A kind of oxide film type thermocouple and preparation method thereof

A technology of oxide thin films and thermocouples, which is applied in the manufacture/processing of thermoelectric devices, thermometers with directly heat-sensitive electric/magnetic elements, and heat measurement, to improve performance, reduce heat volatilization, and high operating temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

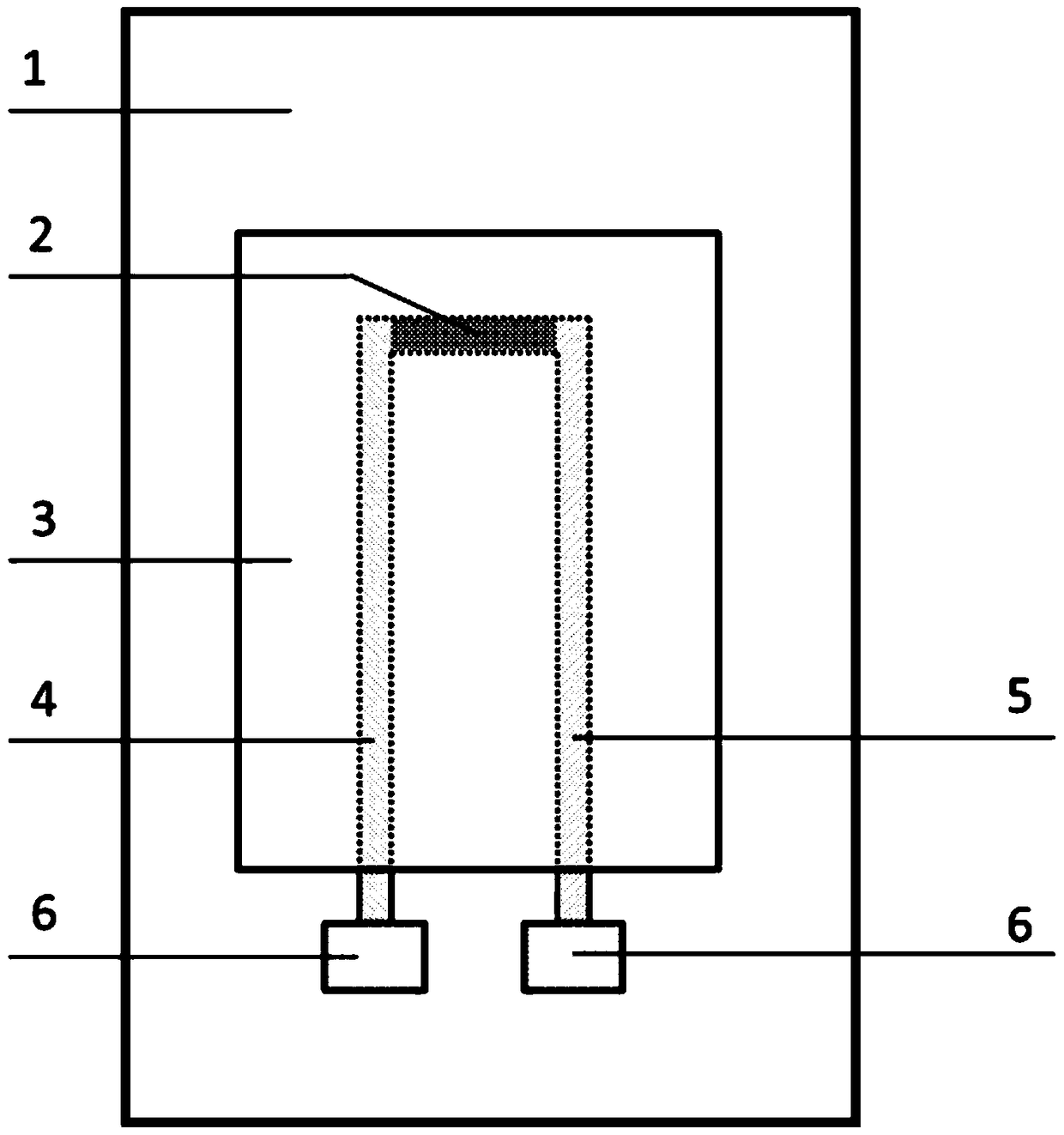

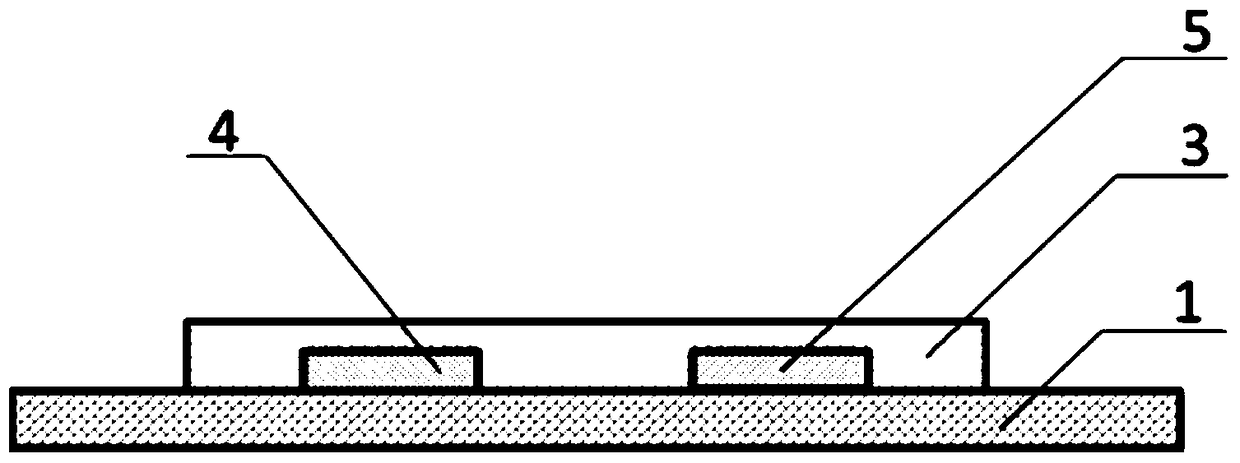

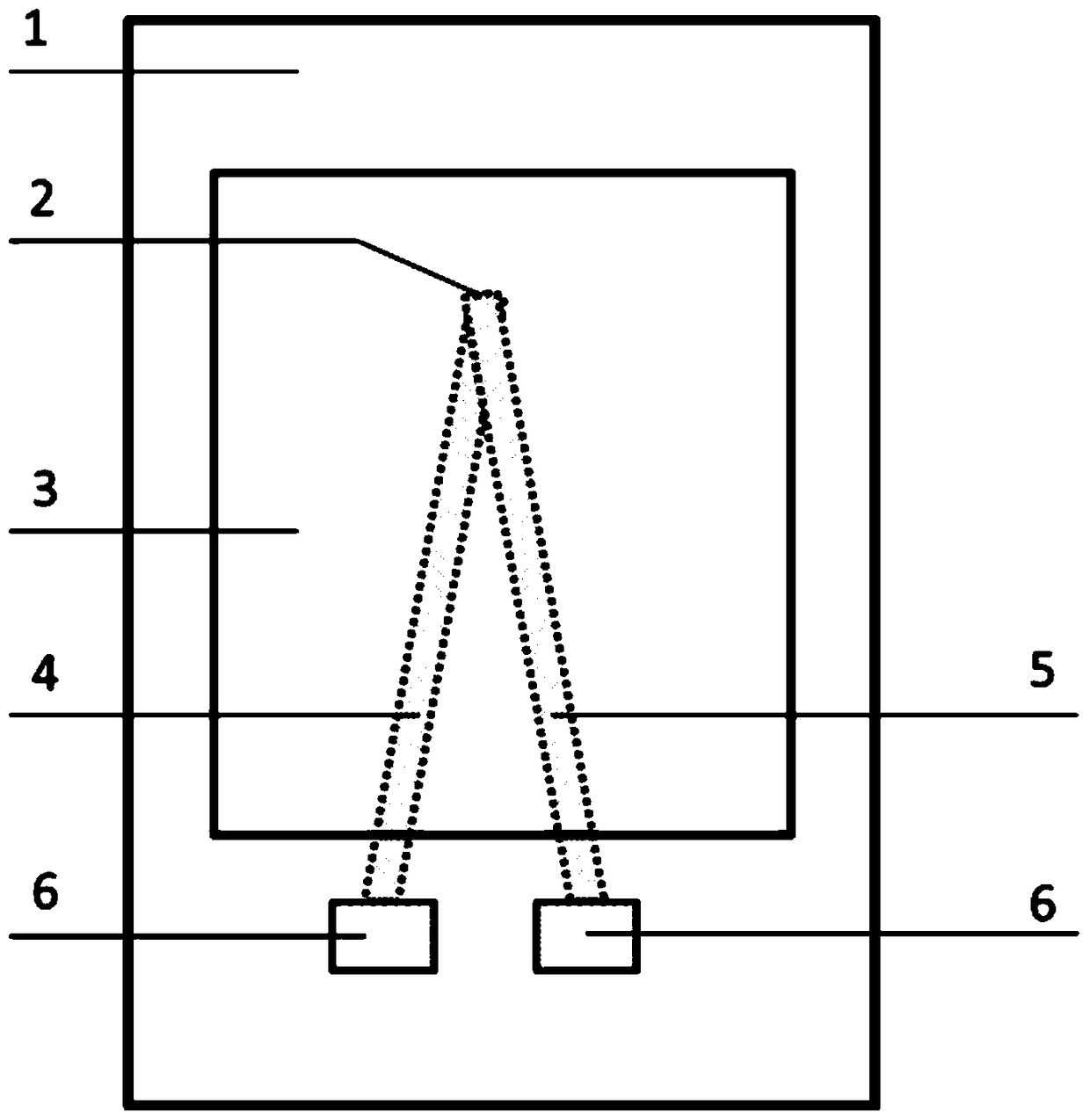

[0032] The invention discloses a method for preparing an oxide thin-film thermocouple, which uses a magnetron sputtering process to deposit and prepare an oxide thin-film thermocouple that can be used for high-temperature measurement on a high-temperature ceramic substrate 1 . In addition, the oxide protective layer 3 is applied to improve the thermal volatility of the oxide film thermocouple and improve the performance of the thermocouple. The thin-film thermocouple is directly mounted on the surface of the ceramic substrate, can be used in an oxidizing atmosphere, and can work stably for a long time at a high temperature of 1000°C-1250°C. Including the following steps:

[0033] 1) Two different oxide films of indium oxide and tin-doped indium oxide (ITO) are used as the two working thermal electrodes of the thermocouple;

[0034] 2) Using a magnetron sputtering process, combined with a patterned template technology, depositing an oxide film thermal electrode on the high-tem...

Embodiment 1

[0041] The selected ITO oxide thermal electrode component is indium tin oxide material with a tin content of 10%, and the indium oxide thermal electrode component is a single oxide with a purity of 99%. A thin film thermode is deposited on the substrate. Among them, in the magnetron sputtering process, the working carrier gas used is oxygen / argon, wherein the content of oxygen is controlled at 40%, the sputtering power is determined to be 100w, and the sputtering time is 5 hours. In order to obtain good patterning, a U-shaped structure mask with a thermal electrode length of 12 cm and a width of 0.8 cm was selected for vacuum sputtering deposition of the film. Using mask technology, first deposit ITO film on the substrate, and then sputter deposit indium oxide film. After the deposition of both film materials is completed, the film sample is heat-treated in a muffle furnace at 900°C for 1 hour, and the heating rate is kept at 5. ℃ / min, finally prepared ITO-In with a U-shaped ...

Embodiment 2

[0045] The selected ITO oxide thermal electrode component is indium tin oxide material with a tin content of 5%, and the indium oxide thermal electrode component is a single oxide with a purity of 99%. A thin film thermode is deposited on the substrate. Among them, in the magnetron sputtering process, the working carrier gas used is oxygen / argon, the content of oxygen is controlled at 50%, the sputtering power is determined to be 120w, and the sputtering time is 7 hours. In order to obtain good patterning, a U-shaped structure mask with a thermal electrode length of 25 cm and a width of 1.0 cm was selected for vacuum sputtering deposition of the film. Using mask technology, first deposit a thin film of indium oxide on the substrate, and then sputter to deposit an ITO thin film. After the deposition of both thin film materials is completed, the thin film sample is heat-treated in a muffle furnace at 1000°C for 1.2 hours, and the heating rate is maintained at 5. ℃ / min, and fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com