Evaporating pipe

An evaporative tube and main tube technology, applied in the field of evaporative heat transfer tubes and heat transfer equipment, can solve the problem that the requirements of refrigeration equipment for the heat exchange performance of evaporators cannot be fully met, the improvement of heat exchange efficiency of heat transfer tubes is limited, and the reduction of pipe material The utilization rate of heat dissipation area and other issues can improve the heat exchange rate, increase the surface area, and increase the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above objects, features and advantages of the present invention more obvious, the technical contents of the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

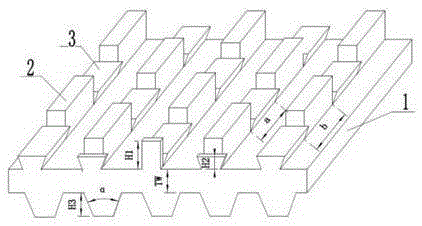

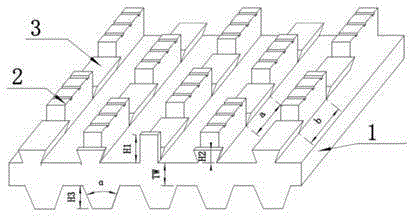

[0024] figure 1 It is an axonometric view of the first embodiment of the heat transfer enhanced evaporation tube of the present invention. As shown in the figure, the enhanced heat transfer evaporating tube of the present invention includes: a main tube 1 and fins 2 integrally formed with the main tube, and the fins 2 are arranged on the outer surface of the main tube in a manner of spirally coiling around the axis of the main tube , the fins include main fins 2 and auxiliary fins 3 that are continuously staggered along the length direction, wherein the height of the main fins 2 is greater than the height of the auxiliary fins 3; wherein, the main fins 2 and the axially adjacent The secondary fins 3 are adjoined or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com