A method for removing soluble organic matter and heavy metal ions in electroplating wastewater

A technology for heavy metal ions and electroplating wastewater, applied in chemical instruments and methods, water pollutants, metallurgical wastewater treatment, etc. Adjustable functions and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

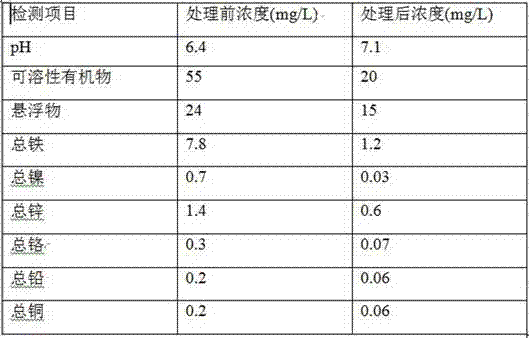

[0020] The treatment process of wastewater from an electroplating factory in Guangdong is as follows:

[0021] The electroplating wastewater first enters the pH adjustment tank, the influent pH is 6.5, the aspect ratio of the adjustment tank is 1.5, the residence time is 15 minutes, and the average flow rate is 7 m / s. Industrial calcium hydroxide is added to the pH adjustment tank to adjust the electroplating wastewater. The pool is equipped with a pH meter and an automatic control system to control the pH value of the effluent at 7.7. Then the electroplating wastewater enters the packing tower for removing soluble organic matter and heavy metal ions through the lifting pump. The main function of the packing tower is to remove organic pollutants such as soluble organic matter and inorganic pollutants such as various heavy metal ions in the electroplating wastewater. The packed packed tower is a closed cylinder. The height-to-diameter ratio of the cylinder is 20:1, and the res...

Embodiment 2

[0027] The treatment process of wastewater from an electroplating factory in Jiangsu is as follows:

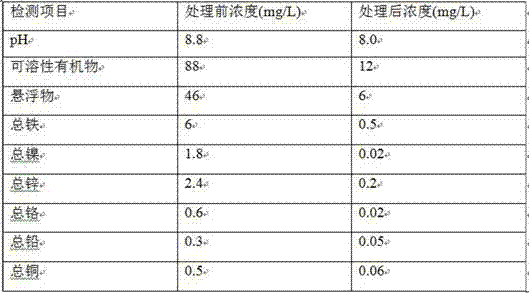

[0028] The electroplating wastewater first enters the pH adjustment tank, the pH of the influent water is 8.7, the aspect ratio of the adjustment tank is 1.4, the residence time is 10 minutes, and the average flow rate is 7 m / s. Industrial sulfuric acid is added to the pH adjustment tank to adjust the electroplating wastewater. Equipped with a pH meter and an automatic control system to control the pH value of the effluent to 7.9. Then the electroplating wastewater enters the packing tower for removing soluble organic matter and heavy metal ions through the lifting pump. The main function of the packing tower is to remove organic pollutants such as soluble organic matter and inorganic pollutants such as various heavy metal ions in the electroplating wastewater. The packed packed tower is a closed cylinder. The height-to-diameter ratio of the cylinder is 15:1, and the residenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com