Rotating type flaw detection injection molding machine die

An injection molding machine and rotary technology, which is applied in the field of rotary flaw detection injection molding machine molds, can solve the problems of insufficient mold filling, large flow resistance, and inability of the melt to continue to flow, and achieves simple structure, improved qualification rate, and increased fluidity. and dispersive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

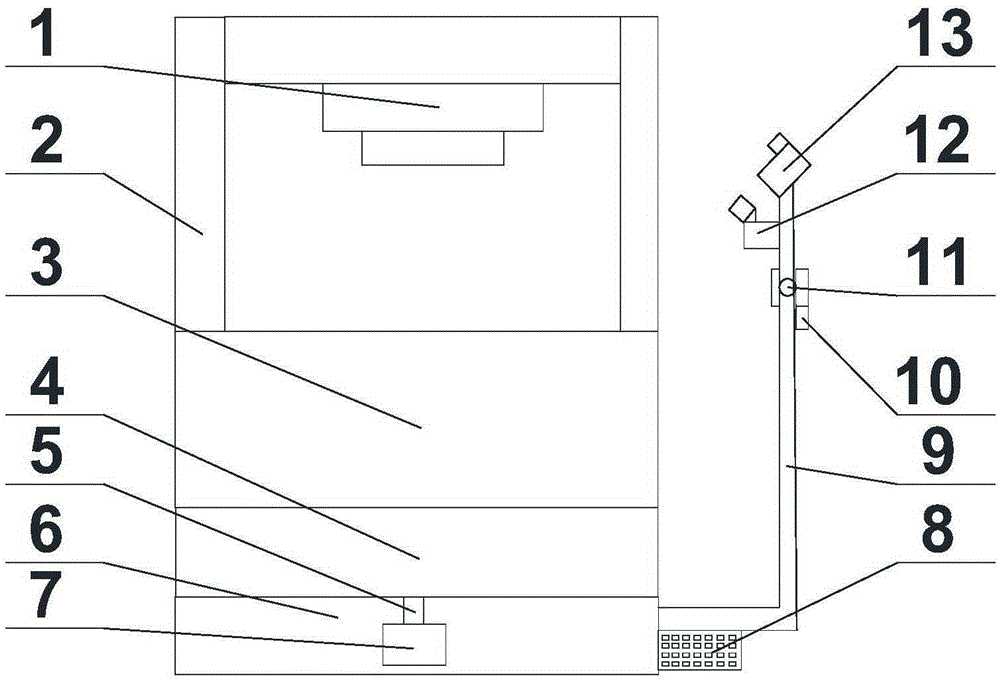

[0017] like figure 1 As shown, a mold for a rotary flaw detection injection molding machine includes a movable mold part 1, a fixed mold part 3, a rotating base 4, a supporting box 6, a main controller 8, a frame 9, a stepping motor 10, a rotating shaft 11, Electromagnetic flaw detector 12, industrial camera 13 and rotary motor 7, two push-pull rods 2 are installed between the movable mold part and the fixed mold part, and the two push-pull rods are respectively symmetrically installed on the left and right sides of the movable mold part and the fixed mold part , wherein the push-pull rod is an electric push-pull rod. The bottom of the fixed mold part is equipped with a rotating base, and the bottom of the rotating base is equipped with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com