Epoxy resin material with strong corrosion resistance and method for preparing integral core-penetrating plate by using same

An epoxy resin matrix, epoxy resin technology, applied in the field of building materials, can solve the problems of deformation of the entire table, the basic material can not be anti-corrosion, time-consuming, labor-intensive and financial-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

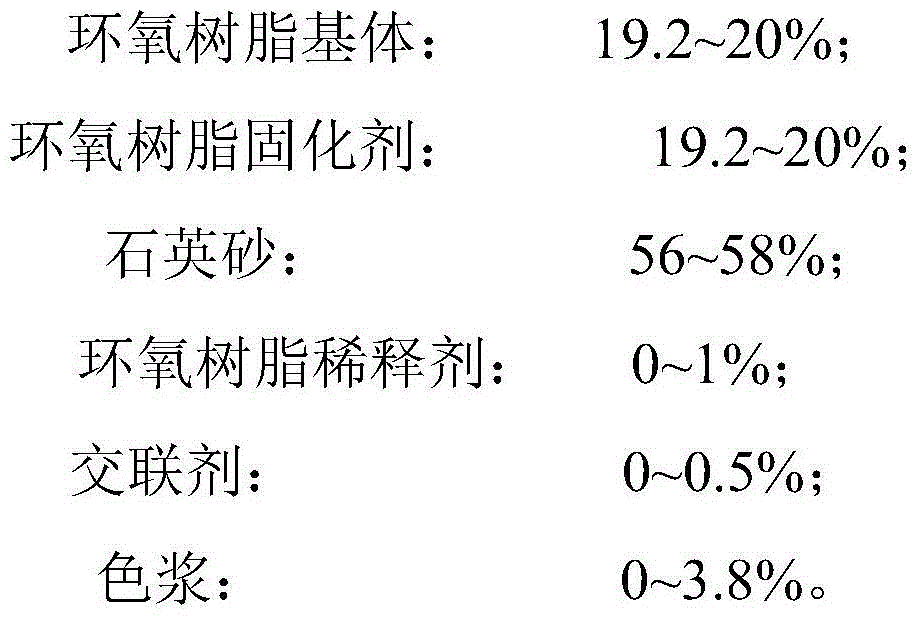

[0031] Embodiment 1 A method for preparing an epoxy resin integrated through-core board, comprising the following steps:

[0032] Step 1. Stir and preheat 19.2 parts of bisphenol A epoxy resin matrix, 20 parts of epoxy resin curing agent triethylamine and 58 parts of 500-mesh quartz sand at a speed of 65-75 rpm to 75-85°C , 80~85℃, 65~75℃, standby;

[0033] Step 2. Put the preheated bisphenol A epoxy resin matrix into the reaction kettle preheated to 70-80°C, add the preheated quartz sand, stir for 1-2 hours, and then put in the preheated triethylamine amine;

[0034] Step 3, after stirring the mixture obtained in Step 2 for 1 to 2 hours, put in 1 part of epoxy resin thinner toluene and 1.3 parts of red color paste;

[0035] Step 4. After stirring the mixture obtained in the previous step for 0.2-1 hour, put in 0.5 parts of silane coupling agent, react for 10-30 minutes and pour it into a mold preheated to 100-130°C while it is hot, heat insulation and raise the temperature ...

Embodiment 2

[0036] Embodiment 2 A method for preparing an epoxy resin integrated through-core board, comprising the following steps:

[0037] Step 1. Stir and preheat 20 parts of brominated bisphenol A epoxy resin matrix, 19.2 parts of epoxy resin curing agent boron trifluoride and 56 parts of 400-mesh quartz sand at a speed of 65 to 75 rpm to 75 ~85℃, 80~85℃, 65~75℃, standby;

[0038] Step 2. Put the preheated brominated bisphenol A epoxy resin matrix into the reaction kettle preheated to 70-80°C, add half the weight of the preheated quartz sand, stir for 1-2 hours, and then put it into the preheated The final epoxy resin curing agent boron trifluoride and the remaining quartz sand;

[0039] Step 3, after stirring the mixture obtained in Step 2 for 1 to 2 hours, put in 0.5 parts of epoxy resin diluent xylene and 3.8 parts of black color paste;

[0040] Step 4. After stirring the mixture obtained in Step 3 for 0.2-1 hour, put in 0.5 parts of silane coupling agent, react for 10-30 minute...

Embodiment 3

[0049] Embodiment 3 A method for preparing an epoxy resin integrated through-core board, comprising the following steps:

[0050] Step 1, 9.2 parts of bisphenol A epoxy resin matrix, 10 parts of brominated bisphenol A epoxy resin matrix, 20 parts of epoxy resin curing agent acetic anhydride and 56 parts of 600-mesh quartz sand at 65 to 75 rpm Stir and preheat to 75-85°C, 80-85°C, 65-75°C at a certain speed, and set aside;

[0051] Step 2. Put the preheated bisphenol A epoxy resin matrix and brominated bisphenol A epoxy resin matrix into a reaction kettle preheated to 70-80°C, add half the weight of preheated quartz sand, and stir After 1 to 2 hours, put in the preheated epoxy resin curing agent m-phenylenediamine and the remaining quartz sand;

[0052] Step 3. After stirring the mixture obtained in the previous step for 1 to 2 hours, put in 1 part of epoxy resin diluent ethyl acetate and 3.3 parts of blue color paste;

[0053] Step 4. After stirring the mixture obtained in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com