A kind of titanium alloy rotary part and its preparation method

A technology for titanium alloy and rotary parts, which is applied in the field of titanium alloy rotary parts and its preparation, can solve the problems of easy cracks in finished products, low texture strength, and poor toughness of finished products, and achieve simple and feasible preparation methods, good mechanical properties, and finished products. The effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a titanium alloy rotating part is characterized in that it is prepared according to the following steps:

[0035] (1) Pre-processing:

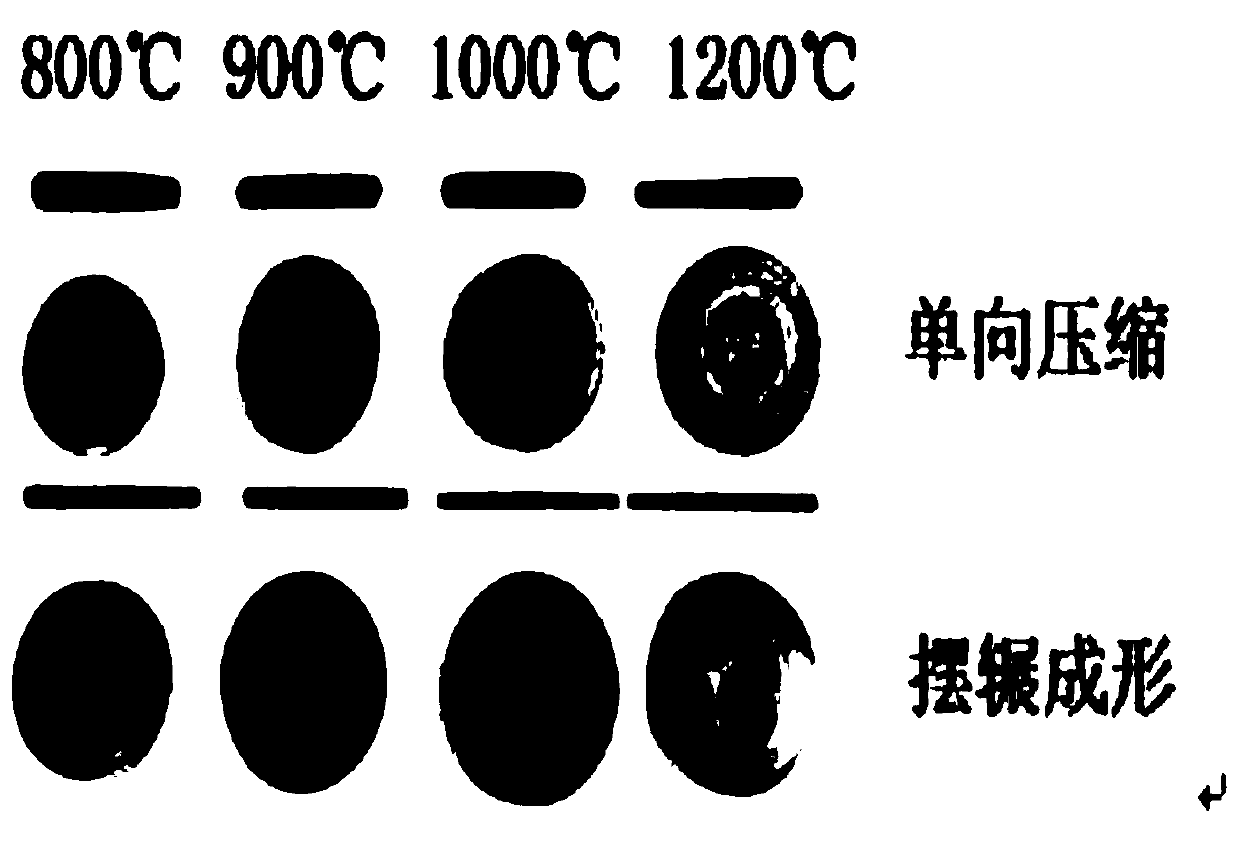

[0036] Put the TC4 titanium alloy cylindrical sample into a high-temperature box-type furnace, set the temperature at 800°C for heat preservation, take it out, and set aside; the size of the TC4 titanium alloy cylindrical sample is Φ32×42mm;

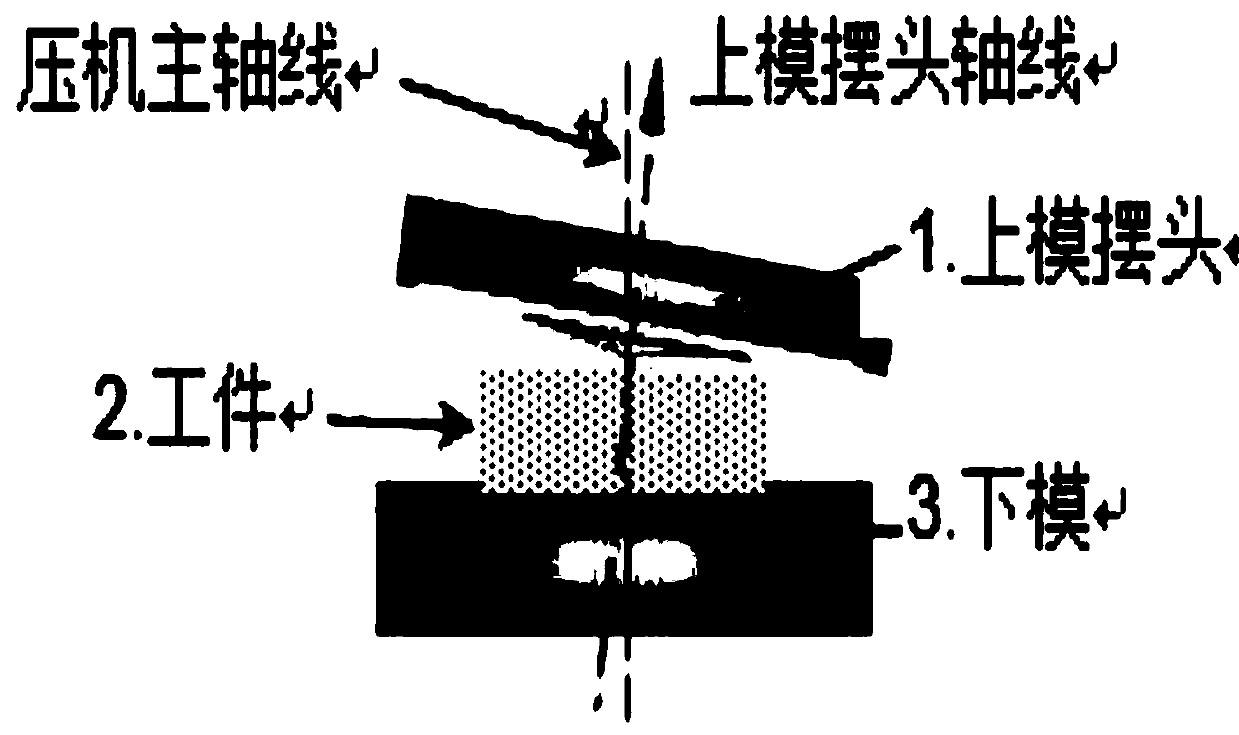

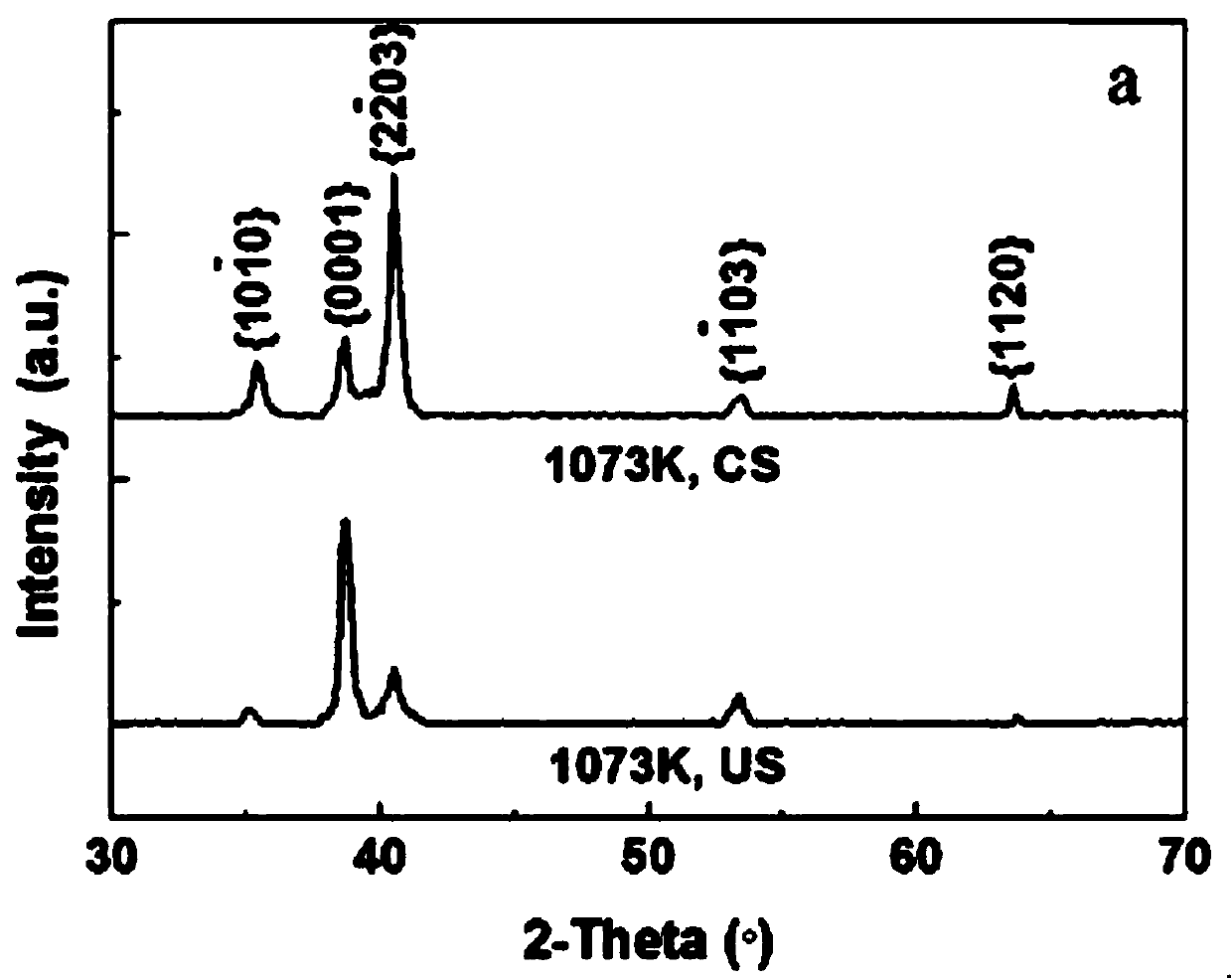

[0037] (2 swing rolling

[0038] Put the pretreated TC4 titanium alloy cylindrical sample in the pendulum mill, then add lubricant to the TC4 titanium alloy cylindrical sample, set the swing head speed to 190r / min, the pendulum mill angle to 2°, and press down vertically The speed is 8mm / s, and the end point of sample rolling is when the pressure of the press reaches 200T; the lubricant is composed of lard, graphite, molybdenum disulfide, boron nitride, and aluminum oxide, and its mass ratio is 89:5 :3:2:1.0; the mass ratio of the TC4 titanium alloy cylindrical sample to t...

Embodiment 2

[0049] A method for preparing a titanium alloy rotating part is characterized in that it is prepared according to the following steps:

[0050] (1) Pre-processing:

[0051] Put the TC4 titanium alloy cylindrical sample into a high-temperature box-type furnace, set the temperature at 900°C for 35 minutes, take it out, and set aside; the size of the TC4 titanium alloy cylindrical sample is Φ28×42mm;

[0052] (2 swing rolling

[0053] Put the pretreated TC4 titanium alloy cylindrical sample in the pendulum mill, then add lubricant to the TC4 titanium alloy cylindrical sample, set the swing head speed to 190r / min, the pendulum mill angle to 2°, and press down vertically The speed is 9mm / s, and the end point of sample rolling is when the pressure of the press reaches 200T; the lubricant is composed of lard, graphite, molybdenum disulfide, boron nitride, and aluminum oxide, and its mass ratio is 90:4 :4:3:1.0; the mass ratio of the TC4 titanium alloy cylindrical sample to the lubr...

Embodiment 3

[0058] A method for preparing a titanium alloy rotating part is characterized in that it is prepared according to the following steps:

[0059] (1) Pre-processing:

[0060] Put the TC4 titanium alloy cylindrical sample into a high-temperature box furnace, set the temperature at 1000°C for 5 minutes, take it out, and set it aside; the size of the TC4 titanium alloy cylindrical sample is Φ32×38mm;

[0061] (2 swing rolling

[0062] Put the pretreated TC4 titanium alloy cylindrical sample in the pendulum mill, then add lubricant to the TC4 titanium alloy cylindrical sample, set the swing head speed to 200r / min, the pendulum mill angle to 3°, press down vertically The speed is 8mm / s, and the end point of sample rolling is when the pressure of the press reaches 200T; the lubricant is composed of lard, graphite, molybdenum disulfide, boron nitride, and aluminum oxide, and its mass ratio is 87:6 :2:3:0.9; the mass ratio of the TC4 titanium alloy cylindrical sample to the lubricant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com