Anti-poisoning blast furnace gas hydrolysis catalyst with high specific surface area and preparation method thereof

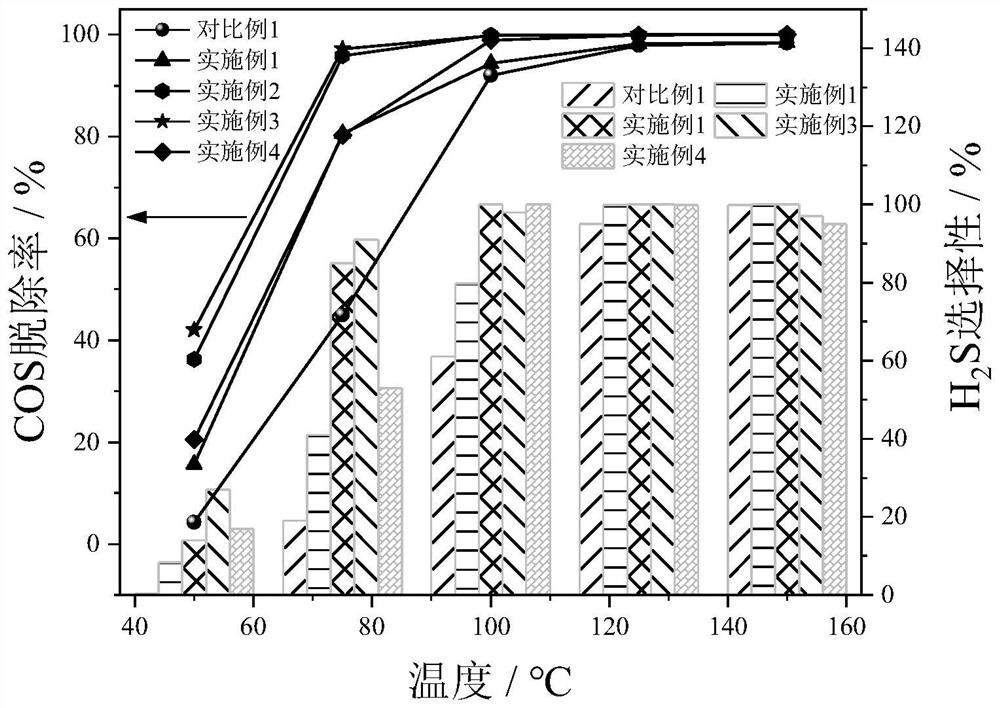

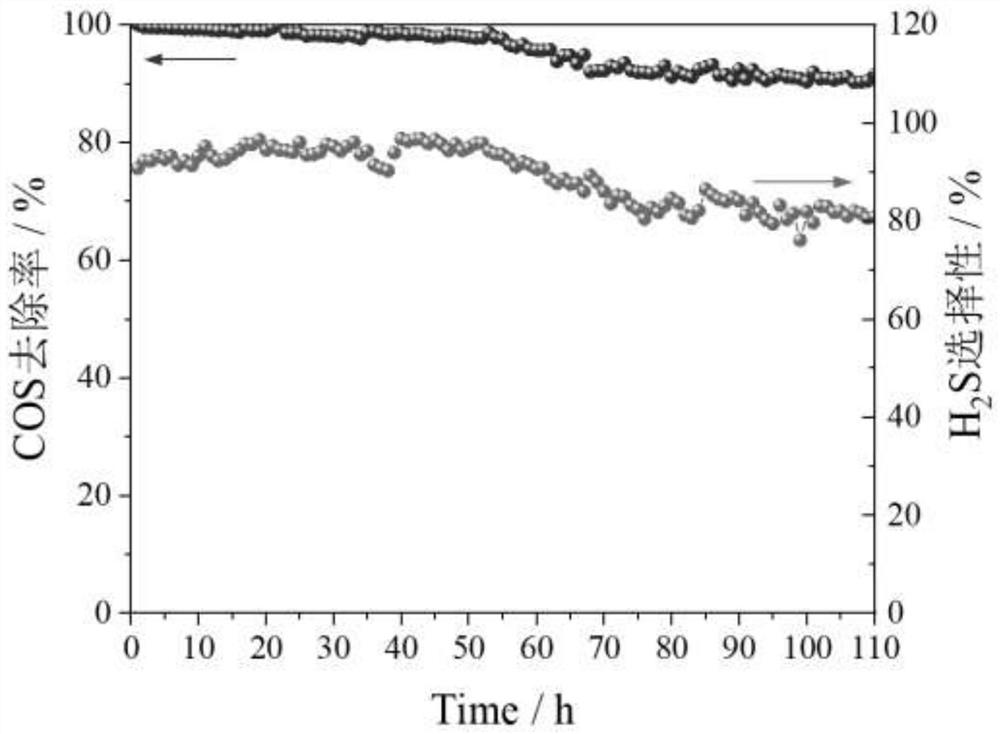

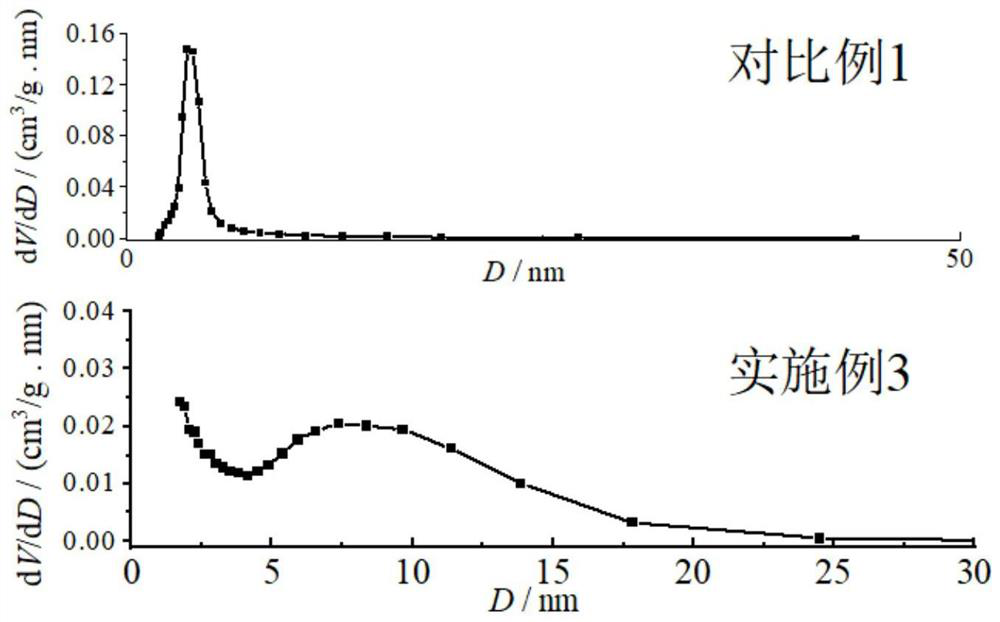

A high specific surface area, hydrolysis catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical elements of heterogeneous catalysts, etc., can solve problems such as decreased desulfurization efficiency, increase the proportion of macropores, and promote low-temperature hydrolysis. The effect of increasing activity and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The catalyst raw materials are: 5g of aluminum nitrate, 0.036g of polyvinyl alcohol, 0.043g of holmium nitrate, and 0.216g of potassium carbonate.

[0035] making process:

[0036] First, dissolve aluminum nitrate, potassium carbonate, and holmium nitrate in 50mL of deionized water, add polyvinyl alcohol, and stir until completely dissolved; then, under ultrasonic conditions of 80kHz, slowly add 5ml of ammonia water, ultrasonic for 10min, until the solution is uniform Then add 5ml of ammonia water again, and circulate until the pH reaches 10. After standing at 40°C for 24h, the obtained emulsion was stirred in a magnetic stirrer at a speed of 60r / min for 4h at 60°C, dried in an oven at 110°C for 24h, taken out and ground to below 100 mesh. Calcined in a furnace at 700°C for 6 hours to produce polyvinyl alcohol, Ho, K, Al 2 o 3 A hydrolysis catalyst with a mass ratio of 0.05:0.001:0.05:1.

Embodiment 2

[0038] The catalyst raw materials are: 5g of titanium dioxide, 0.072g of polyacrylamide, 0.214g of neodymium nitrate and 0.562g of sodium carbonate.

[0039]First, dissolve aluminum nitrate, sodium carbonate and neodymium nitrate in 50mL of deionized water, add polyacrylamide, and stir until completely dissolved; then, under ultrasonic conditions of 100kHz, slowly add 10ml of ammonia water, ultrasonic for 8min, until the solution is uniform Then add 10ml of ammonia water again, and circulate until the pH reaches 10. After the obtained emulsion was left to stand at 50°C for 24h, it was stirred in a magnetic stirrer at a speed of 60r / min at 70°C for 4h, dried in an oven at 120°C for 24h, taken out and ground to below 100 mesh. Calcined at 650°C for 6h in the furnace to produce polyacrylamide, Nd, Na, Al 2 o 3 A hydrolysis catalyst with a mass ratio of 0.10:0.005:0.10:1.

Embodiment 3

[0041] The preparation steps are the same as in Example 1, except that the catalyst raw materials are: 5g of titanium dioxide, 0.036g of dodecylbenzenesulfonic acid, 0.212g of lanthanum nitrate and 0.806g of calcium acetate.

[0042] The prepared catalyst is dodecylbenzenesulfonic acid, La, Ca, Al 2 o 3 A hydrolysis catalyst with a mass ratio of 0.05:0.005:0.15:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com