Gas sensor based on graded porous WO3 microspheres and preparation method thereof

A gas sensor, hierarchical porous technology, applied in separation methods, chemical instruments and methods, and techniques for producing decorative surface effects, etc., can solve the problems of high energy consumption, blank, sensor integration complexity, etc., to achieve response and The recovery time is short, the output is large, and the effect of solving the problem of poor gas sensitivity characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

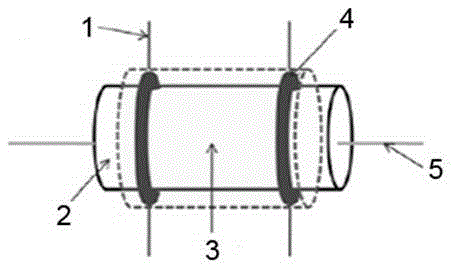

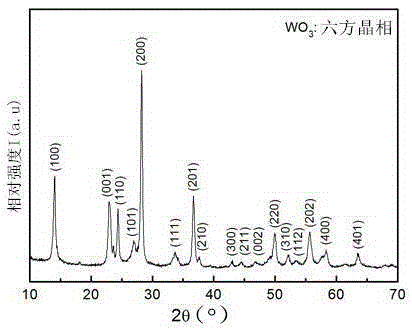

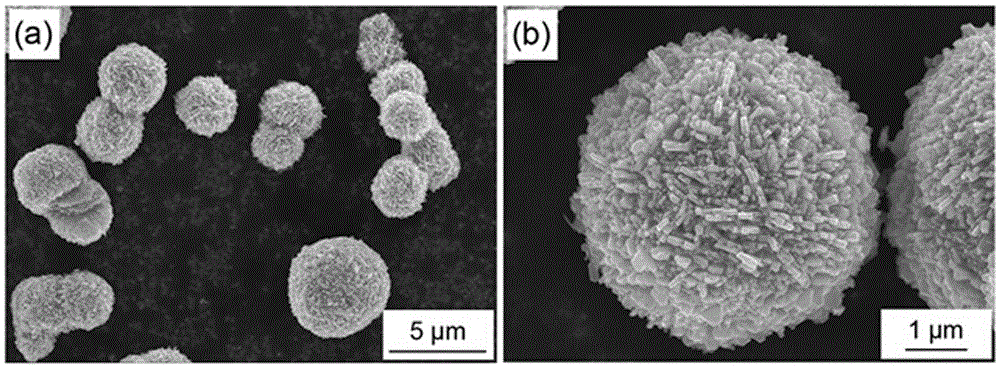

[0028] Based on hierarchical porous WO of this embodiment 3 Gas sensors with microspheres, such as figure 1 As shown, it includes a platinum wire 1, a ceramic tube 2, a gas-sensitive coating 3, an interdigitated gold electrode 4 and a heating wire 5, wherein the heating wire 5 passes through the ceramic tube 2 and welds its two ends to the base On the heating electrode of the seat, the interdigitated gold electrode 4 is covered on the outer surface of the ceramic tube 2 and welded on the measuring electrode of the base through the platinum wire 1, and the gas-sensitive coating 3 is coated on the outer surface of the interdigitated gold electrode 4; The composition of the gas-sensitive coating 4 is hierarchically porous WO 3 Microspheres, Graded Porous WO 3 Microspheres have a single hexagonal phase crystal structure, the size of the spheres is uniform and the individual dispersion is good, the diameter is between 3 and 5 μm, and each hierarchical porous WO 3 Microspheres ar...

Embodiment 2

[0041] Based on hierarchical porous WO of this embodiment 3 Gas sensors with microspheres, such as figure 1 As shown, the present embodiment based on hierarchical porous WO 3 Gas sensors with microspheres, such as figure 1 As shown, it includes a platinum wire 1, a ceramic tube 2, a gas-sensitive coating 3, an interdigitated gold electrode 4 and a heating wire 5, wherein the heating wire 5 passes through the ceramic tube 2 and welds its two ends to the base On the heating electrode of the seat, the interdigitated gold electrode 4 is covered on the outer surface of the ceramic tube 2 and welded on the measuring electrode of the base through the platinum wire 1, and the gas-sensitive coating 3 is coated on the outer surface of the interdigitated gold electrode 4; The composition of the gas-sensitive coating 4 is hierarchically porous WO 3 Microspheres, Graded Porous WO 3 Microspheres have a single hexagonal phase crystal structure, the size of the spheres is uniform and the ...

Embodiment 3

[0050] Based on hierarchical porous WO of this embodiment 3 Gas sensors with microspheres, such as figure 1 As shown, the present embodiment based on hierarchical porous WO 3 Gas sensors with microspheres, such as figure 1 As shown, it includes a platinum wire 1, a ceramic tube 2, a gas-sensitive coating 3, an interdigitated gold electrode 4 and a heating wire 5, wherein the heating wire 5 passes through the ceramic tube 2 and welds its two ends to the base On the heating electrode of the seat, the interdigitated gold electrode 4 is covered on the outer surface of the ceramic tube 2 and welded on the measuring electrode of the base through the platinum wire 1, and the gas-sensitive coating 3 is coated on the outer surface of the interdigitated gold electrode 4; The composition of the gas-sensitive coating 4 is hierarchically porous WO 3 Microspheres, Graded Porous WO 3 Microspheres have a single hexagonal phase crystal structure, the size of the spheres is uniform and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com