A method for removing phosphorus in waste water by using fly ash

A waste water and coal powder ash technology, applied in the environmental field, can solve problems such as difficult dehydration, difficult treatment, and high cost of phosphorus removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

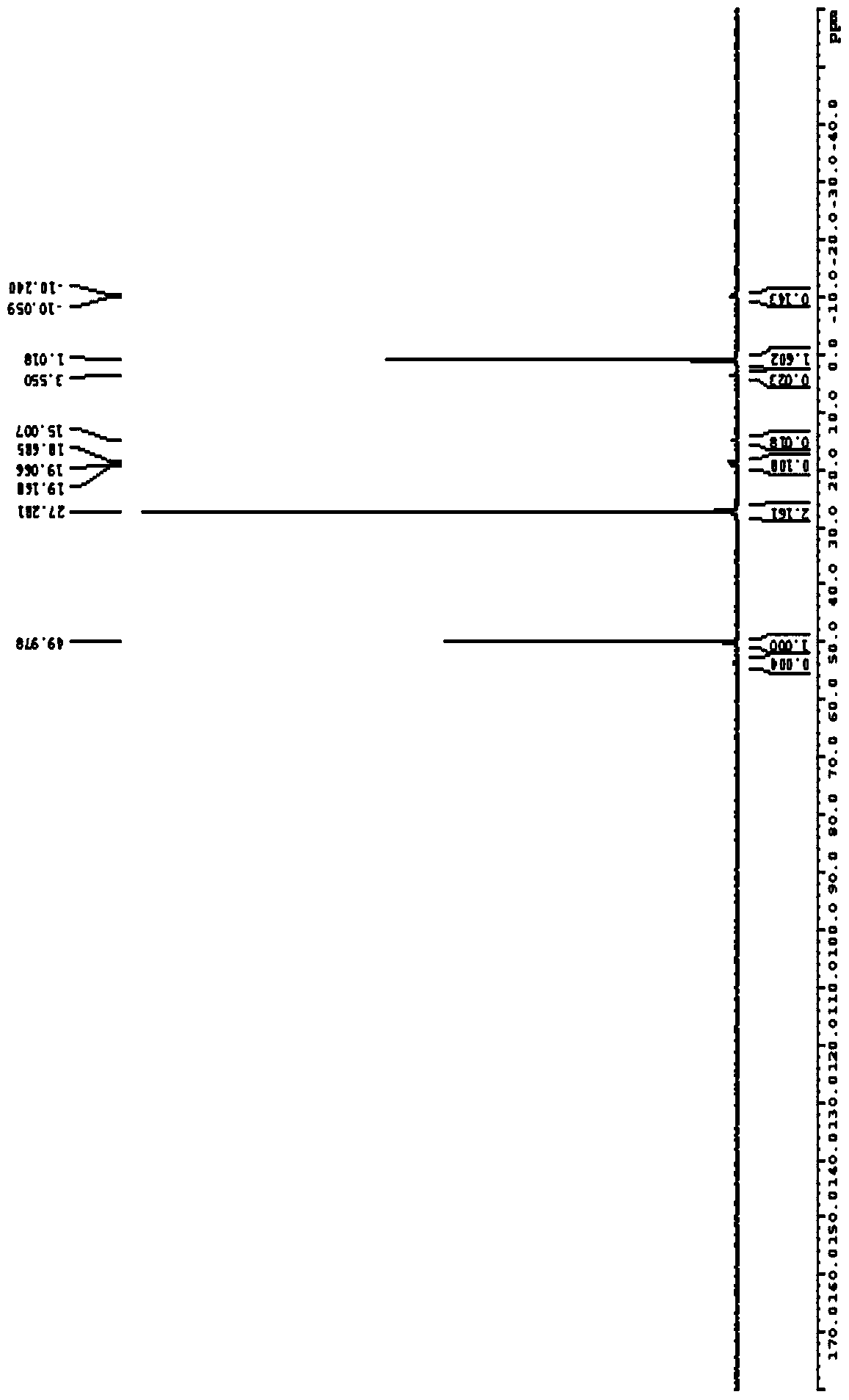

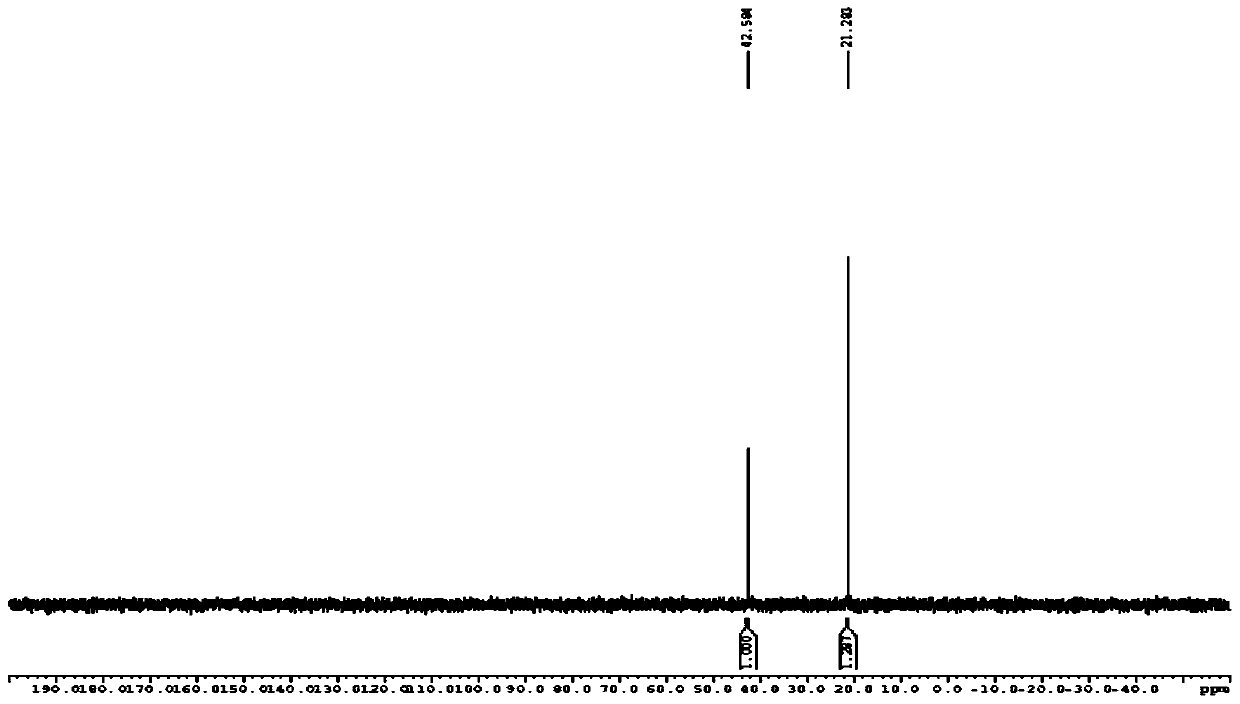

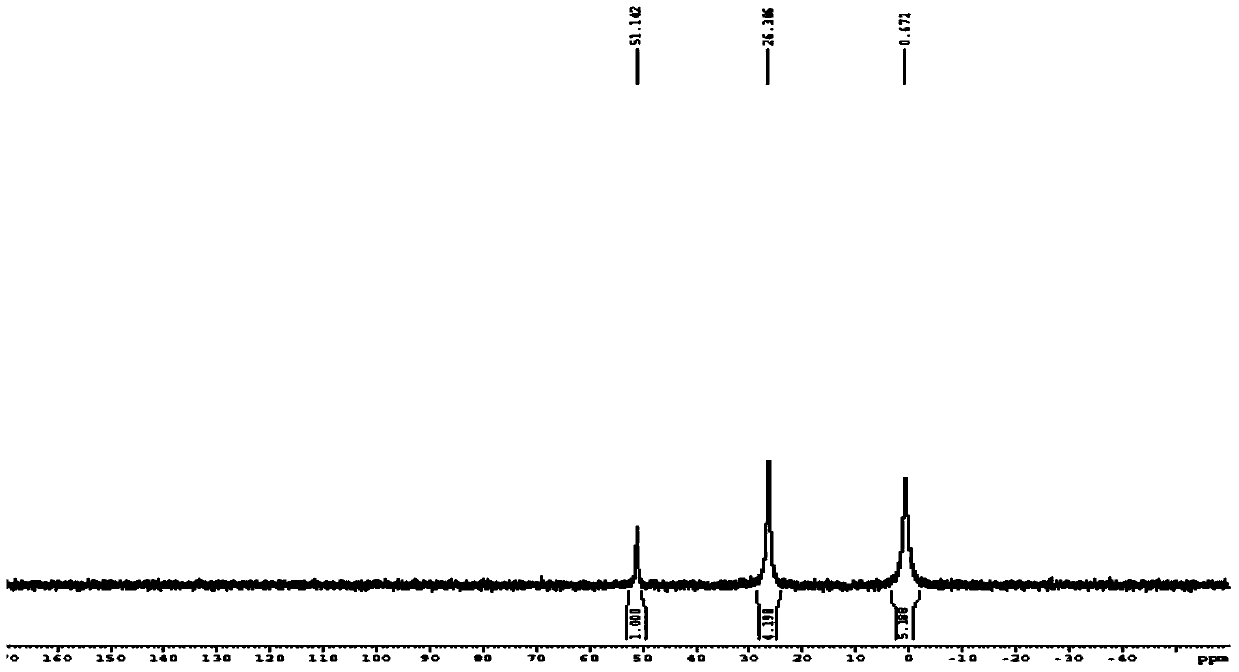

Image

Examples

Embodiment 1

[0033] Example 1 (Example 1 is used to illustrate that the method provided by the invention is also applicable to inorganic phosphorus.)

[0034] (1) Take 200 mL of simulated wastewater prepared with sodium dihydrogen phosphate at a concentration of 5000 mg / L (calculated as P) into a 250 mL Erlenmeyer flask, and adjust the pH of the wastewater to 6.0 with 2 mol / L hydrochloric acid.

[0035] (2) Add quantitatively 30g of coal powder ash with a calcium oxide content of 25%, the mass ratio of coal powder ash to waste water is 3:20, and react at a constant temperature of 55°C for 1 hour under magnetic stirring (300 rpm).

[0036] (3) Separation of waste water and coal dust after the reaction. Filter with Whatman No1# filter paper, adopt plasma emission spectrometry (ICP) and pH meter to test the total phosphorus and pH value in the filtrate, and its total phosphorus content is 51mg / L, and pH is 12.29. Phosphorus removal efficiency reaches 99.0%. The experimental results show tha...

Embodiment 2

[0038] (1) Take 200 mL of simulated wastewater prepared with methylphosphonic acid at a concentration of 2155 mg / L (calculated as P) into a 250 mL Erlenmeyer flask, and adjust the pH of the wastewater to 6.8 with 20% sodium hydroxide.

[0039] (2) Add quantitatively 15g of coal powder ash with a calcium oxide content of 25%, the mass ratio of coal powder ash to waste water is 3:40, and react at a constant temperature of 55°C for 1 hour under magnetic stirring (300 rpm).

[0040] (3) Separation of waste water and coal dust after the reaction. Filter with Whatman No1# filter paper, adopt plasma emission spectrometry (ICP) and pH meter to test the total phosphorus and pH value in the filtrate, and its total phosphorus content is 93mg / L, and pH is 12.08. Phosphorus removal efficiency reaches 95.7%. The experimental results show that coal fly ash not only has a strong chemical adsorption effect on orthophosphorus, but also has a strong removal effect on organic phosphorus.

Embodiment 3

[0042] Get industrial waste water, through ion chromatographic analysis, total phosphorus (calculated as P) in water is 155mg / L, wherein contains 63.3% orthophosphorus, 36.7% organic phosphorus. The organic phosphorus content in the form of methylphosphonic acid was 43.5mg / L (accounting for 76.5% of organic phosphorus), and the content of organic phosphorus in the form of dimethylphosphonic acid was 13.4mg / L (accounting for 23.5% of total organic phosphorus).

[0043] (1) Take the above-mentioned 200mL industrial wastewater into a 250mL Erlenmeyer flask, and adjust the pH of the wastewater to 6.5 with 20% sodium hydroxide.

[0044] (2) Add quantitatively 7.5g of coal powder ash with a calcium oxide content of 25%, the mass ratio of coal powder ash to waste water is 3:80, and react at a constant temperature of 55°C for 1 hour under magnetic stirring (300 rpm).

[0045] (3) Separation of waste water and coal dust after the reaction. Filter with Whatman No1# filter paper, use plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com