Magnetic polystyrene foam and preparation method and application thereof

A polystyrene foam, magnetic technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of incompatibility, low recycling efficiency, difficult recycling, etc. Falling off, good adsorption effect, the effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

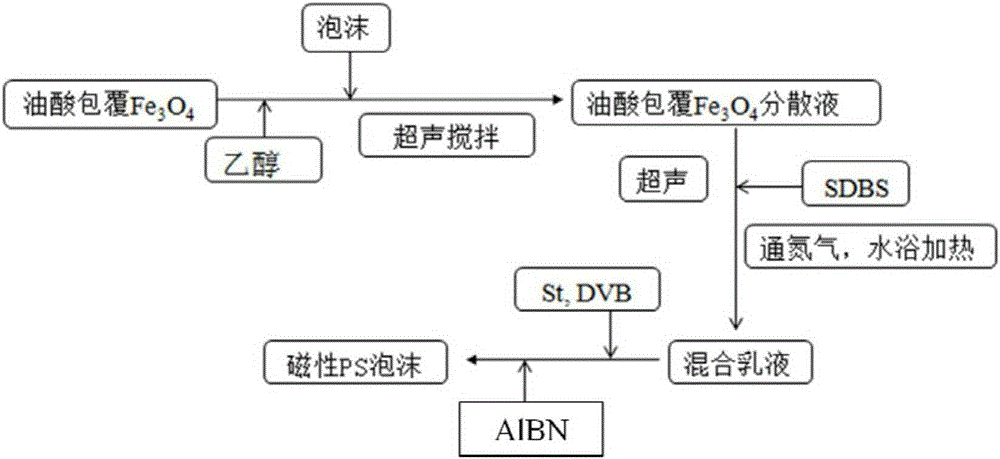

[0023] A kind of preparation method of magnetic polystyrene foam of the present invention, concrete preparation process is as follows figure 1 , including the following steps:

[0024] Step 1, Fe 3 o 4 Deionized aqueous solution, sonicated at 25-35°C for 10-20 minutes to form Fe 3 o 4 Dispersions;

[0025] Step 2, adding the trimmed clean foam to the Fe obtained in step 1 3 o 4 In the dispersion liquid, ultrasonically stir at room temperature for 3.5-4.5 hours to obtain magnetic foam;

[0026] Step 3, add the magnetic foam obtained in step 2 into the SDBS solution, stir it ultrasonically for 10-20 minutes, and then transfer it into a three-necked flask, wherein the mass ratio of SDBS to water is 1:100;

[0027] Step 4, heating the mixed solution obtained in step 3 in a water bath, increasing the heating temperature of the water bath to 65-75°C, adding St, DVB and AIBN, so that the mass ratio of AIBN to St to DVB is 1:(6.75-12):( 67.5~120), the reaction time is 5.5~6.5h...

Embodiment 1

[0029] The first step: 10 mL of Fe coated with hollow oleic acid with a mass concentration of 2.5 mg / mL 3 o 4 Deionized aqueous solution, sonicated at 25°C for 20 min, to form hollow oleic acid-coated Fe 3 o 4 Dispersions;

[0030] In the second step, the clean foam cut into (3cm×1.5cm×1.5cm) was added to the hollow oleic acid-coated Fe obtained in the first step 3 o 4 In the dispersion, ultrasonically stir for 3.5 hours at room temperature;

[0031] In the third step, add the magnetic foam obtained in the second step into 50mL of an aqueous solution in which 500mg of SDBS is dissolved, stir ultrasonically for 10min, and then transfer it into a three-necked flask;

[0032] In the fourth step, the heating temperature of the water bath in the third step was increased to 65°C, and 3 mL of St, 0.3 mL of DVB and 30 mg of AIBN were added, and the reaction time was 5.5 h. °C drying to obtain magnetic polystyrene foam.

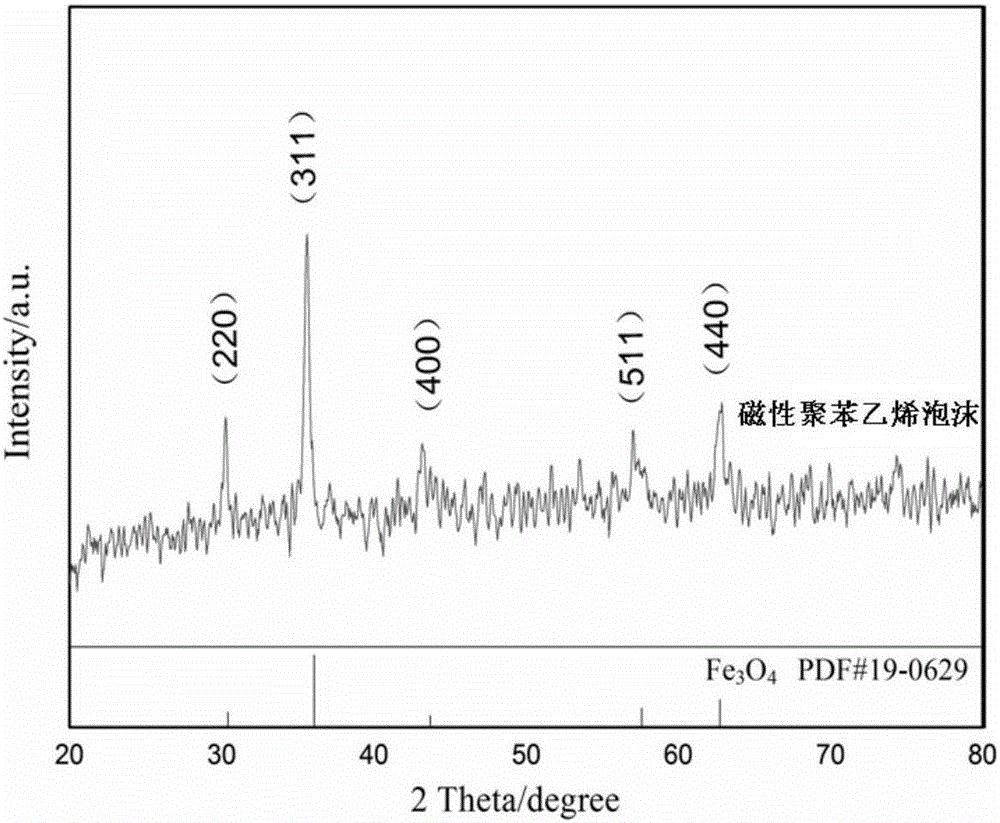

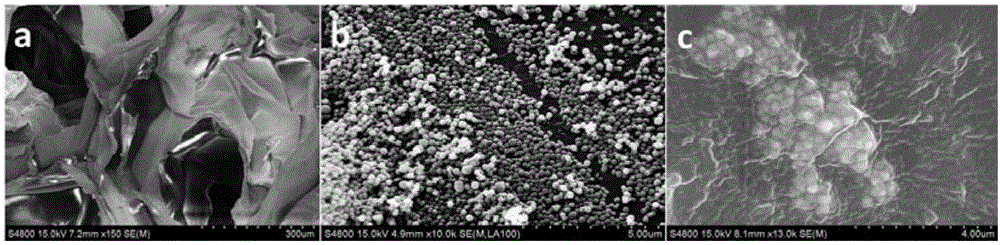

[0033] The magnetic polystyrene foam that embodiment 1 ga...

Embodiment 2

[0035] The first step: 12 mL of Fe coated with hollow oleic acid with a mass concentration of 2.5 mg / mL 3 o 4 Deionized aqueous solution, sonicated at 30°C for 15 min to form hollow oleic acid-coated Fe 3 o 4 Dispersions;

[0036] In the second step, the clean foam cut into (3cm×1.5cm×1.5cm) was added to the hollow oleic acid-coated Fe obtained in the first step 3 o 4 In the dispersion, ultrasonically stir for 4 hours at room temperature;

[0037] In the third step, add the magnetic foam obtained in the second step to 55 mL of an aqueous solution in which 550 mg of SDBS is dissolved, stir it ultrasonically for 15 minutes, and then transfer it into a three-necked flask;

[0038] In the fourth step, the heating temperature of the water bath in the third step was increased to 70°C, and 3.5mL of St, 0.35mL of DVB and 35mg of AIBN were added, and the reaction time was 6h. °C drying to obtain magnetic polystyrene foam.

[0039] Clean foam, magnetic foam and the magnetic polys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com