Glass cutting fluid

A cutting fluid and glass technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor glass powder settling, poor grinding-assistance durability, poor lubrication and cooling effect, etc., to achieve good lubricity, prolonged The effect of improving the service life and cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

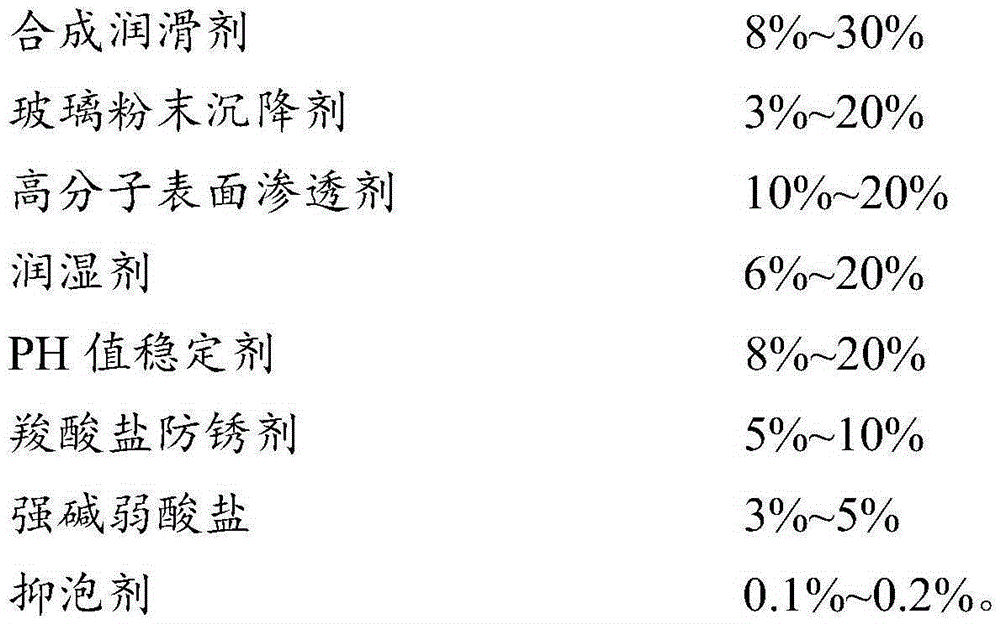

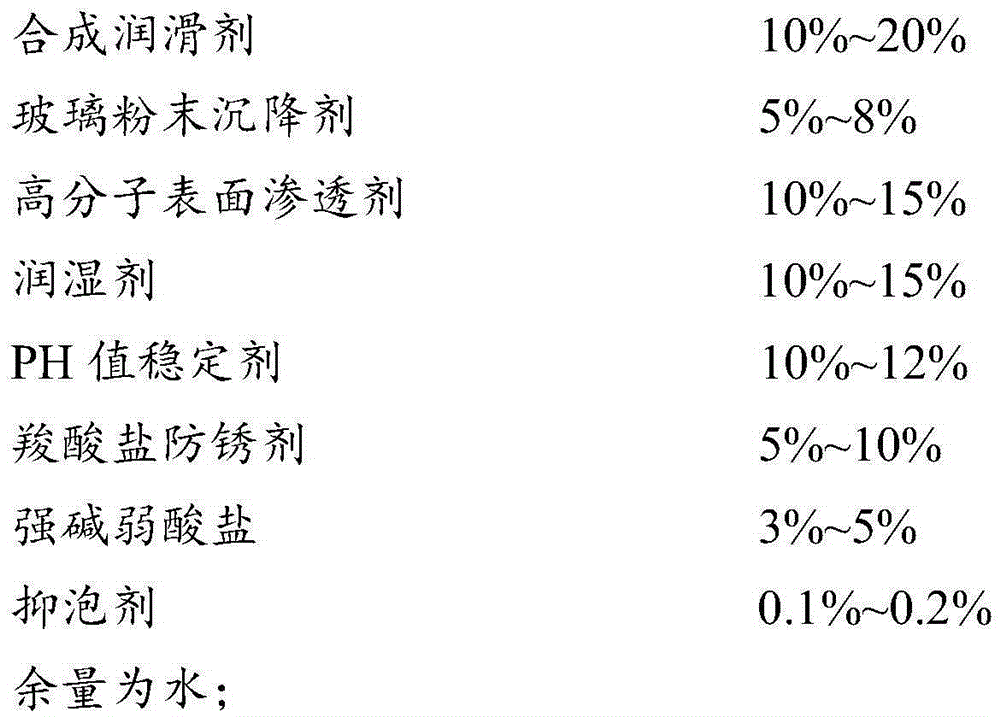

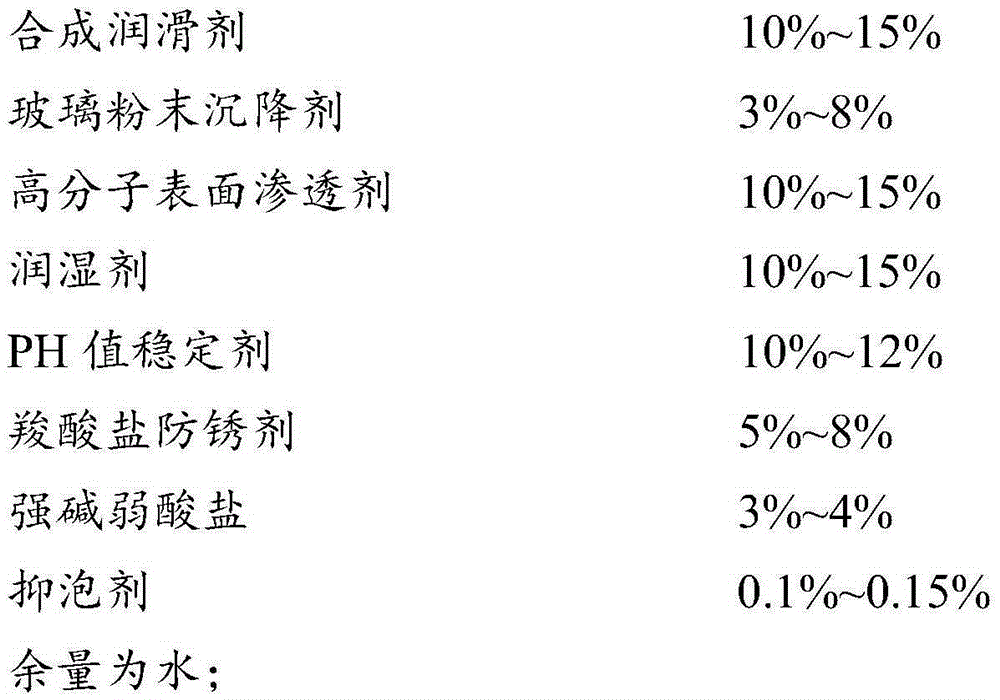

Method used

Image

Examples

preparation example Construction

[0046]The present invention also provides a method for preparing glass cutting fluid. In a preferred embodiment, the method for preparing glass cutting fluid includes the following steps:

[0047] Provide the proportioning of the glass cutting fluid of the above-mentioned preferred embodiment;

[0048] Add C4-C12 organic carboxylic acid rust inhibitor, synthetic lubricant, polymer surface penetrating agent, dipropylene glycol wetting agent, PH value stabilizer, strong alkali and weak acid salt, antifoam agent and glass powder sedimentation agent to prepare a mixed solution;

[0049] The mixture is heated to 60°C-70°C, stirred for 2-3 hours, and then filtered and packaged with a 5um filter bag.

Embodiment 1

[0052] The proportion of glass cutting fluid is as follows:

[0053] C4~C12 organic carboxylate 7.5%, PH value stabilizer 10%, polymer surface penetrant 12%, dipropylene glycol 12%, synthetic lubricant 12.5%, strong base and weak acid salt 3%, foam inhibitor 0.1%, 3% of the glass powder sedimentation agent and the balance are water;

[0054] The preparation process of the glass cutting fluid is as follows:

[0055] In the reaction kettle filled with water, add the above-mentioned components in sequence according to the above-mentioned order to prepare a mixed solution;

[0056] Heat the mixture to 60°C and stir for 2-3 hours;

[0057] Sampling and testing of various indicators, filtering and packaging after passing the test.

[0058] The product specifications of the glass cutting fluid are as follows:

[0059] Appearance is light yellow transparent liquid; almost odorless; good physical stability, no stratification or crystallization at 5±2°C, no stratification at 60±2°C;...

Embodiment 2

[0061] The ratio of cutting fluid is as follows:

[0062] C4~C12 organic carboxylate 6.5%, PH value stabilizer 10%, polymer surface penetrant 10%, dipropylene glycol 6%, synthetic lubricant 8%, strong base and weak acid salt 3%, foam inhibitor 0.1%, 3% of the glass powder sedimentation agent and the balance are water;

[0063] The preparation process of the glass cutting fluid is as follows:

[0064] In the reaction kettle filled with water, add the above-mentioned components in sequence according to the above-mentioned order to prepare a mixed solution;

[0065] Heat the mixture to 60°C and stir for 2-3 hours;

[0066] Sampling and testing of various indicators, filtering and packaging after passing the test.

[0067] The product specifications of the glass cutting fluid are as follows:

[0068] Appearance is light yellow transparent liquid; almost odorless; good physical stability, no stratification or crystallization at 5±2°C, no stratification at 60±2°C; effective cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com