Non-circular gear planetary gear train hydraulic motor

A technology of planetary gear trains and non-circular gears, which is applied in the field of hydraulic motors, the basic hydraulic components of the machinery industry, can solve the problems of no instantaneous motion law, many design parameter variables, and few degrees of freedom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

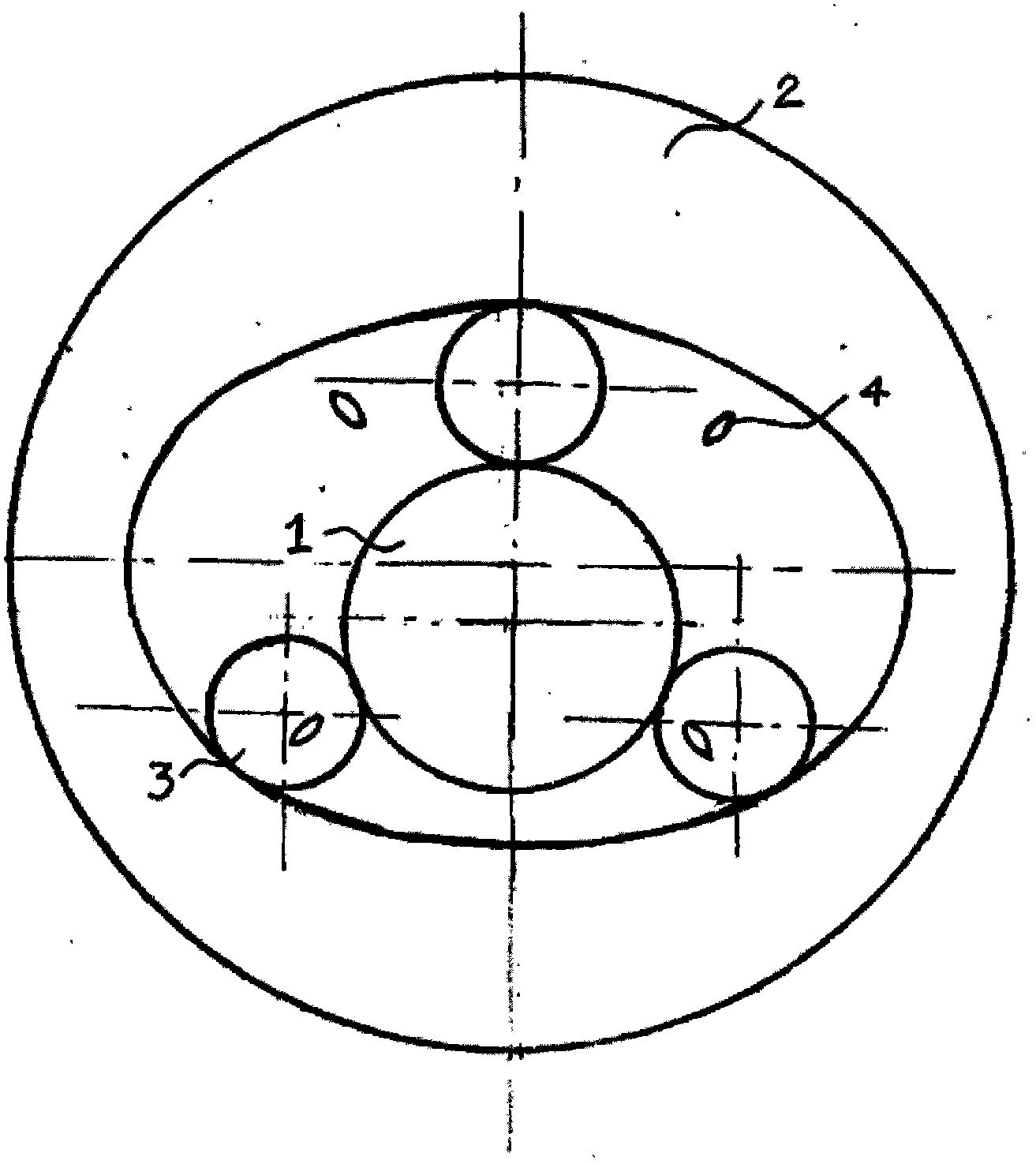

[0017] Now one of the simplest embodiments of the present invention is described as follows in conjunction with the accompanying drawings:

[0018] figure 1 It represents a hydraulic motor with the simplest non-circular gear train structure consisting of a sun gear 1 with an eccentric circle as the rotor, a peripheral wheel 2 with internal teeth with an ellipse as the stator, and three planetary cylindrical gears 3 .

[0019] The eccentric circle radius of the sun gear R1=200mm, the eccentric distance e=80mm, the number of teeth Z1=100;

[0020] The radius of the planetary cylindrical gear R0 = 90mm, the number of planetary gear teeth Z0 = 45, the modulus m = 4;

[0021] Its peripheral wheel with external teeth its elliptic pitch curve 4 The short diameter R2min=300mm, the long diameter R2max=460mm, the number of teeth Z2=200, and the pressure angle is 20°;

[0022] The positions of the four distribution holes 4 on the distribution plate are evenly and symmetrically distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com