A composite hierarchical porous molecular sieve catalyst for producing aromatics from low-carbon alkanes and its preparation method

A low-carbon alkane and molecular sieve technology, which is applied in molecular sieve catalysts, catalyst activation/preparation, chemical instruments and methods, etc., to achieve the effects of simple and easy preparation method, excellent low-carbon alkane aromatization performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Synthesis of hierarchical porous molecular sieves:

[0039] Silica sol is used as a silicon source, aluminum nitrate is used as an aluminum source, and tetrapropylammonium bromide is used as a template. SiO 2 :Al 2 o 3 :Na 2 O:TPABr:H 2 The molecular molar ratio of O=1:0.033:0.005:0.06:60 is made into a synthetic solution, and HNO is used 3 Control the pH value at about 11.0, then add carbon nanotubes accounting for 25% of the mass of the silica sol and stir for ~60 minutes; then crystallize in a dynamic crystallization kettle at 170°C for 72 hours to obtain a molecular sieve slurry, which is washed, filtered and dried. Na-ZSM-5 was obtained by calcining at 600°C for 6h under flowing air. Under the condition of liquid-to-mass ratio of 10:1, Na-type molecular sieve and 1mol / L NH 4 NO 3 The solution was exchanged for 3 times, dried, and calcined at 500°C for 4 hours to obtain the required multi-stage HZSM-5 molecular sieve raw material.

[0040] (2) catalyst ...

Embodiment 2

[0046] (1) Synthesis of hierarchical porous molecular sieves:

[0047] Silica sol is used as a silicon source, aluminum nitrate is used as an aluminum source, and tetrapropylammonium bromide is used as a template. SiO 2 :Al 2 o 3 :Na 2 O:TPABr:H 2 The ratio of O=1:0.011:0.005:0.06:60 is made into a synthetic solution, HNO 3 Control the pH value at about 11.0, add mesoporous carbon with 30% silica sol mass and stir for ~60min; the subsequent preparation process is the same as step (1) in Example 1.

[0048] (2) catalyst preparation:

[0049] 1) Mix the weighed multi-stage pore ZSM-5 molecular sieve, MCM-22 molecular sieve with a silicon-aluminum ratio of 25, and gallium nitrate, then add 1.5 times the total mass of deionized water to form a slurry and ball mill in a ball mill; take out the ball mill for 30 minutes and add Deionized water with 4 times the solid mass, and stirred at 70°C for 8h; then the above solution was spray-dried to obtain micropowder, and calcined at...

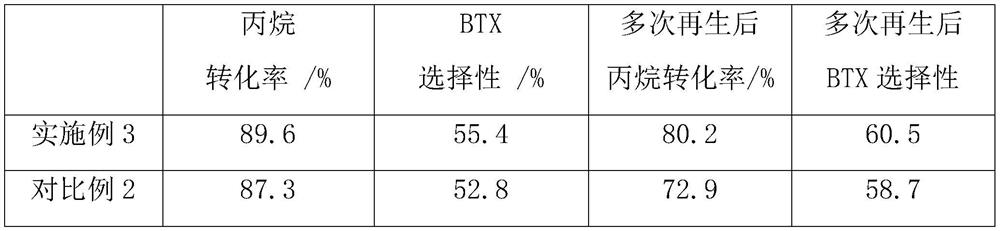

Embodiment 3

[0054] (1) Synthesis of hierarchical porous molecular sieves:

[0055] Silica sol is used as a silicon source, aluminum nitrate is used as an aluminum source, and tetrapropylammonium bromide is used as a template. SiO 2 :Al 2 o 3 :Na 2 O:TPABr:H 2 The ratio of O=1:0.02:0.005:0.06:60 is made into a synthetic solution, HNO 3 Control the pH value at about 11.0, add carbon nanotubes with 35% silica sol mass and stir for ~60 min; the subsequent preparation process is the same as step (1) in Example 1.

[0056] (2) catalyst preparation:

[0057] 1) Mix the weighed multi-stage pore ZSM-5 molecular sieve, MCM-22 molecular sieve with a silicon-aluminum ratio of 40, and zinc nitrate, then add 2.5 times the total mass of deionized water to form a slurry and ball mill in a ball mill; take out the ball mill for 30 minutes and add 3.5 times the solid mass of deionized water, and stirred at 80°C for 5 hours; then the above solution was spray-dried to obtain micropowder, and calcined a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com