Highly c-axis oriented aluminum nitride film and its preparation method and application

A film and orientation technology, applied in the field of high c-axis oriented aluminum nitride film and its preparation, can solve problems such as process compatibility, achieve the effects of low surface roughness, simple method and improved texture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

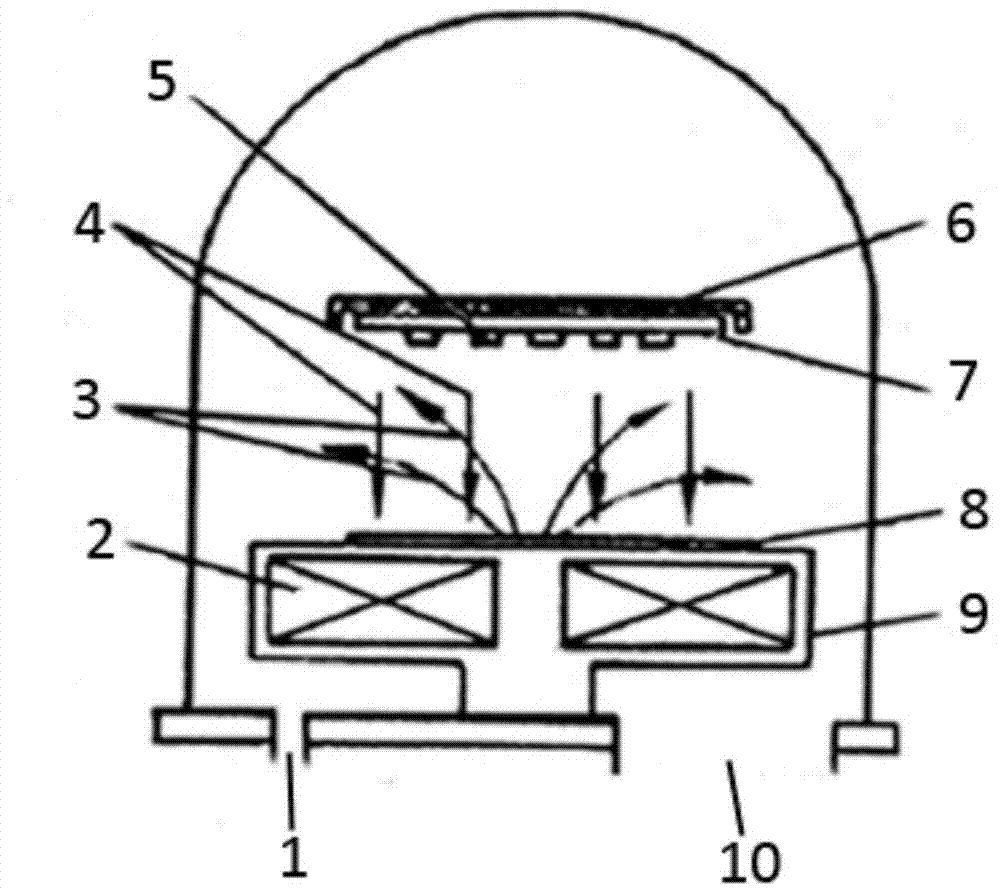

Method used

Image

Examples

Embodiment 1

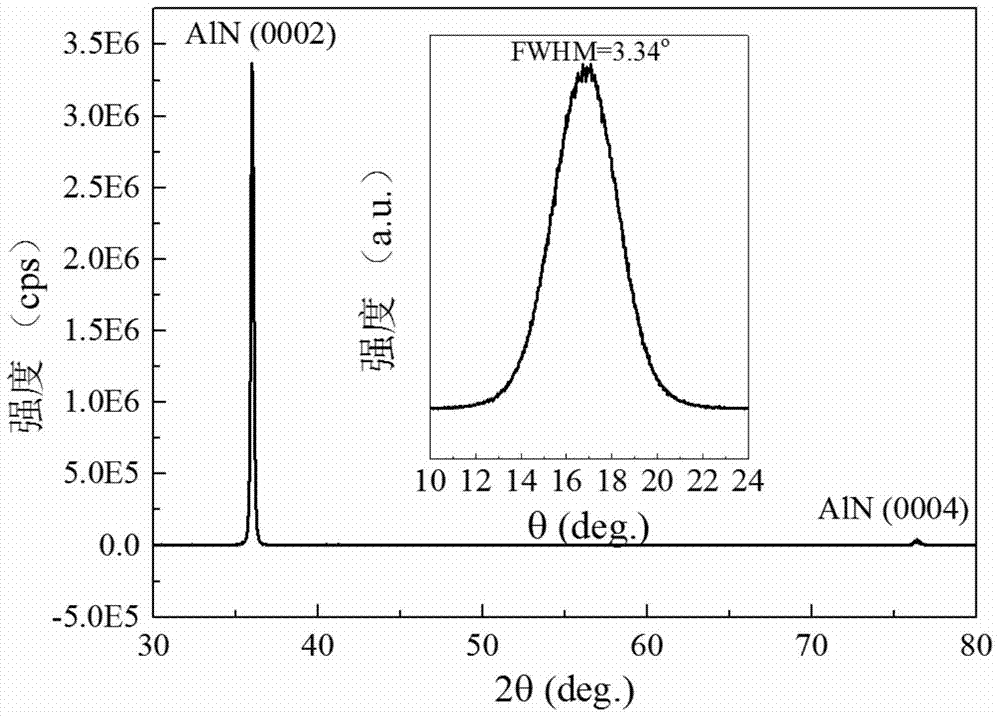

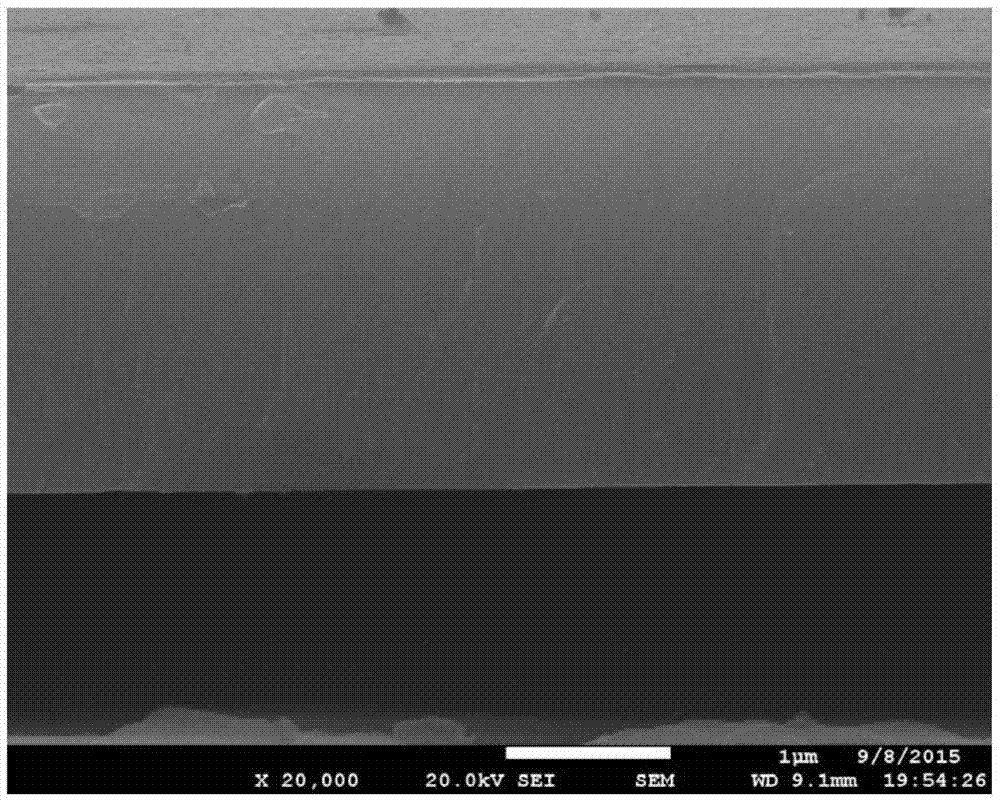

[0041] Example 1. Depositing a high c-axis orientation 2.5 μm aluminum nitride film on a polyimide substrate covered with a molybdenum disulfide buffer layer by DC reactive magnetron sputtering at room temperature

[0042] 1) A polyimide substrate with a thickness of 125 μm was bonded to a glass substrate, and then ultrasonically cleaned with acetone, alcohol and deionized water for 4 minutes respectively, and then dried with nitrogen. Put the flexible substrate-polyimide substrate that has been cleaned and dried on the glass substrate into the plasma etching machine, and vacuum the background to 10 -4 Below Pa. Refill high-purity argon to make the pressure of the whole system 10 -2 Pa, adjusting screen electrode voltage, accelerating voltage, anode voltage and cathode current are 710V, 100V, 60V and 12A, respectively. Open the baffle, etch with argon plasma for 5 minutes, let stand for more than 10 minutes after etching, fill with high-purity nitrogen, and take out the poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com