluminum sol is 0.05-0.6, preferably 0.1-0.5.

[0024] There are many ways to prepare alumina so...

example 1

[0043] Get 27g of aluminum flakes, add 610 grams of hydrochloric acid solution with a concentration of 18% by mass, dissolve the aluminum flakes, obtain a solution with an aluminum chloride content of 4% by mass, transfer it to a neutralization tank, and add 850 grams of a solution with a concentration of 6% by mass. mass % ammonia water, mixed uniformly at 60°C, and the pH value is 7.5-8.5. The generated aluminum hydroxide was filtered and washed, and 9 mL of nitric acid with a volume ratio of 1:1 was added to the filter cake for acidification, and 40 mL of a solution containing 30 grams of urea and a hydrochloric acid solution containing 32 grams of stannous chloride were added under stirring to make the solution The Sn content in is 0.32% of dry base alumina quality, stirs 1 hour to acidify, then adds 30 grams of kerosene and 3 grams of nonylphenol polyoxyethylene ethers and stirs for 1 hour, in the sol with Al 2 o 3 The calculated solid content was 20% by mass. The sol i...

example 2

[0045] Prepare the alumina carrier according to the method of Example 1, the difference is to get 132 grams of aluminum hydroxide powder (produced by German Sasol company, brand SB, the alumina content is 76% by mass), add 100mL deionized water, stir for 1 hour to make it slurry Then add 9 mL of nitric acid with a volume ratio of 1:1 to acidify the aluminum sol, and the obtained tin-containing θ-Al 2 o 3 The physical properties of carrier b are listed in Table 1.

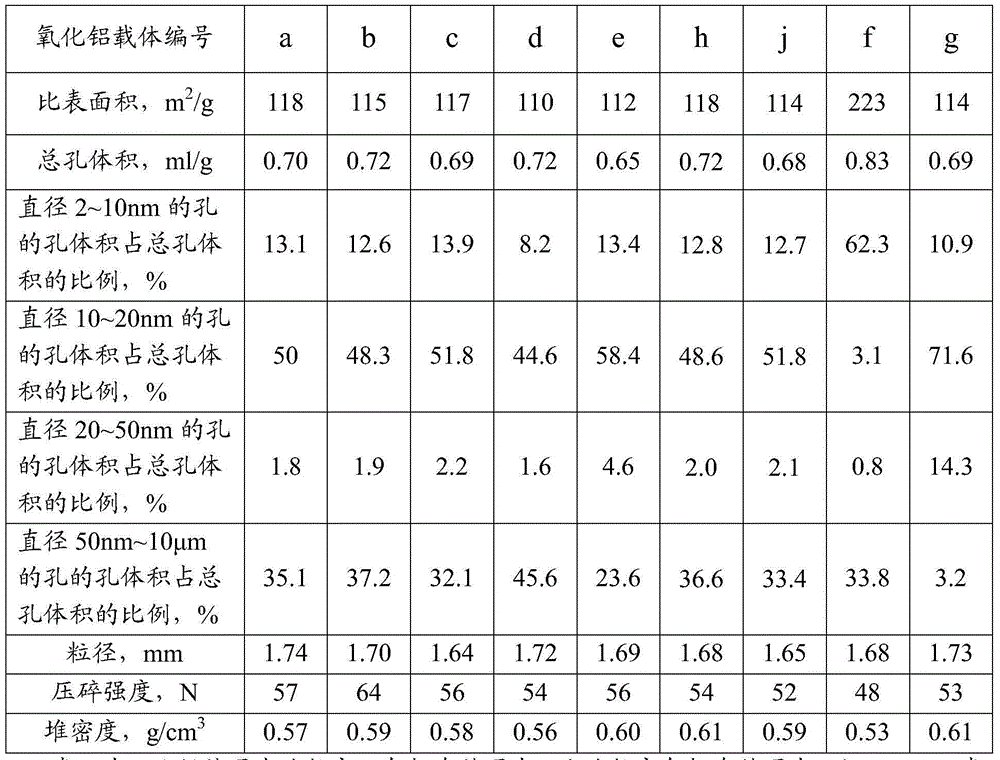

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com