Environment-friendly heavy metal repairing agent, application thereof and slow-releasing heavy metal repairing fertilizer

A technology of heavy metal and repairing agent, applied in application, potash fertilizer, organic fertilizer and other directions, can solve the problems of many raw materials, high production cost and low economic benefit, and achieve the effects of simple preparation process, low production cost and good adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

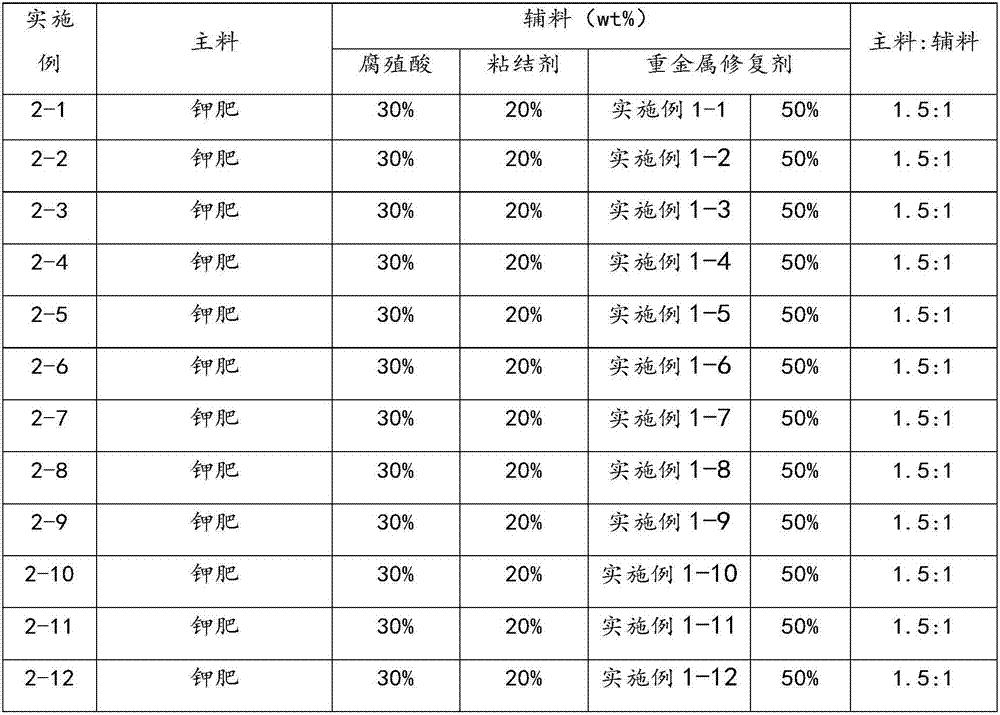

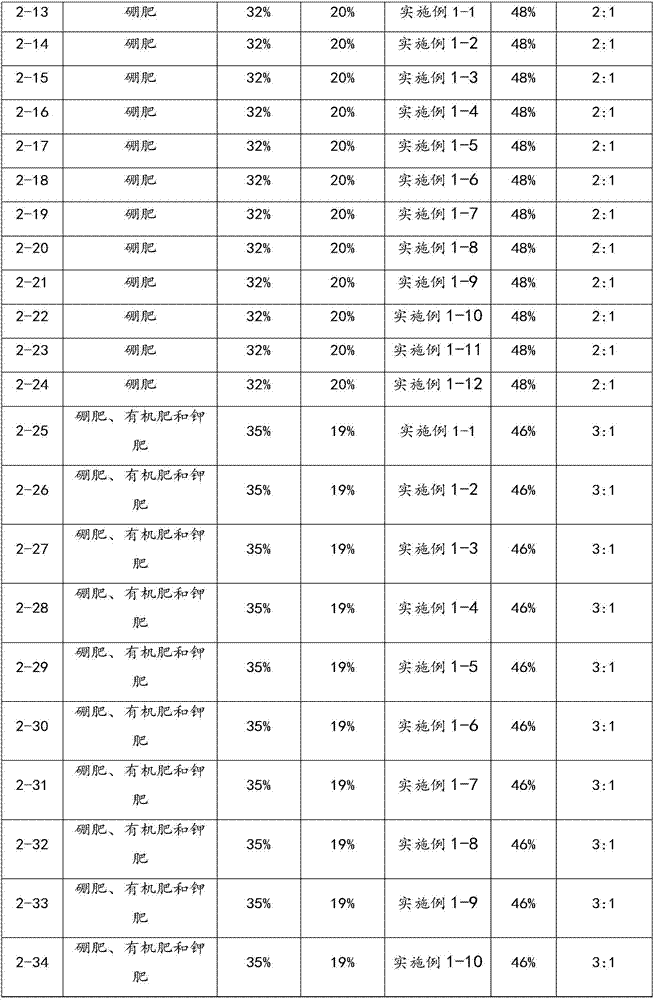

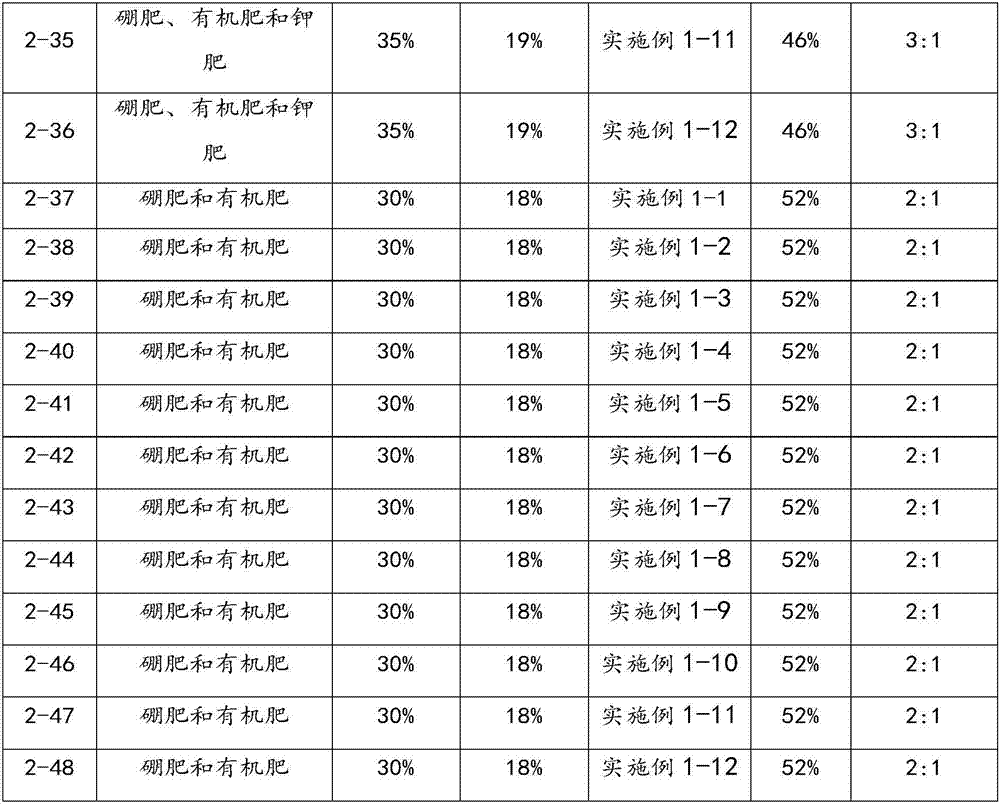

[0045] The preparation method of the slow-release heavy metal restoration fertilizer of the embodiment of the present invention comprises the following steps:

[0046] Step 2-1: Prepare the main material granules

[0047] It is prepared into granules by using at least one of organic fertilizer, potash fertilizer and boron fertilizer as raw material. When carrying out this step, it can be carried out according to the conventional steps of preparing fertilizer granules, or directly purchased on the market.

[0048] Step 2-2: Preparation of excipients

[0049] Take the humic acid and the binder according to the embodiment of the present invention, wherein the humic acid accounts for 30-35% of the total weight of the auxiliary materials, and the binder accounts for 15-20% of the total weight of the auxiliary materials. The humic acid and the binder are mixed in a mixer according to the aforementioned weight percentage to prepare a slurry for use.

[0050] Step 2-3: Film formati...

Embodiment 1-1

[0057] After pretreatment, oyster shells are roasted protectively at a roasting temperature of 600°C and a roasting time of 12 minutes. When feeding, the flow rate of the oyster shells is controlled to be 0.2m 3 / min, the rotational speed of the roasting equipment is 25r / min. After roasting, the water content in the oyster shell is 10% (percentage by weight). The oyster shells were subjected to the first cooling treatment and the second cooling treatment respectively, wherein the natural cooling time of the first cooling treatment was 10 minutes, and the condition of the second cooling treatment was cooling at a cooling rate of 15°C / min for 15 minutes. Then, the oyster shells are crushed, and the oyster shell powders with different particle sizes are screened out by winnowing. Then, oyster shell powders of different sizes were prepared into heavy metal restoration agents, which included primary powder, secondary powder, tertiary powder and quaternary powder. The first-grade ...

Embodiment 1-2

[0059] After pretreatment, the oyster shells are roasted protectively at a roasting temperature of 650°C and a roasting time of 10 minutes. When feeding, the flow rate of the oyster shells is controlled to be 0.3m 3 / min, the rotational speed of the roasting equipment is 30r / min. After roasting, the water content in the oyster shell is 9.5% (percentage by weight). The oyster shells were subjected to the first cooling treatment and the second cooling treatment respectively, wherein the natural cooling time of the first cooling treatment was 14 minutes, and the condition of the second cooling treatment was cooling at a cooling rate of 17°C / min for 11 minutes. Then, the oyster shells are crushed, and the oyster shell powders with different particle sizes are screened out by winnowing. Then, oyster shell powders of different sizes were prepared into heavy metal restoration agents, which included primary powder, secondary powder, tertiary powder and quaternary powder. The first g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com