Universal toothed chain type stepless speed change transmission device

A technology of stepless speed change and transmission device, which is applied in portable hoisting devices, transmission chains, hoisting devices, etc., can solve the problems of limited speed ratio torque and inability to enter the field of automobile transmission, and achieve low cost, simple structure, and transmission high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

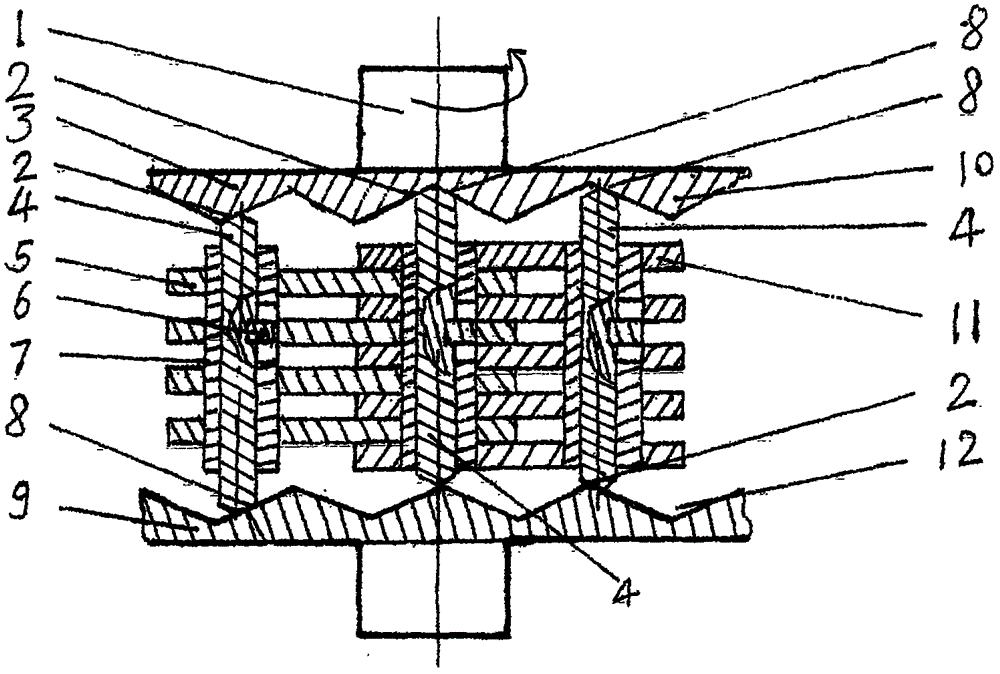

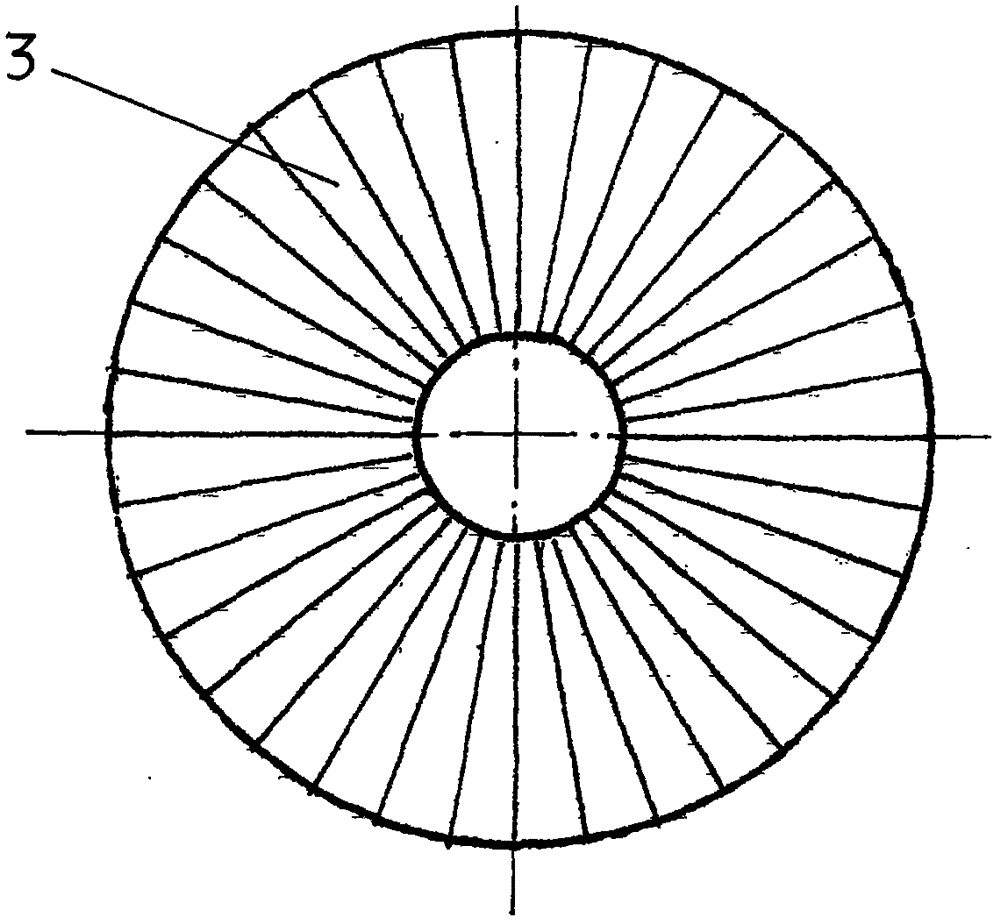

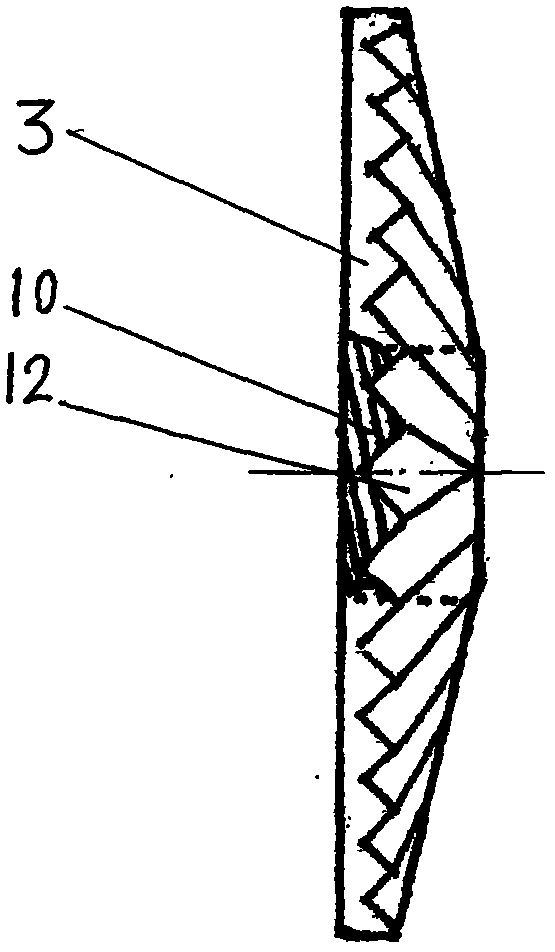

[0019] exist figure 1 The front contact surface (2) of the middle chain pin (4) meshes with the peak (10) of the left cone (3), and the peak (10) radially pushes the front contact surface (2) of the chain pin (4) to rotate, and the other end of the chain pin (4) The contact between the rear contact surface (8) and the peak (10) is an axial jacking force, that is, there is no radial thrust nor radial pull. Only one side of the helical bevel teeth at the two ends of the chain pin (4) is radial thrust, and the other side does not have radial thrust and pulling force, and only the axial jacking force is follow-up. refer to Figure 5 Each chain pin (4) has four contact surfaces of bevel teeth at both ends. When two front contact surfaces (2) and two rear contact surfaces (8) are in contact with the left and right cones, there is only one front contact surface (2) and one The rear contact surface (8) is in contact with the peak and valley teeth of the left and right cones, and no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com