Single-suction 2G screw pump shell

A screw pump and casing technology, applied in pump components, rotary piston/oscillating piston pump components, machines/engines, etc. problems, to achieve the effect of not easy to loosen and leak, good economic and social benefits, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

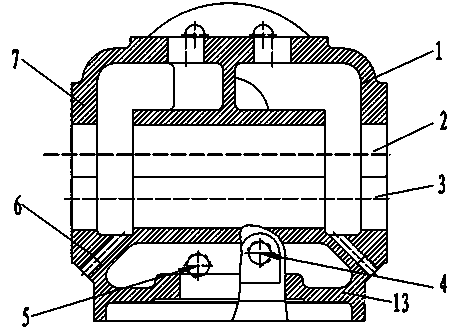

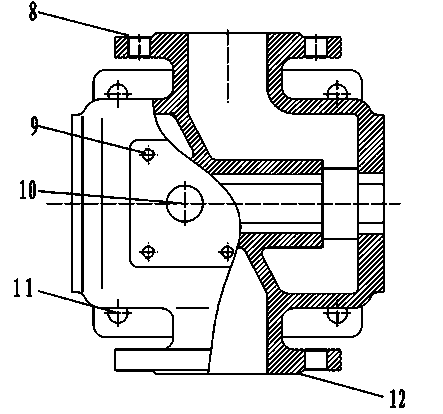

[0011] A single-suction 2G screw pump casing, the casing is an integral structure, the front end of the casing is a front end cover 1, and the rear end is a rear end cover 7; the central part of the casing is opened with a driving shaft hole 2 and a driven shaft hole through the front and back. 3. The two sides of the shell are respectively connected to the outlet flange end 8 and the inlet flange end 12; the lower part of the shell is provided with a heating air inlet 4, a heating air outlet 5, and a drain oil hole 6. A safety valve threaded hole 9 and a safety valve pressure relief hole 10 are provided on the upper part of the housing. The lower part of the shell is provided with a partial annular interlayer 13, which can increase the heating area of the single-suction 2G screw pump, and is suitable for the transportation of high-viscosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com