High-density silicon carbide brick with high-temperature oxidation resistance and erosion resistance and preparation process of high-density silicon carbide brick

A high-temperature oxidation-resistant silicon carbide brick technology, applied in the field of high-temperature refractory materials, can solve problems such as the inability to solve the problem of long-term temperature resistance of silicon oxide, and achieve high-temperature service performance, good wear resistance, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

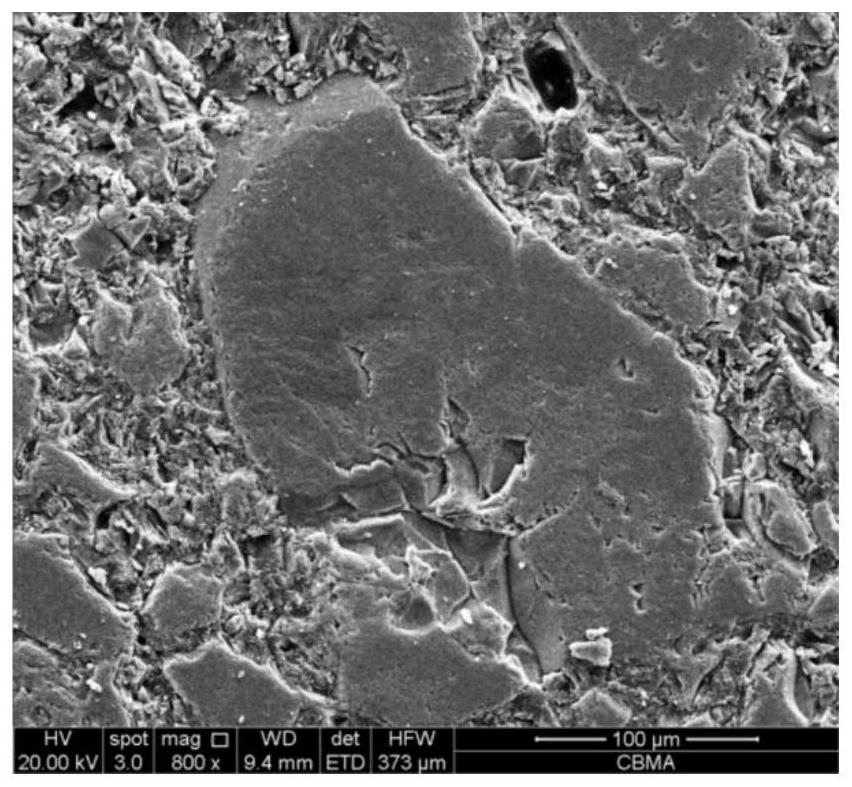

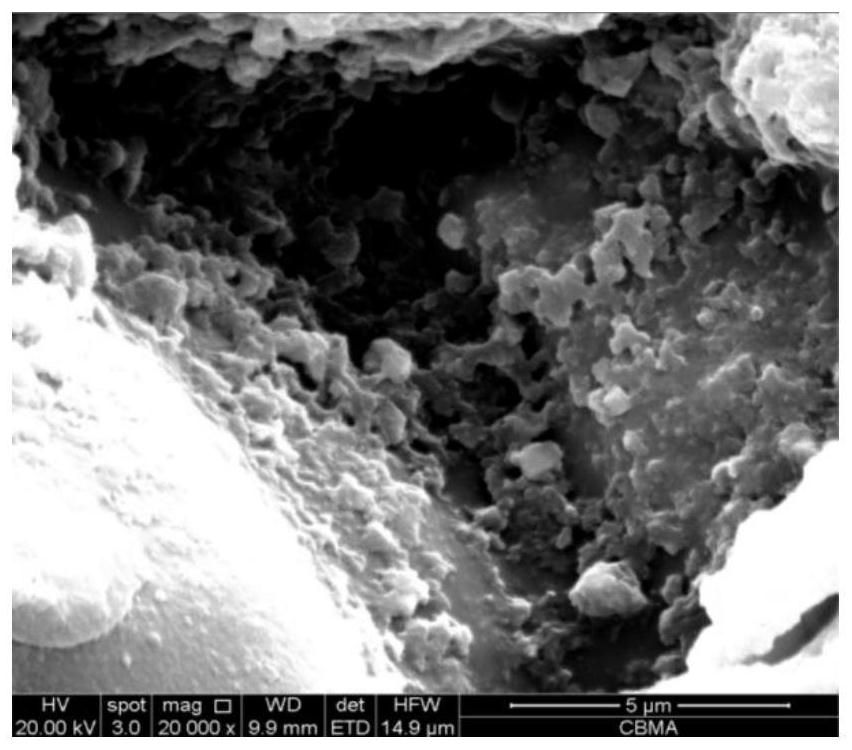

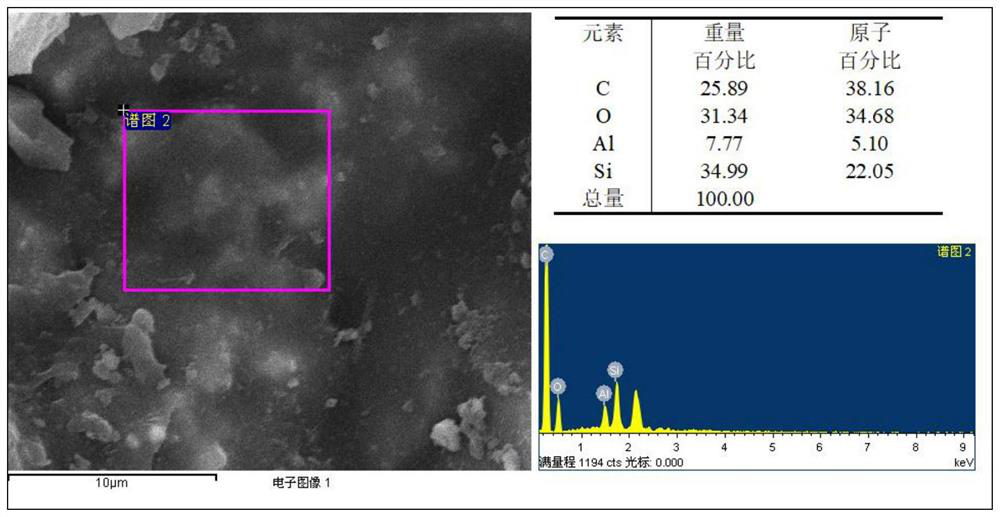

Image

Examples

Embodiment 1

[0037] High-density silicon carbide bricks with high-temperature oxidation resistance and corrosion resistance, the formula is calculated in parts by weight:

[0038] (1) Silicon carbide with a particle size of 5-3 mm, 10 parts;

[0039] (2) Silicon carbide with a particle size of 3-1 mm, 35 parts;

[0040] (3) Silicon carbide with a particle size of 1-0 mm, 30 parts;

[0041] (4) Silicon carbide with a particle size of 0.088-0.045 mm, 25 parts;

[0042] (5) Bentonite with particle size ≤0.045mm, 2 parts;

[0043] (6) bimodal alumina micropowder, 5 parts;

[0044] (7) Antioxidant (molar ratio of aluminum powder and nano silicon powder is 5:1), 1 part;

[0045] (8) silane coupling agent, 5 parts;

[0046] The particle size distribution characteristic of described bimodal aluminum oxide is: D 50 = 0.9 μm; D 90 = 2.5μm

[0047] The preparation process is as follows:

[0048] (1) Measure and prepare raw materials respectively according to the above formula;

[0049] (2) ...

Embodiment 2

[0055] High-density silicon carbide bricks with high-temperature oxidation resistance and corrosion resistance, the formula is calculated in parts by weight:

[0056] (1) Silicon carbide with a particle size of 5-3 mm, 15 parts;

[0057] (2) Silicon carbide with a particle size of 3-1 mm, 30 parts;

[0058] (3) Silicon carbide with a particle size of 1-0 mm, 25 parts;

[0059] (4) Silicon carbide with a particle size of 0.088-0.045 mm, 23 parts;

[0060] (5) Bentonite with particle size ≤ 0.045mm, 1.5 parts;

[0061] (6) bimodal alumina micropowder, 3 parts;

[0062] (7) Antioxidant (molar ratio of aluminum powder and nano silicon powder is 7:1), 3 parts;

[0063] (8) silane coupling agent, 3 parts;

[0064] The particle size distribution characteristic of described bimodal aluminum oxide is: D 50 = 0.7 μm; D 90 = 1.8μm

[0065] The preparation process of the high-temperature oxidation-resistant and corrosion-resistant high-density silicon carbide brick of the present ...

Embodiment 3

[0073] High-density silicon carbide bricks with high-temperature oxidation resistance and corrosion resistance, the formula is calculated in parts by weight:

[0074] (1) Silicon carbide with a particle size of 5-3 mm, 20 parts;

[0075] (2) Silicon carbide with a particle size of 3-1mm, 25 parts;

[0076] (3) Silicon carbide with a particle size of 1-0 mm, 20 parts;

[0077] (4) Silicon carbide with a particle size of 0.088-0.045 mm, 20 parts;

[0078] (5) Bentonite with particle size ≤0.045mm, 1 part;

[0079] (6) Bimodal alumina micropowder, 1 part;

[0080] (7) antioxidant (aluminum powder and nano-silicon powder molar ratio 10:1), 5 parts;

[0081] (8) silane coupling agent, 1 part;

[0082] The particle size distribution characteristic of described bimodal aluminum oxide is: D 50 = 0.5 μm; D 90 = 1.3μm

[0083] The preparation process of the high-temperature oxidation-resistant and corrosion-resistant high-density silicon carbide brick of the present invention is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com