Method for depositing high c-axis orientation aluminum nitride film on flexible substrate

A flexible substrate, aluminum nitride technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problem of weak surface bonding force, to improve mechanical bonding force, increase texture strength, The effect of increasing the roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

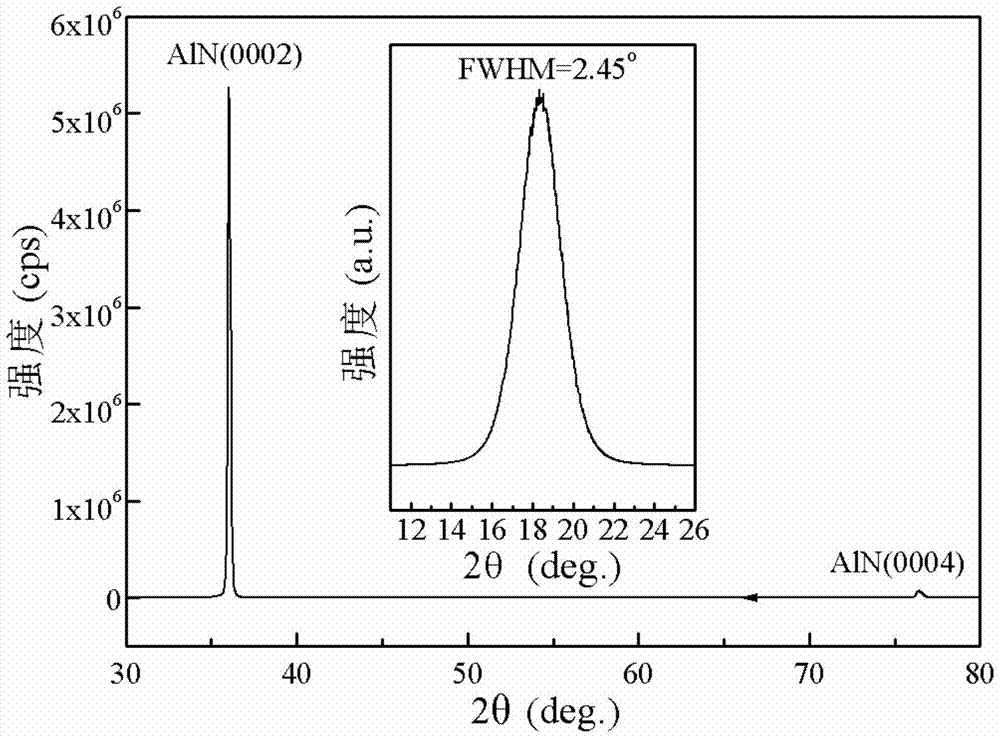

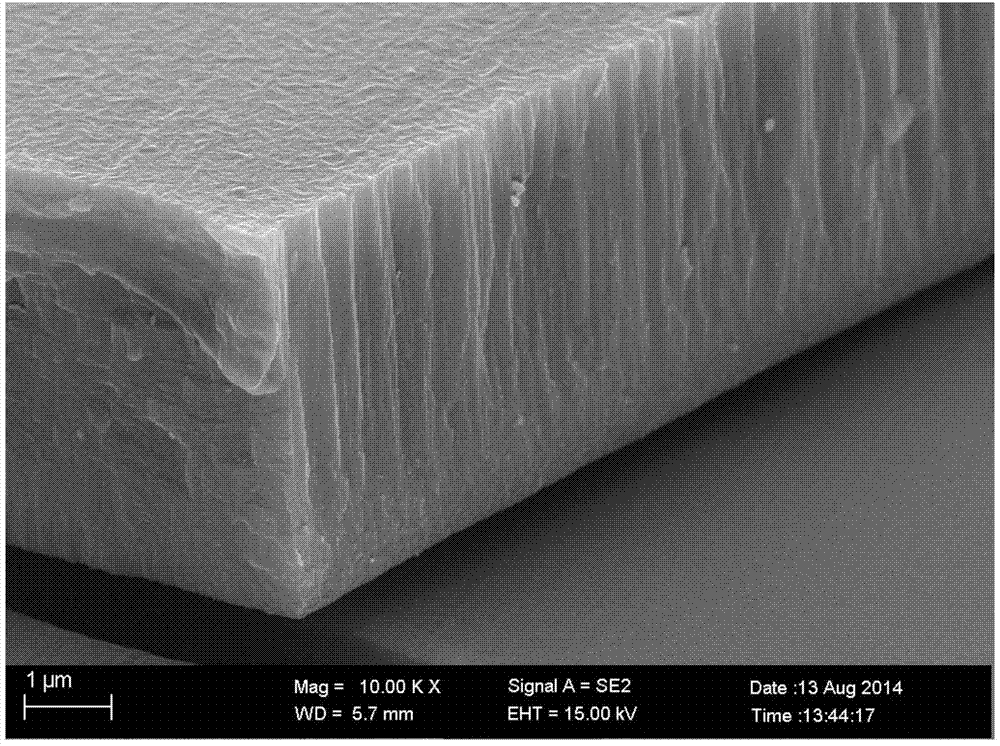

[0036] Example 1. Deposition of a high c-axis orientation 5 μm aluminum nitride film on a polyimide substrate by DC reactive magnetron sputtering at room temperature

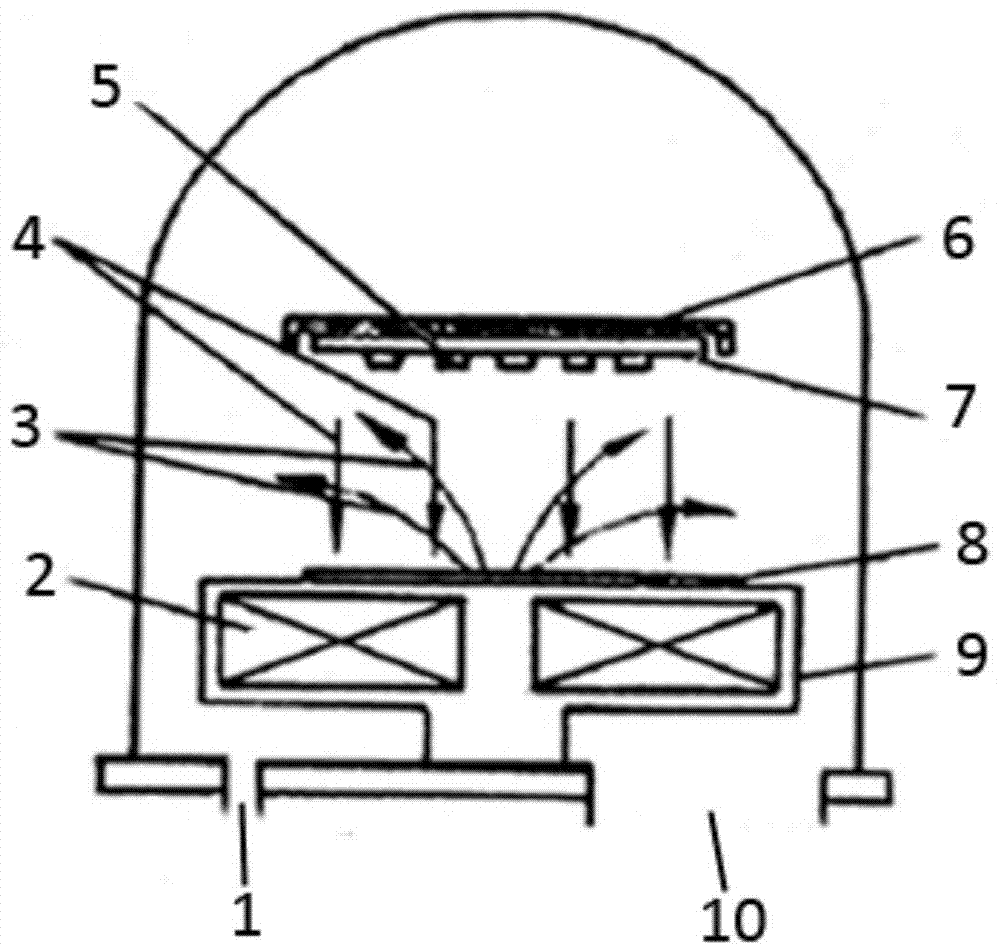

[0037] 1) The polyimide substrate was glued on the glass substrate, and then ultrasonically cleaned with acetone, alcohol and deionized water for 4 minutes respectively, and then dried with nitrogen. Put the flexible substrate-polyimide substrate that has been cleaned and dried on the glass substrate into the plasma etching machine, and vacuum the background to 10 -4 Below Pa. Refill high-purity argon to make the pressure of the whole system 10 -2 Pa, adjusting screen electrode voltage, accelerating voltage, anode voltage, and cathode current are 710V, 100V, 60V, and 12A, respectively. Open the baffle, etch with argon plasma for 5 minutes, let stand for more than 10 minutes after etching, fill with high-purity nitrogen, and take out the polyimide substrate etched with argon plasma.

[0038] 2) Fix the plasma-...

Embodiment 2

[0047] Example 2. Deposition of a high c-axis orientation 2 μm aluminum nitride film on a polyimide substrate by room temperature DC reactive magnetron sputtering

[0048] 1) The polyimide substrate was glued on the glass substrate, and then ultrasonically cleaned with acetone, alcohol and deionized water for 4 minutes respectively, and then dried with nitrogen. Put the flexible substrate-polyimide substrate that has been cleaned and dried on the glass substrate into the plasma etching machine, and vacuum the background to 10 -4 Below Pa. Refill high-purity argon to make the pressure of the whole system 10 -2 Pa, adjusting screen electrode voltage, accelerating voltage, anode voltage, and cathode current are 710V, 100V, 60V, and 12A, respectively. Open the baffle, etch with argon plasma for 5 minutes, let stand for more than 10 minutes after etching, fill with high-purity nitrogen, and take out the polyimide substrate etched with argon plasma.

[0049] 2) Fix the plasma-etc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com