A kind of nb-si-ti-b-al-cr composite material and preparation method thereof

A composite material, nb-si-ti-b-al-cr technology, applied in the field of composite material preparation, can solve the requirements that cannot meet the requirements of ultra-high temperature and harsh environment use, limit the freedom of material components and microstructure design, and restrict Aerospace technology development and other issues, to achieve unique physical properties, improve high temperature oxidation resistance, high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

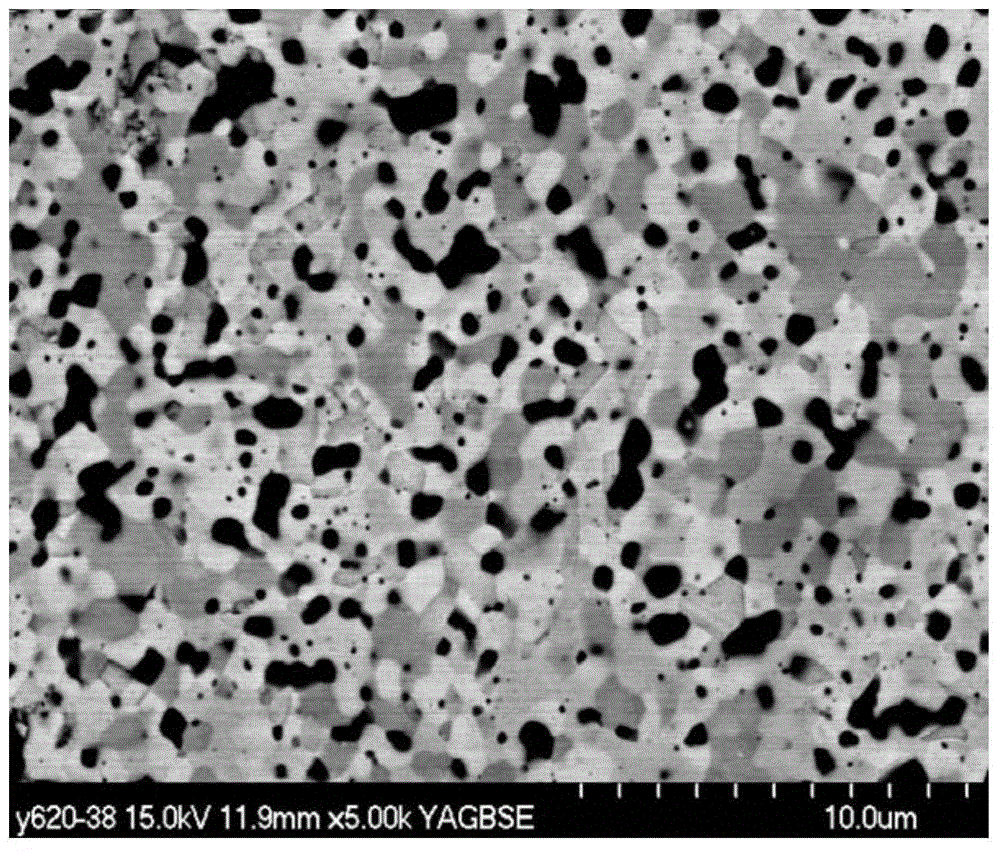

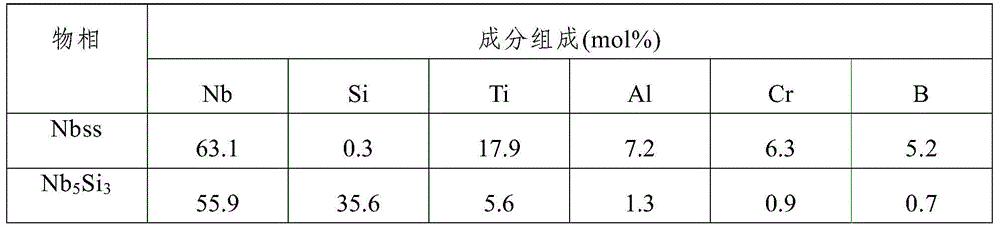

Image

Examples

Embodiment 1

[0023] In this example, the Nb-Si-Ti-B-Al-Cr composite material is made of the following atomic percentages: Si 15%, Ti 15%, B 4%, Al 6%, Cr 5%, and the balance is Nb and not Avoid impurities.

[0024] The method for preparing the Nb-Si-Ti-B-Al-Cr composite material in this embodiment comprises the following steps:

[0025] Step 1. Put silicon powder, titanium powder, boron powder, aluminum powder, chromium powder and niobium powder in a ball mill, mix them uniformly by wet ball milling, then dry them under vacuum conditions, and pulverize them to obtain mixed powder material; preferably, the mass purity of the silicon powder is not less than 99.99%, the mass purity of the titanium powder is not less than 99.99%, the mass purity of the boron powder is not less than 99.9%, and the mass purity of the aluminum powder is not less than 99%, the mass purity of the chromium powder is not less than 99.9%, the mass purity of the niobium powder is not less than 99.9%, the particle size...

Embodiment 2

[0033] In this example, the Nb-Si-Ti-B-Al-Cr composite material is made of the following atomic percentages: Si 6%, Ti3%, B 1%, Al 3%, Cr 2%, and the balance is Nb and not Avoid impurities.

[0034] The method for preparing the Nb-Si-Ti-B-Al-Cr composite material in this embodiment comprises the following steps:

[0035] Step 1. Put silicon powder, titanium powder, boron powder, aluminum powder, chromium powder and niobium powder in a ball mill, mix them uniformly by wet ball milling, then dry them under vacuum conditions, and pulverize them to obtain mixed powder material; preferably, the mass purity of the silicon powder is not less than 99.99%, the mass purity of the titanium powder is not less than 99.99%, the mass purity of the boron powder is not less than 99.9%, and the mass purity of the aluminum powder is not less than 99%, the mass purity of the chromium powder is not less than 99.9%, the mass purity of the niobium powder is not less than 99.9%, the particle size of...

Embodiment 3

[0039] In this example, the Nb-Si-Ti-B-Al-Cr composite material is made of the following atomic percentages: Si 20%, Ti 25%, B 10%, Al 15%, Cr 10%, and the balance is Nb and not Avoid impurities.

[0040] The method for preparing the Nb-Si-Ti-B-Al-Cr composite material in this embodiment comprises the following steps:

[0041] Step 1. Put silicon powder, titanium powder, boron powder, aluminum powder, chromium powder and niobium powder in a ball mill, mix them uniformly by wet ball milling, then dry them under vacuum conditions, and pulverize them to obtain mixed powder material; preferably, the mass purity of the silicon powder is not less than 99.99%, the mass purity of the titanium powder is not less than 99.99%, the mass purity of the boron powder is not less than 99.9%, and the mass purity of the aluminum powder is not less than 99%, the mass purity of the chromium powder is not less than 99.9%, the mass purity of the niobium powder is not less than 99.9%, the particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com