Gallium and scandium co-doping zinc oxide scintillation single crystal and preparation method thereof

A technology of zinc oxide and single crystal, applied in the field of gallium scandium co-doped zinc oxide scintillation single crystal and its preparation, can solve the problems of matching photoelectric conversion components and stable load voltage, different magnitudes, etc., and achieve excellent crystal quality , high compatibility, good doping uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

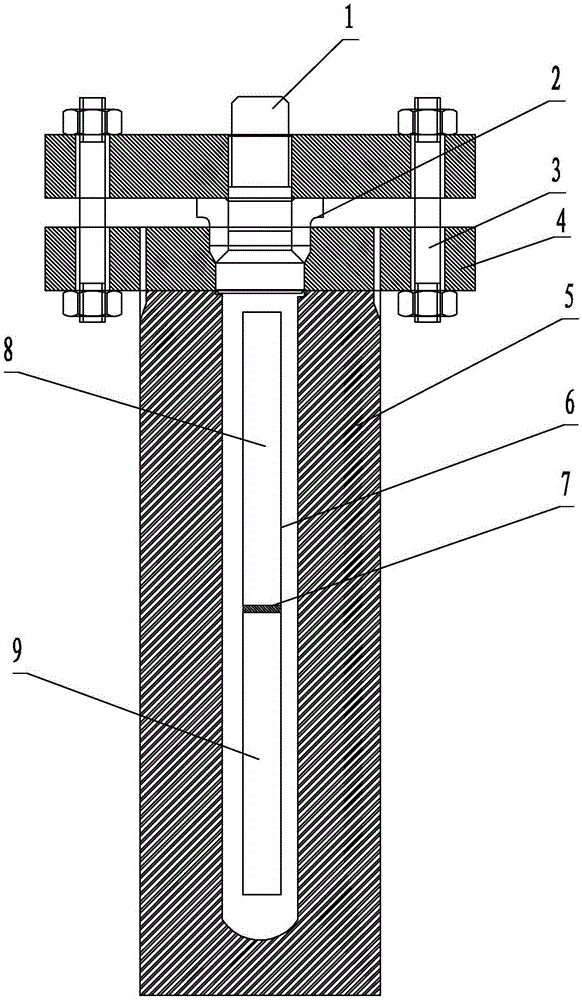

[0032] (1) Take 250g of zinc oxide as a raw material, after ultrasonic cleaning, dry in an oven at 80°C, and then place it at the bottom of the platinum liner;

[0033] (2) Add 0.014g of Ga to the bushing 2 o 3powder (accounting for 0.005mol% of zinc oxide raw material consumption);

[0034] (3) Add 0.105g of Sc to the bushing 2 o 3 Powder (accounting for 0.05mol% of zinc oxide raw material consumption);

[0035] (4) fill mineralizer by 80% filling degree in liner pipe, described mineralizer is the aqueous solution of KOH and LiOH, and in this mineralizer, the concentration of KOH is 4mol / L, and the concentration of LiOH is 0.1mol / L;

[0036] (5) Use a platinum wire to suspend the pure ZnO seed wafer whose seed orientation is the (0001) crystal plane under the top cover of the liner tube;

[0037] (6) Seal the liner pipe, put into the autoclave subsequently, fill 75% pure water between the liner pipe and the interlayer of the autoclave, then seal the autoclave;

[0038]...

Embodiment 2

[0046] (1) Weigh 120g of zinc oxide raw material, after ultrasonic cleaning, dry in an oven at 100°C, and then place it at the bottom of the platinum liner;

[0047] (2) Add 0.028g of GaCl to the bushing 3 powder (accounting for 0.02mol% of zinc oxide raw material consumption);

[0048] (3) Add 0.027g of Sc(NO 3 ) 3 Powder (accounting for 0.02mol% of zinc oxide raw material consumption)

[0049] (4) fill mineralizer by 65% filling degree in liner pipe, described mineralizer is the aqueous solution of KOH and LiOH, and in this mineralizer, the concentration of KOH is 4mol / L, and the concentration of LiOH is 0.1mol / L;

[0050] (5) Use a platinum wire to suspend the pure ZnO seed wafer whose seed orientation is the (0001) crystal plane under the top cover of the liner tube;

[0051] (6) seal liner pipe, put into autoclave subsequently, fill 65% pure water between the interlayer of liner pipe and autoclave, seal autoclave afterwards;

[0052] (7) Put the sealed autoclave i...

Embodiment 3

[0055] (1) Take 200g of zinc oxide as a raw material, after ultrasonic cleaning, dry in an oven at 80°C, and then place it at the bottom of the platinum liner;

[0056] (2) Add 0.0237g of Ga(OH) to the bushing tube 3 (accounting for 0.008mol% of zinc oxide raw material consumption);

[0057] (3) Add 0.0145g of ScN powder (accounting for 0.01mol% of zinc oxide raw material consumption) in the bushing tube

[0058] (4) Fill the liner pipe with a mineralizer at a filling degree of 50%. The mineralizer is an aqueous solution of KOH, and in the mineralizer, the concentration of KOH is 8mol / L;

[0059] (5) Use a platinum wire to suspend the pure ZnO seed wafer whose seed orientation is the (1010) crystal plane under the top cover of the liner tube;

[0060] (6) Seal the liner pipe, put into the autoclave subsequently, fill 50% pure water between the liner pipe and the interlayer of the autoclave, then seal the autoclave;

[0061] (7) Put the sealed autoclave in a two-stage resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com