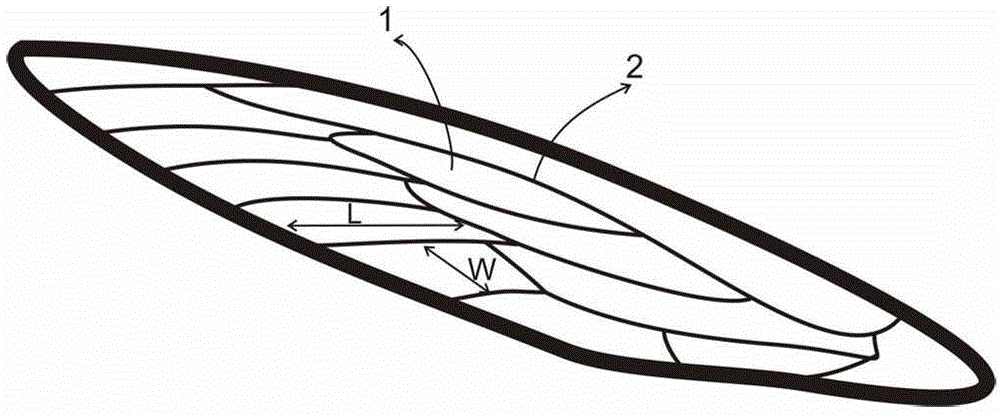

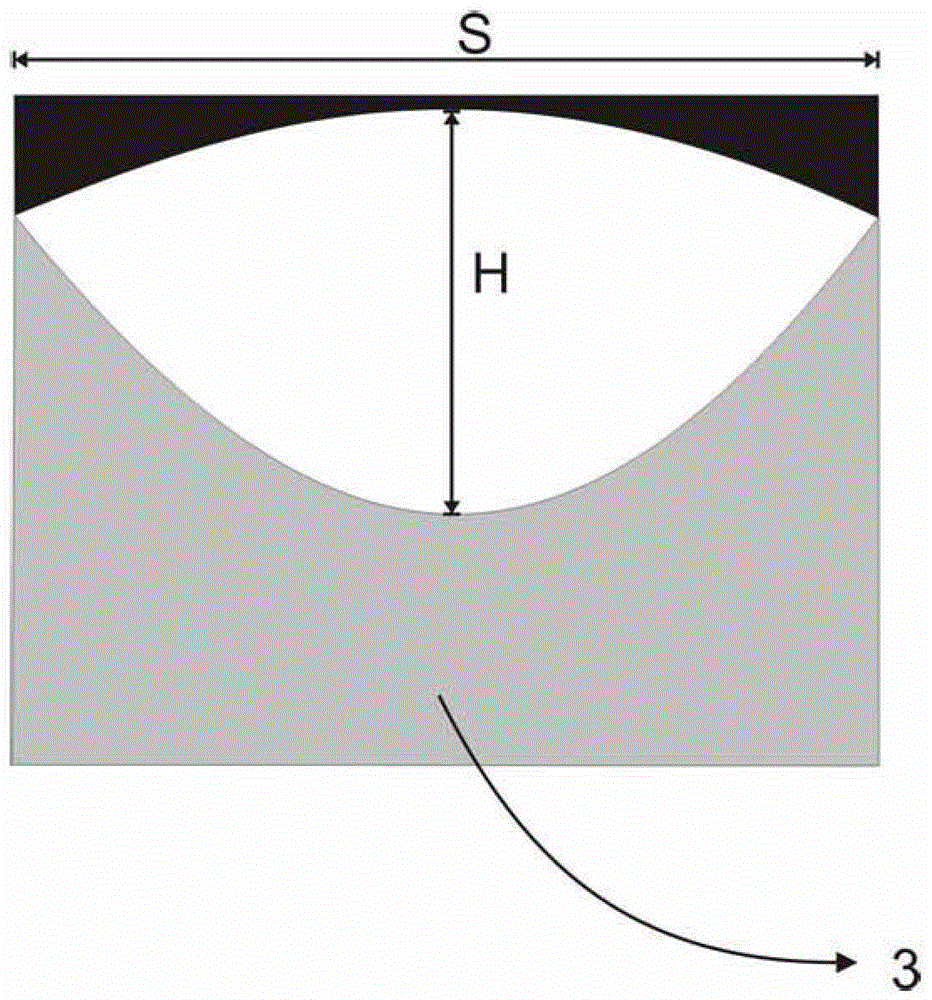

Laser wire-filling local bionic-texture manufacturing method and equipment for metal functional surfaces

A laser wire filling and functional technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, to achieve the effect of improving strength and toughness, overcoming limitations, and improving preparation quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described with the implementation provided in conjunction with the accompanying drawings. The present invention is described in detail below:

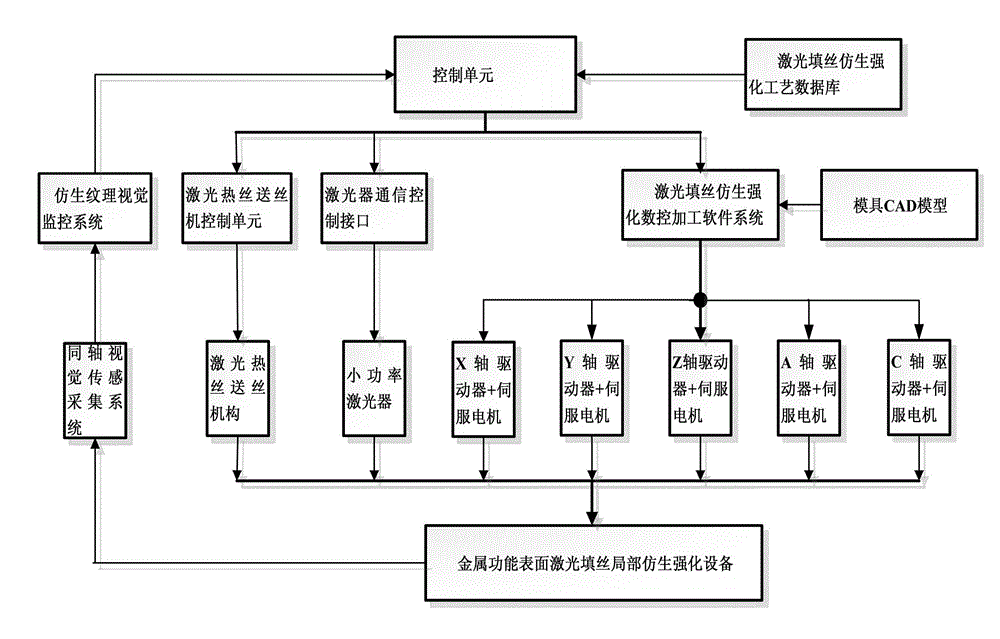

[0023] The metal functional surface laser wire filling partial bionic strengthening equipment is composed of a control unit, a vision system, an adjustable temperature hot wire feeder, a laser and a five-degree-of-freedom numerical control workbench. Its overall structure is shown in the attachment. Figure 4 , which are described in detail below.

[0024] The control unit and the control unit include an industrial control computer, which has a laser wire filling bionic strengthening process module and a numerical control processing module.

[0025] The first part of the "laser wire filling bionic strengthening process module" is the processing parameter database, which is the result of summarizing and optimizing a large number of experimental data. Each data record in the database include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com